An environmentally friendly green printing process for corrugated cardboard

A corrugated cardboard, green technology, applied in the field of corrugated cardboard, can solve the problems of peeling off the face paper or re-shredding, complex process, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation process of waterproof colloid is as follows:

[0019] ① Prepare a sodium hydroxide solution with a concentration of 0.1mol / L, then add 24g of catechol solid into it, stir and dissolve to obtain 120mL of alkaline catechol solution;

[0020] ②Measure two-thirds of the alkaline catechol solution in step ①, raise the temperature to 55°C, add 80g of oxidized starch solution to it, stir while adding dropwise, and stir at constant temperature for 20-30min to obtain the primary crosslinking solution;

[0021] ③Keep the temperature constant, add the remaining alkaline catechol solution into the primary colloid solution, stir evenly, add 14g of glutaraldehyde solution, and stir at constant temperature for 50min to obtain the secondary crosslinking solution;

[0022] ④Raise the temperature to 60°C and slowly evaporate the solvent water in the secondary cross-linking solution until the secondary cross-linking solution is a viscous paste.

Embodiment 2

[0024] An environmentally friendly green printing process for corrugated cardboard, the specific printing process is as follows:

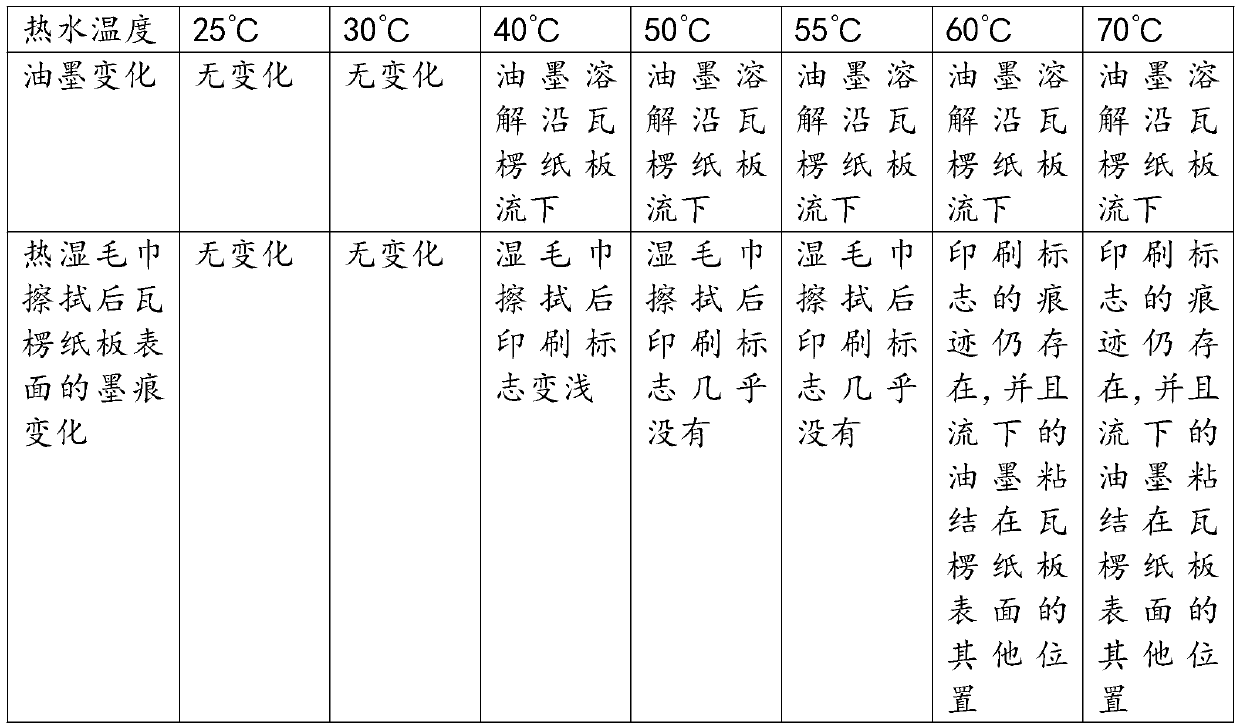

[0025] In the first step, add the prepared waterproof colloid into a high-pressure spray gun, spray it evenly on the surface of the corrugated cardboard, and then dry it in a drying room at 45°C until the waterproof colloid is solidified. At this time, a waterproof colloid layer is formed on the surface of the corrugated cardboard The thickness of the waterproof colloid layer is 0.8-1mm; the waterproof colloid layer softens when the temperature reaches above 60°C and has certain bonding properties;

[0026] The second step is to print on the waterproof colloidal layer on the surface of the corrugated cardboard by a cardboard printing machine. During the printing process, the temperature of the printing roller is controlled at 65°C. At this time, the waterproof colloidal layer has a certain viscosity and can fix the ink; the printing process The ink...

Embodiment 3

[0029] An environmentally friendly green printing process for corrugated cardboard, the specific printing process is as follows:

[0030] In the first step, add the prepared waterproof colloid into a high-pressure spray gun, spray it evenly on the surface of the corrugated cardboard, and then dry it in a drying room at 45°C until the waterproof colloid is solidified. At this time, a waterproof colloid layer is formed on the surface of the corrugated cardboard The thickness of the waterproof colloid layer is 0.8-1mm; the waterproof colloid layer softens when the temperature reaches above 60°C and has certain bonding properties;

[0031]The second step is to print on the waterproof colloidal layer on the surface of the corrugated cardboard by a cardboard printing machine. During the printing process, the temperature of the printing roller is controlled at 65°C. At this time, the waterproof colloidal layer has a certain viscosity and can fix the ink; the printing process The ink ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com