Rapid sanitary appliance production method

A production method and technology of sanitary ware, which is applied in the production of ceramic materials, household utensils, manufacturing tools, etc., can solve the problems of low drying pass rate of ceramic sanitary ware blanks, low production efficiency, high cracking rate of blanks, etc., and improve the drying pass rate , improve efficiency, and ensure traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0094] A rapid production method for sanitary ware, comprising the following steps:

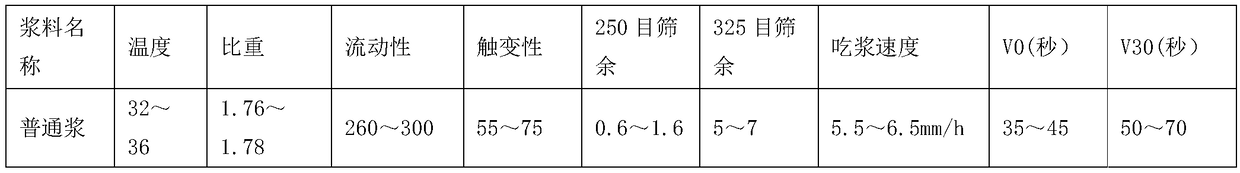

[0095]Grouting molding: the slurry is injected into the mold, demolded into a sanitary ware mud blank, and the existing ordinary mud is used for grouting molding;

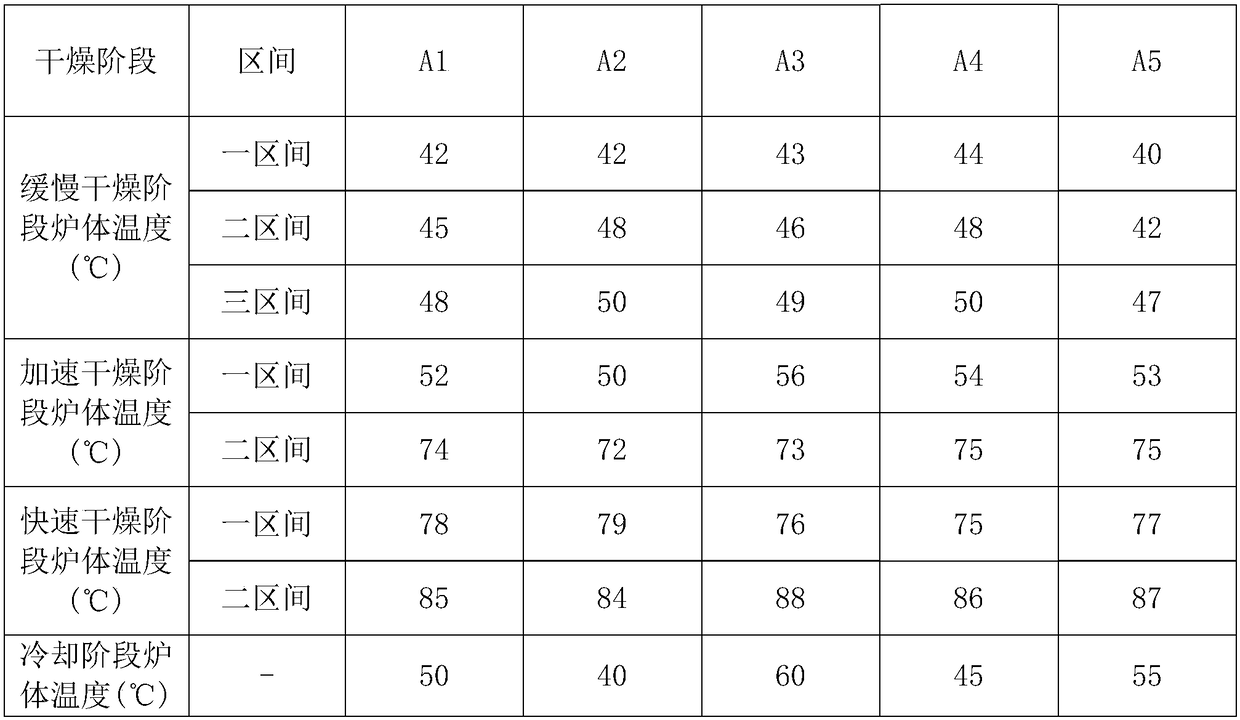

[0096] Microwave drying: The sanitary ware mud is sent to a microwave drying oven for drying. Microwave drying includes a slow drying stage, an accelerated drying stage, a fast drying stage and a cooling stage in sequence. The microwave drying cycle is 3-6 hours.

[0097] The control conditions of the slow drying stage are: turn on the microwave and the circulating air at the top of the microwave drying oven, the microwave power is 28-32KW, the temperature in the furnace is 40-50°C, and the relative humidity in the furnace is 8-52%; the slow drying stage includes Three intervals, the temperature in the furnace of the three intervals is 42°C, 45°C, and 48°C in sequence, and the relative humidity in the furnace of the three interval...

Embodiment B

[0117] The rapid production method of the sanitary ware in this embodiment is basically the same as that in Embodiment A, using the control parameters in serial numbers ①-⑤, the difference is that in the grouting molding step, high-pressure mud grouting is used;

[0118] The mass proportion of ridge material in the high-pressure mud raw material is 55-60%, and the mass proportion of particles smaller than 2 microns in the high-pressure mud raw material is less than 24%.

[0119] The parameters of high-pressure mud are: temperature 36-40, specific gravity 1.77-1.78, fluidity 290-320, thixotropy 85-105, 250 mesh sieve residue 0.8-1.8, 325 mesh sieve residue 6-8, slurry eating speed 7.5-8.5 mm / h, V0=40-45s, V30=75-85s.

[0120] The raw materials of high-pressure mud include ridge material and soft slurry material;

[0121] Ridge materials include 4-6% of Ningxiang soil, 7-11% of Zhangcun soil, 1-3% of potassium sand, 1-3% of sodium sand, 2-4% of magnesia clay and porcelain clay ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com