Novel kitchen waste treating system and utilizing method

A kitchen waste and treatment system technology, applied in the application, organic fertilizer, climate change adaptation and other directions, can solve the problems of high labor cost, large investment, large space occupation, etc., to reduce the probability of secondary pollution and reduce the environment. Pollution, the effect of improving application efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further described in detail below through examples, but the present invention is not limited only to the following examples.

[0043] The application of the present invention utilizes the main controller, that is, the electric control system or is called the electric control system PLC program (programmable logic controller (PLC), PLC controller.), instruments and meters, automatic valves, to control all equipment motors, so that the operation is stable and reliable, Improve efficiency, reduce labor costs, and avoid problems caused by human errors.

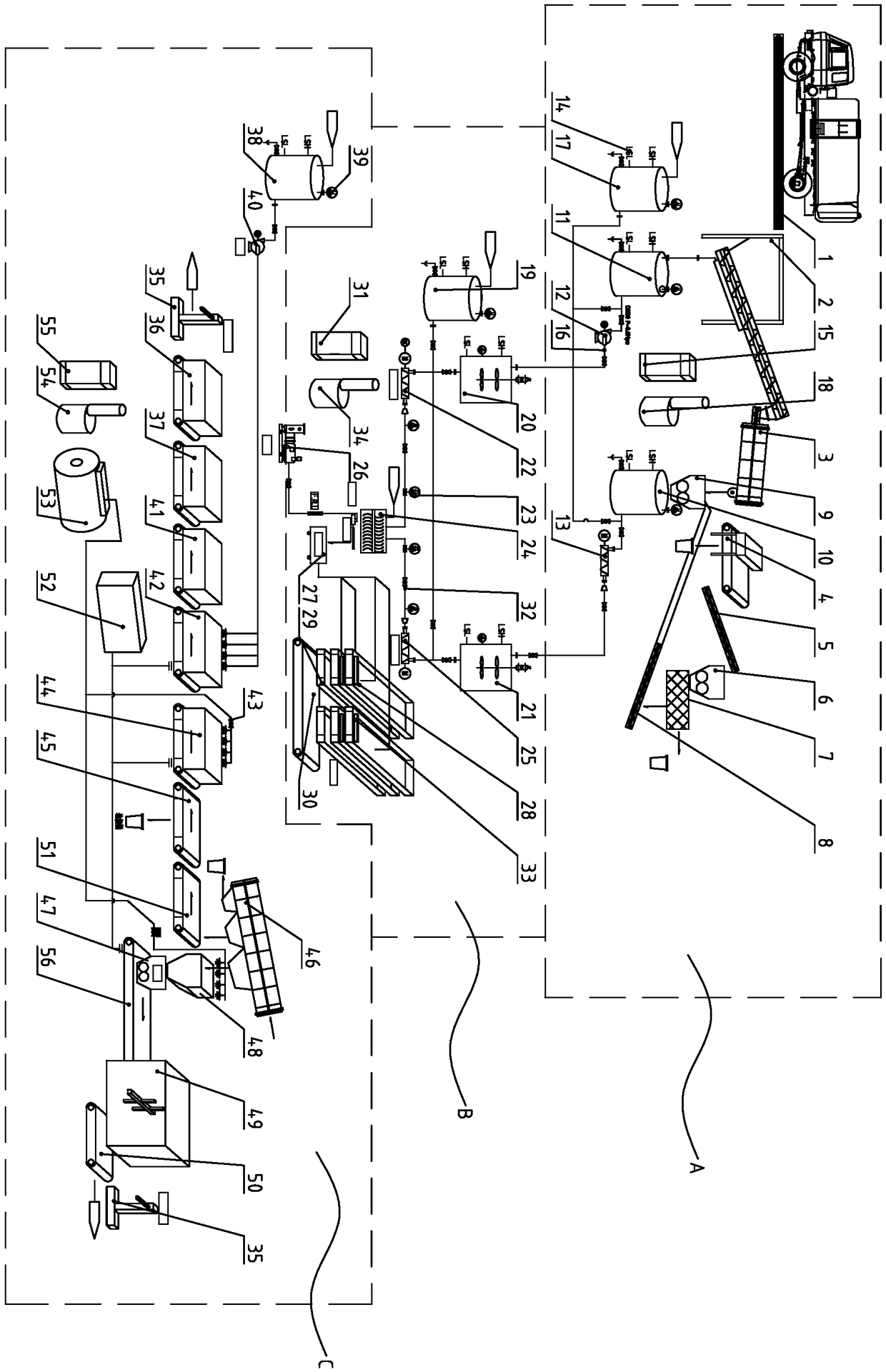

[0044] as attached figure 1 Shown, a kind of novel kitchen waste treatment system of the present invention, this system comprises pretreatment system A, insect rearing system B and back-end treatment system C;

