Motor rotor and motor

A technology of motor rotor and motor stator, applied in asynchronous induction motors, electric components, electrical components, etc., can solve the problems of increasing load stray loss, weakening harmonic magnetic field, increasing iron core transverse current, etc., to avoid axial The effect of uneven distribution of magnetic field, reduction of axial pulse amplitude, and improvement of magnetic field sine degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

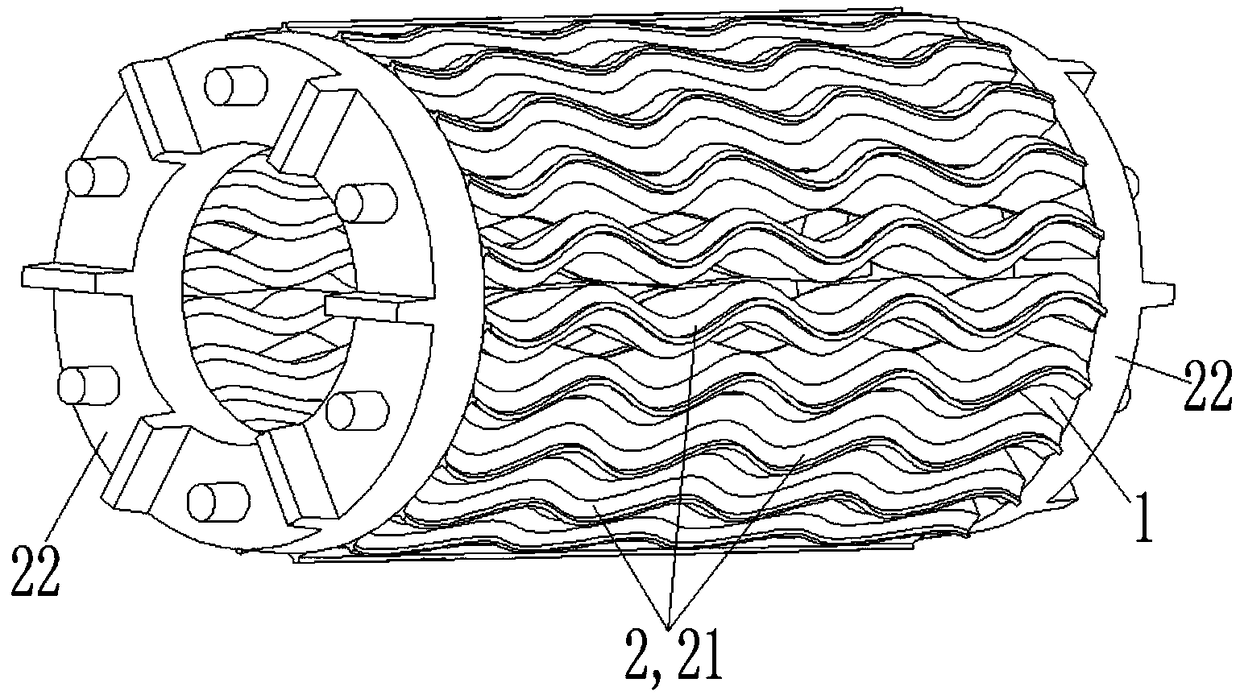

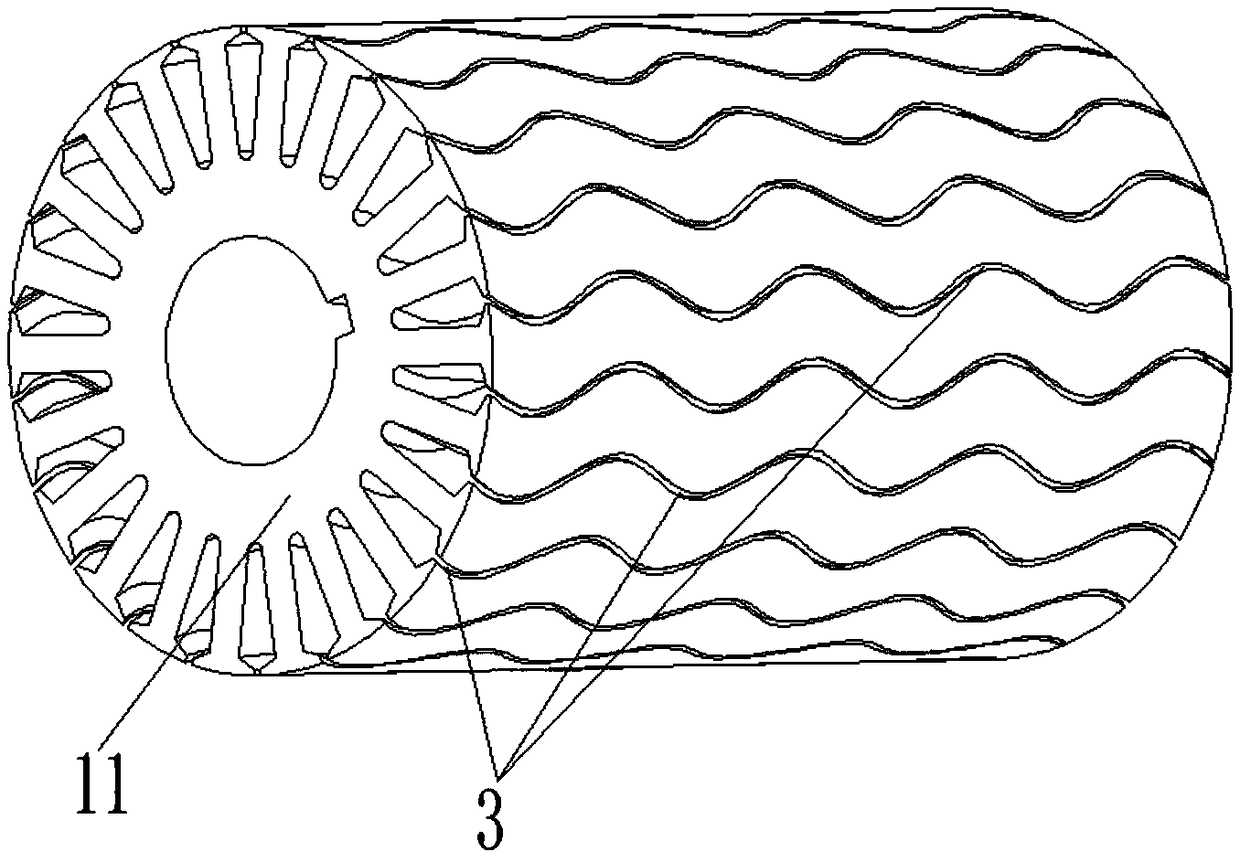

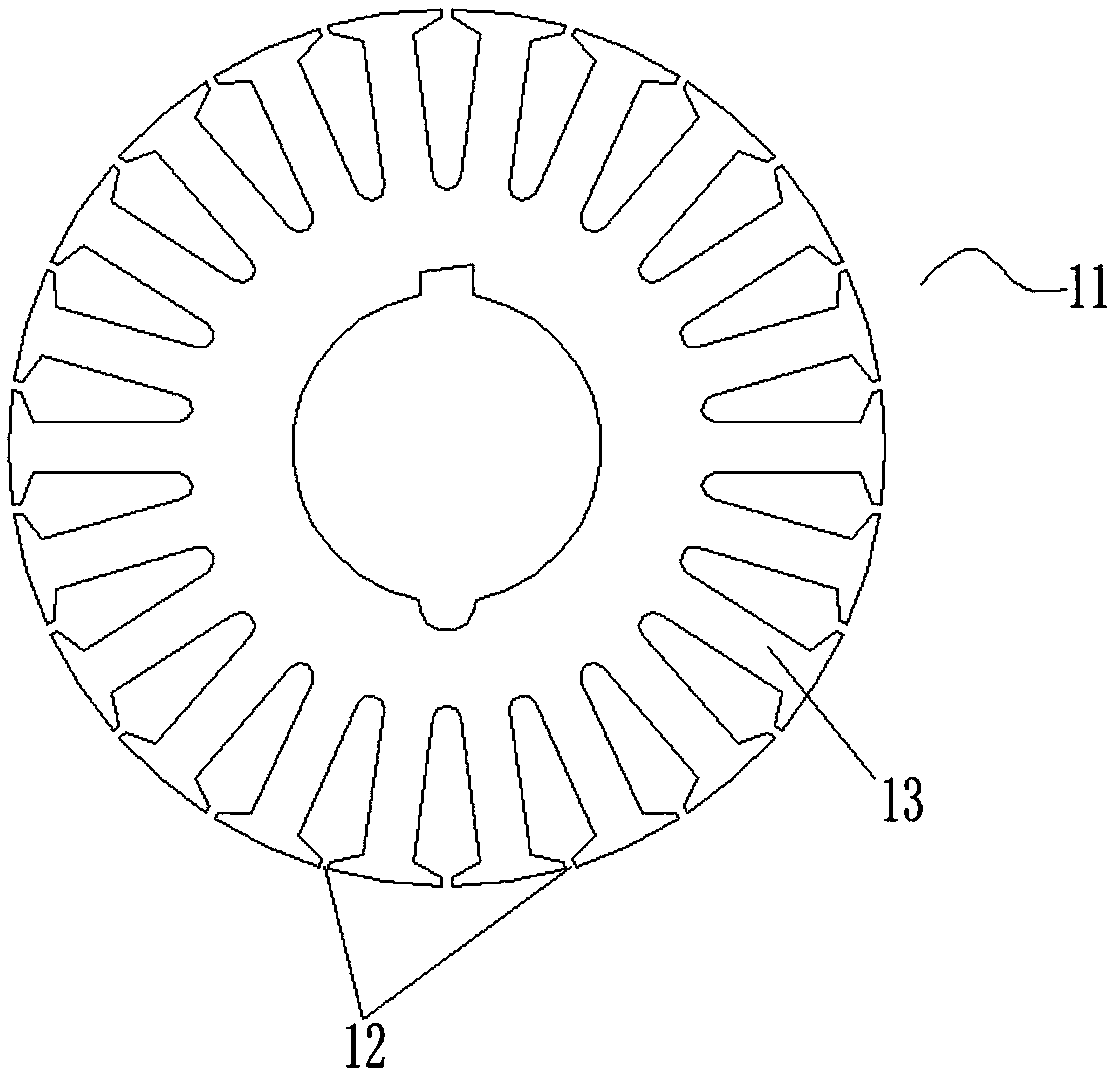

[0023] see in conjunction Figures 1 to 4 As shown, according to an embodiment of the present invention, a motor rotor is provided, including an iron core 1 and a squirrel cage 2. There are a plurality of inclined slots 3 on the outer peripheral wall of the iron core 1, and the plurality of inclined slots 3 are parallel to each other. The line between the starting point and the end point of the chute 3 forms an included angle with the axis of the iron core 1. The chute 3 is a sine wave chute, and the sine wave chute is formed by the iron core in the shape of a sine wave. 1 extends from one end to the other end, and the squirrel cage 2 has a plurality of guide bars 21, the shape of each guide bar 21 is matched with the corresponding chute 3, and each guide bar 21 is correspondingly located in each in chute 3. In this technical solution, since the chute is a sine wave chute, and the shape of the guide bar 21 is adapted to it, that is, the guide bar 21 also extends in the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com