Ultrafine fiber production method

A technology of ultra-fine fibers and manufacturing methods, which is applied in the fields of fiber processing, rayon manufacturing, and fiber chemical characteristics, and can solve problems such as difficulty in application, high manufacturing costs, and difficulty in improving manufacturing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

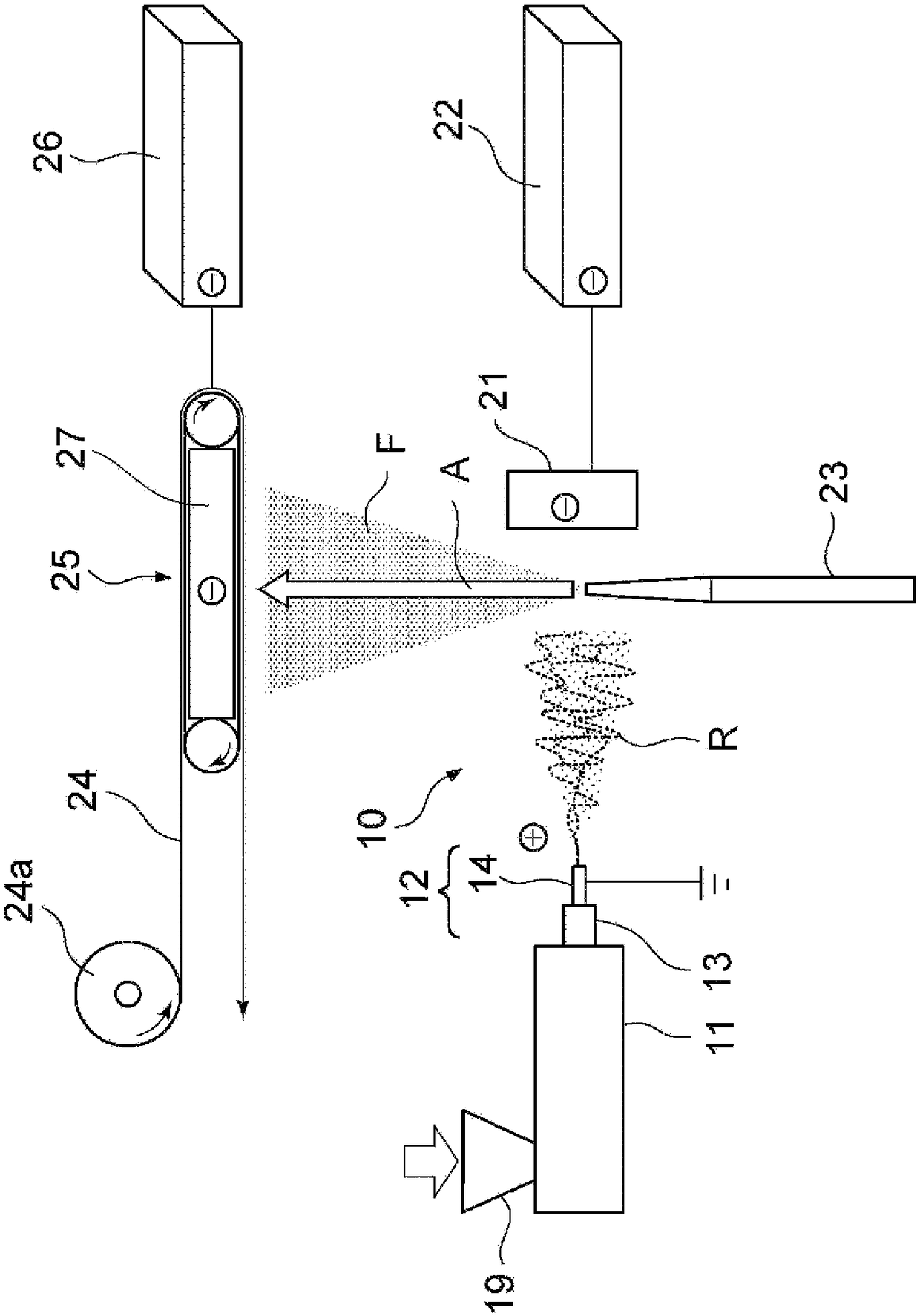

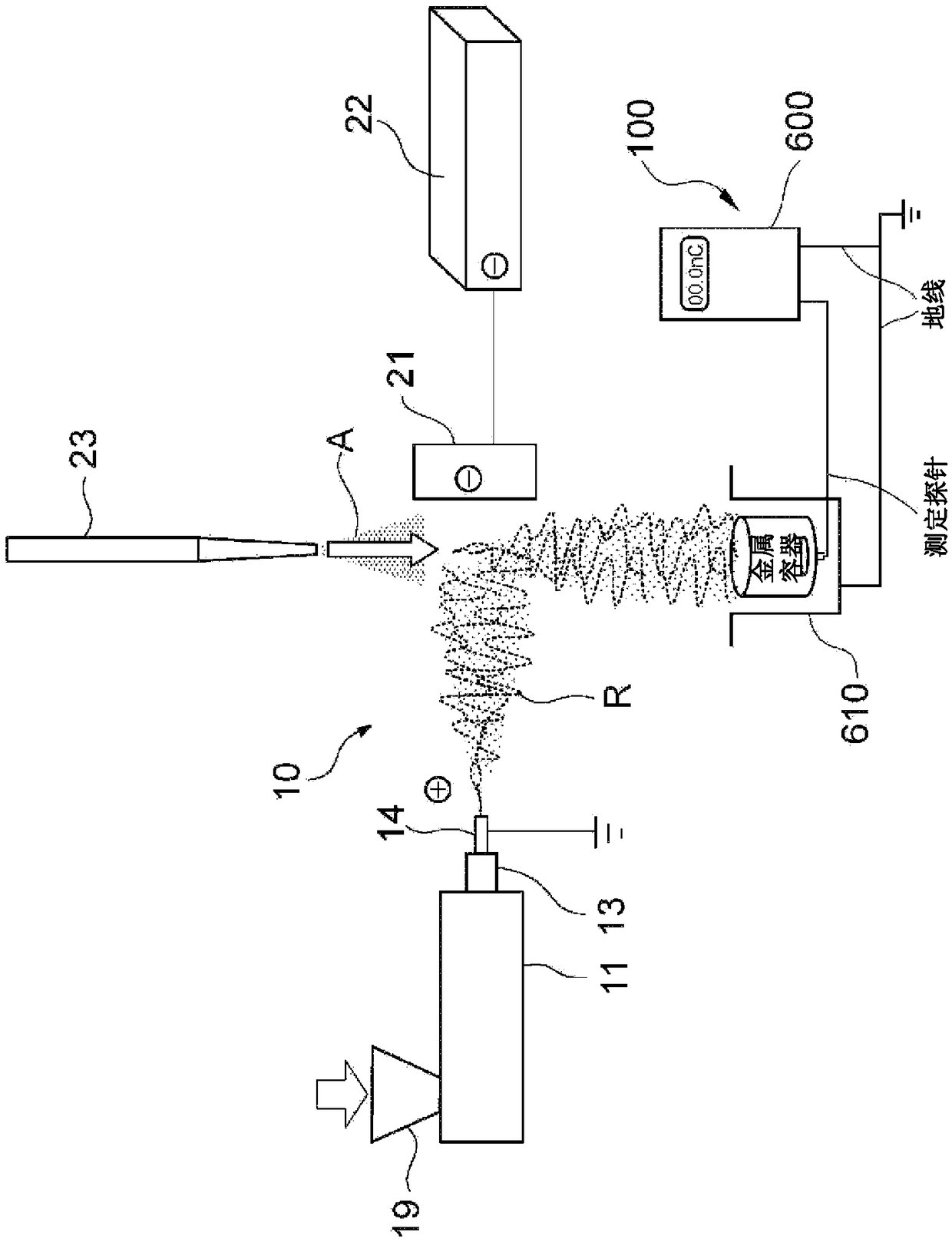

[0123] use figure 1 The melt electrospinning apparatus 10 shown produces ultrafine fibers made of a raw material resin (resin composition) in which polypropylene (PP) and additives are mixed. As the polypropylene, PolyMirae's MF650Y (melting point: 160° C.) was used. As an additive, Acrybase (registered trademark) FCA-201-PS type of Fujikura Kasei Co., Ltd., which is a styrene acrylic resin having a quaternary ammonium salt group, was used. The decomposition temperature of this additive is 276°C. The additive was blended 5% with respect to the total mass of the polypropylene resin and the additive. The electrical impedance of the raw material resin is shown in Table 1. The discharge nozzle base 13 and the discharge nozzle tip 14 in the melt electrospinning device 10 are made of stainless steel (SUS303). The heating temperature of the cylinder in the casing 11 of the melt electrospinning device 10 was set to 220°C. The raw material resin is melt-kneaded in the casing 11 . ...

Embodiment 2 to 4

[0125] Ultrafine fibers were produced in the same manner as in Example 1 except that the additives were replaced with the components described in Table 1. The average fiber diameter of the ultrafine fibers was 2040 nm. The decomposition temperature of the additive in Example 2 is 349°C, the decomposition temperature of the additive in Example 3 is 315°C, and the decomposition temperature of the additive in Example 4 is 329°C.

Embodiment 5

[0127] Ultrafine fibers were produced in the same manner as in Example 2, except that the compounding amounts of the additives in Example 2 were replaced with the compounding amounts described in Table 1. The average fiber diameter of the ultrafine fibers was 1270 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fiber diameter | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Average fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com