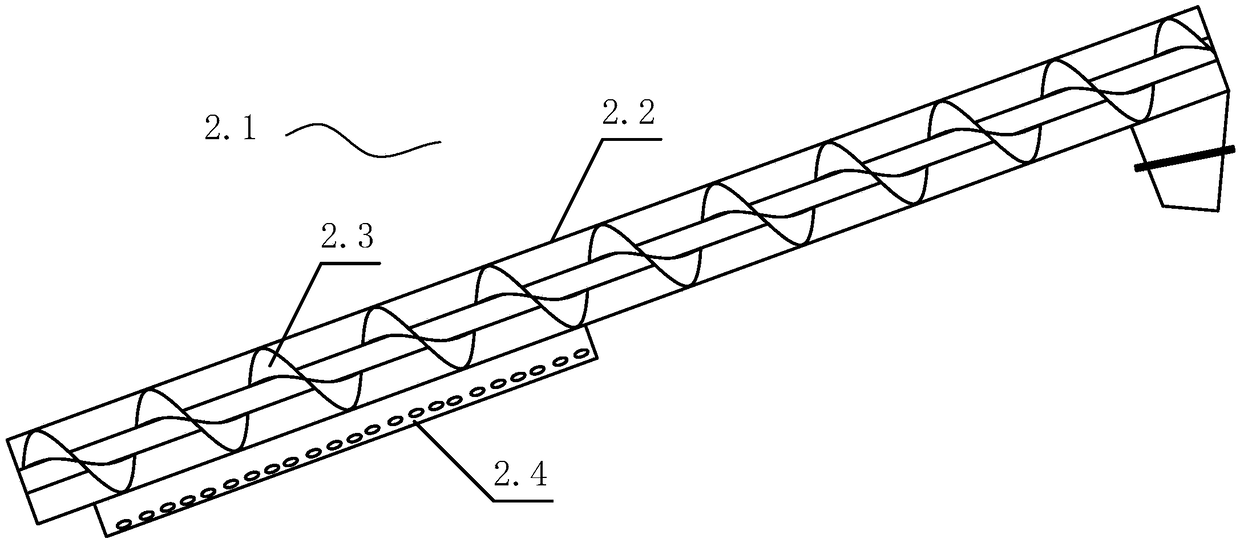

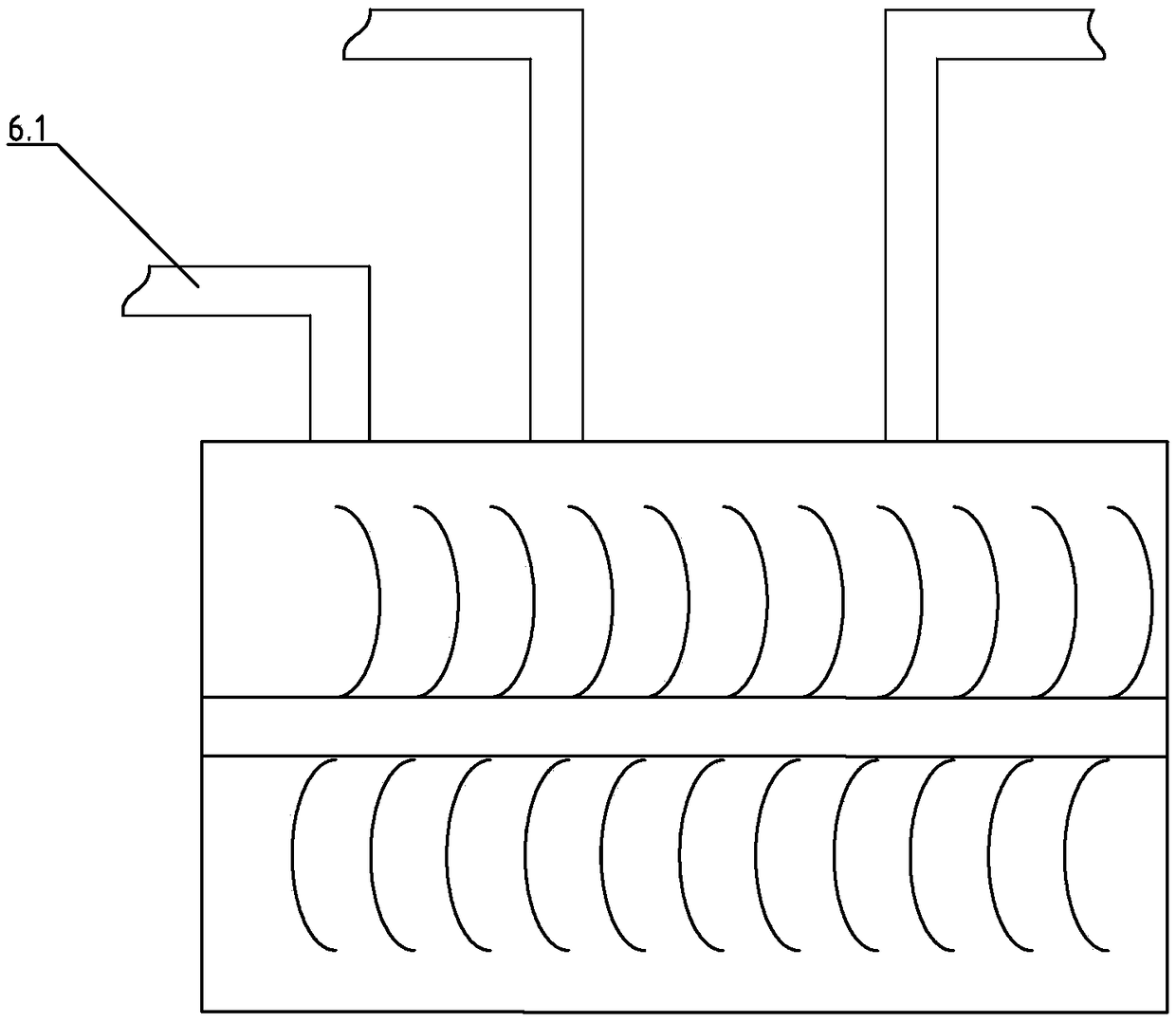

[0045] The pretreatment system includes a storage bin 2 connected in sequence, a large drum sorter 3, a metal detector 4, a large material conveying screw 5, a shredder 6, a small drum sort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com