Warp-knitted fabric and medical material

A technology of warp knitted fabrics and medical materials, applied in the field of warp knitted fabrics and medical materials, can solve the problem that the mesh cannot fully follow the enlargement of organs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0190] Examples are described below, but are not limited thereto.

[0191]

[0192] [Making of warp knitted fabric]

[0193] In the production of warp-knitted fabrics, first, yarns made of polylactic acid (Teijin, 33T12) as yarns made of bioabsorbable materials and yarns made of non-bioabsorbable materials are separated using a warping machine. Yarns made of polyethylene terephthalate (Toray, 33T12, type 262) were wound on the warp beam by the number of yarns used in the width. Next, the wound yarn is mounted on a knitting machine (tricot machine, 32 gauge, 120 courses), so that it passes through the spacer held by the yarn path and enters the yarn guide needle (reed).

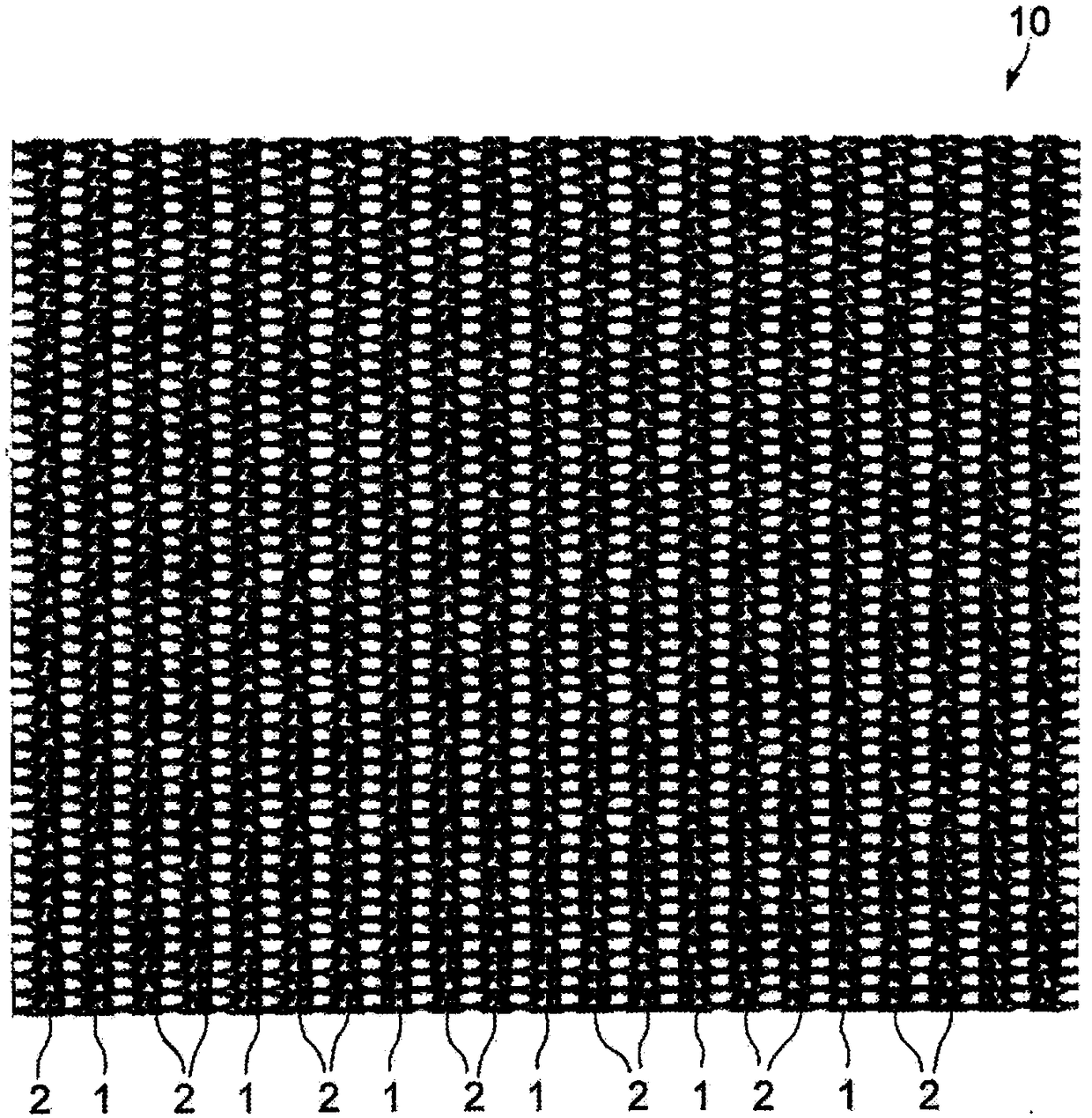

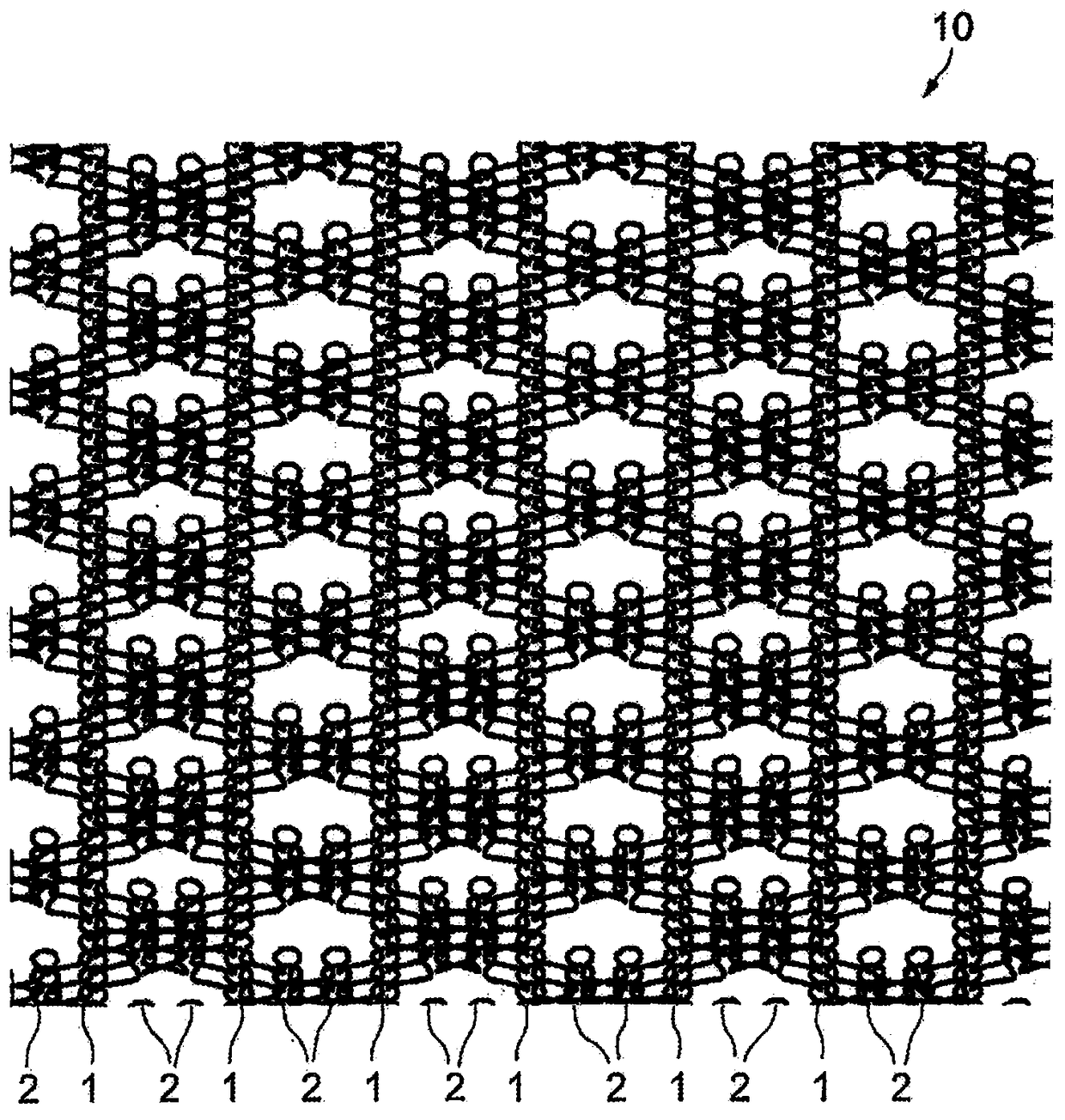

[0194] The knitting machine uses 4 pieces of reed (GB1-4), and weaves so that it becomes a plain knitted fabric in the state of knitting (编み上がった). At this time, yarns are arranged so that two reeds (GB1, GB2) form a full set (FULL.SET), and the remaining reeds (GB3, GB4) are also arranged so that two piece...

