Beef and vegetable nutrient noodles and production process thereof

A production process and nutrition surface technology, which is applied in the functions of food ingredients, food ingredients containing oligosaccharides, food science, etc., can solve the problems of general sensory properties, rough surface, and insufficient smoothness of the product, so as to achieve the goal of not breaking easily The effect of strips, good taste, and improved synchronization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: a kind of beef and vegetable nutritious noodles, each component and its corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0057] Step 1, accurately weigh each component, and sieve each component through a 14-mesh sieve to remove foreign matter and coarse particles;

[0058] Step 2, put 50% of the formula amount of wheat flour into the vacuum dough mixer, then add nutrient premix, beef powder, spinach powder, Chinese yam powder, fructooligosaccharide, and finally add the remaining 50% of the formula amount of wheat flour;

[0059] Step 3: Evacuate the vacuum dough mixer to -69kPa, add 28 parts of pure water, turn on the vacuum dough mixer for dough mixing, and form dough;

[0060] Step 4, discharging the dough onto the conveyor belt, keeping the dough in a relatively static condition for curing, the curing humidity is 50%, the curing temperature is below 27°C, and the curing time is 35min;

[0061] Step 5, us...

Embodiment 2-6

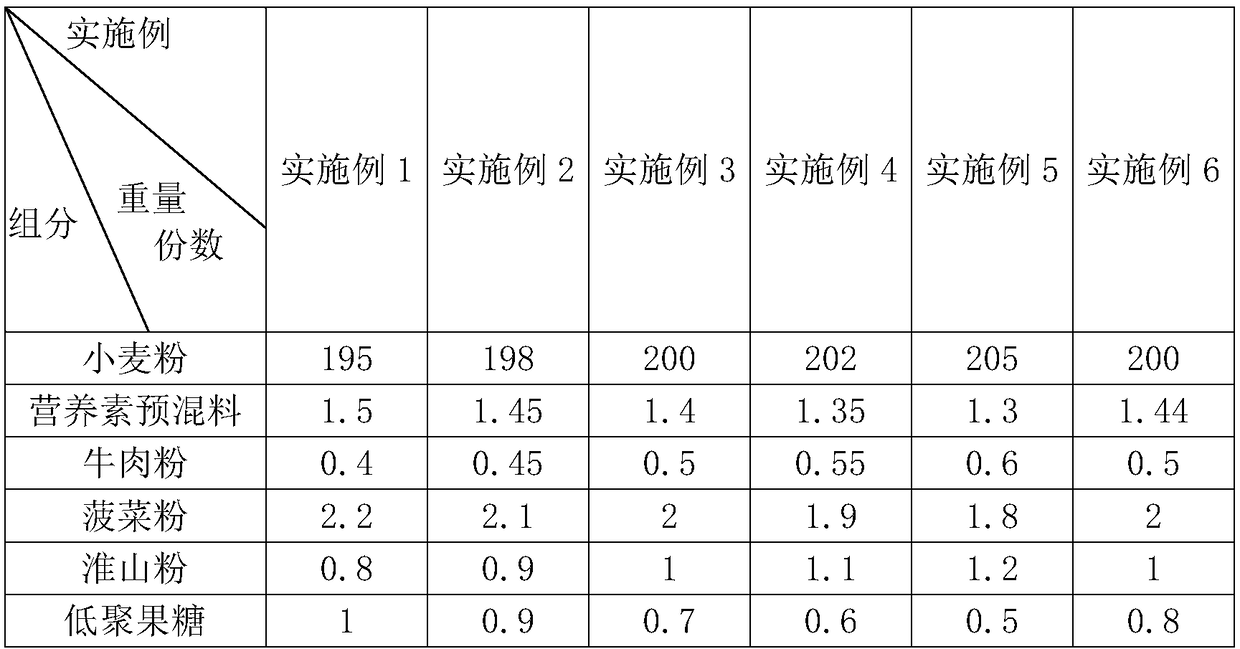

[0071] Example 2-6: a beef and vegetable nutritional noodle, the difference from Example 1 is that each component and its corresponding weight portion are shown in Table 1.

[0072] Each component and its parts by weight in the embodiment 1-6 of table 1

[0073]

Embodiment 7

[0074] Embodiment 7: a kind of beef and vegetable nutrition noodles, the difference from embodiment 1 is that step 3 specifically includes: vacuuming the vacuum dough mixer to -70kPa, adding 30 parts of pure water, turning on the vacuum dough mixer to carry out mixing. to form a dough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com