Prefabricated assembling staircase and connecting method thereof

A prefabricated assembly and staircase technology, applied in the direction of stairs, ladder-like structures, pedals, etc., can solve problems such as large space requirements, and achieve the effects of weight reduction, stable transmission, and reduced disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

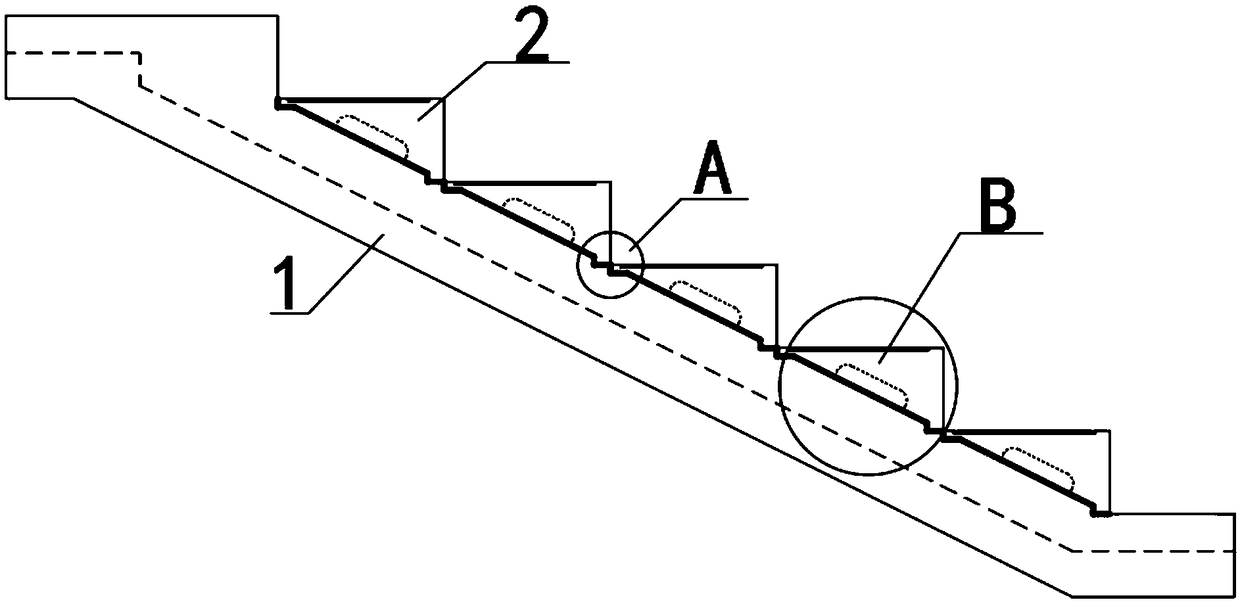

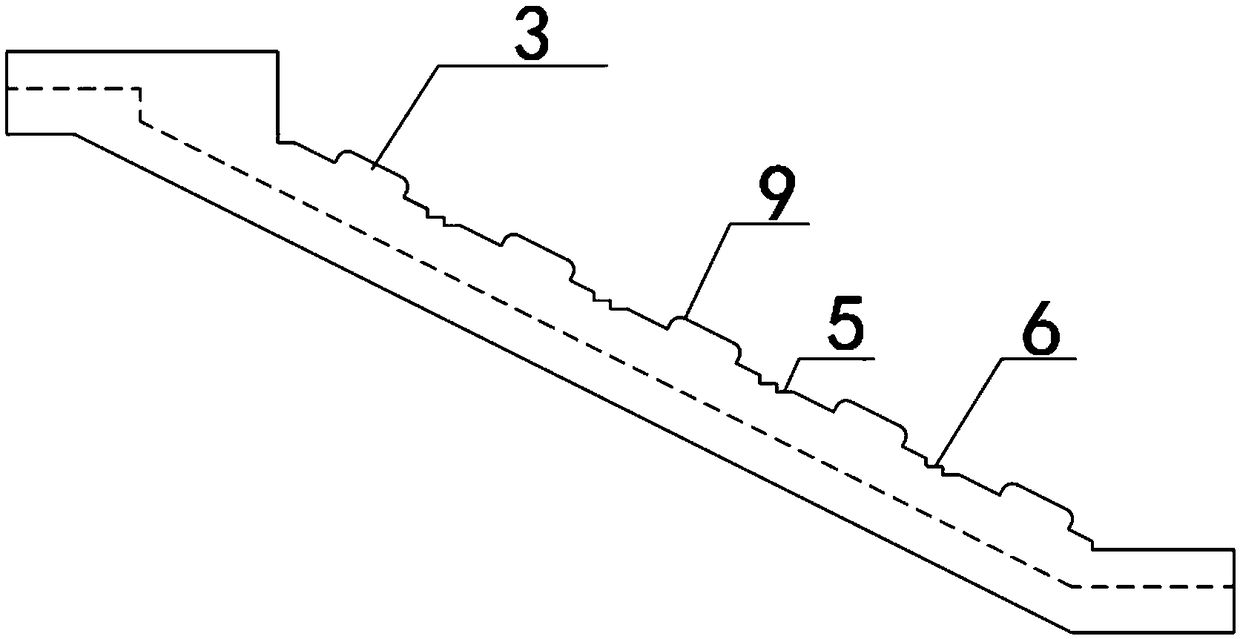

[0052] See figure 1 , figure 2 , Figure 4 , Figure 5 and Image 6 , a prefabricated assembled staircase provided by this embodiment, its composition includes: a stair base 1, a plurality of tread blocks 2, a high-performance building epoxy resin adhesive 11, a solar panel with a tempered glass shell, the described The stair base 1 is a beam-type stair base with a thin web, and there are prefabricated rectangular bosses 3, L-shaped recesses 5 and L-shaped recesses 6 on the stair base 1, which are used to connect with a pedal block; The rectangular notch 4, the horizontal L-shaped boss 7 and the vertical L-shaped boss 8 are equipped with a solar panel 12, a solar battery 14 and a cold light lamp panel 15.

[0053] When the prefabricated assembled staircase is installed, the tread block 2 is assembled on the stair floor 1 by hoisting, and the epoxy resin adhesive and the rectangular convex platform 3 and the rectangular notch 4 are used to match the structure, the L-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com