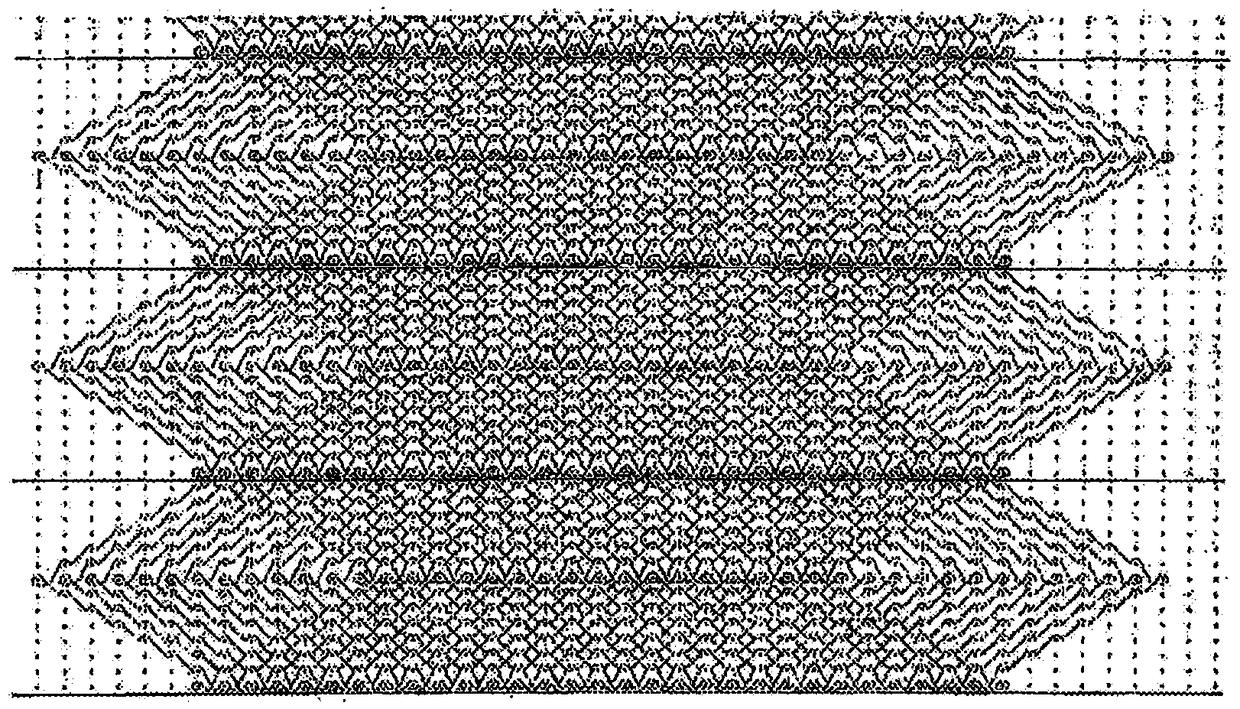

Embodiment 10

[0208] The warp knitted fabric obtained in Example 1 was cut into 100mm×100mm, immersed in 1M NaOH aqueous solution at 60°C for 2 hours to degrade the PLA of the warp knitted fabric, washed with ultrapure water, and dried to prepare test samples. Next, cut into 60mm x 60mm, and use a twin-screw extruder (manufactured by Toyo Seiki Co., Ltd.) to perform a constant-speed biaxial simultaneous tensile test in the longitudinal direction (MD) and transverse direction (TD) until the length doubles. . Distance between chucks: 45mm, speed: 50mm / min, temperature: 37°C.

Embodiment 11

[0210] Except that the course of the knitting machine was changed to 60 courses, a warp knitted fabric was produced in the same manner as in Example 1, and a test sample was prepared in the same manner as in Example 10 using the obtained warp knitted fabric, and a constant speed biaxial Simultaneous tensile test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com