Sliding doors with reinforced core

A sliding door and core material technology, which is applied in the field of sliding doors and furniture, can solve the problems of shortened service life, small adjustment range, damage to sliding doors, etc., achieves convenient and fast production and assembly, improves connection strength, and reduces production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

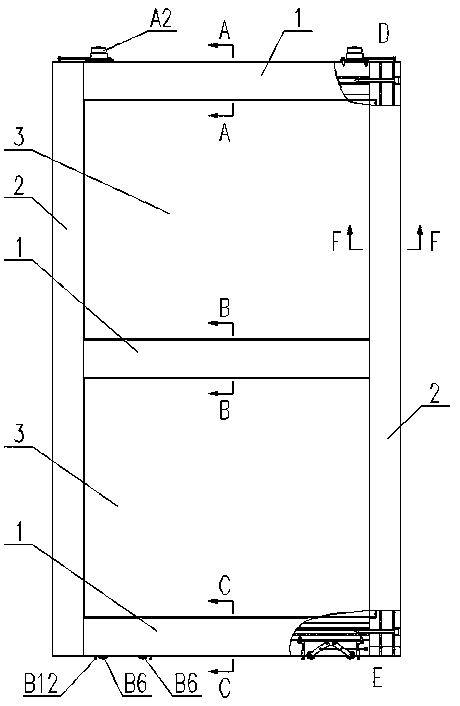

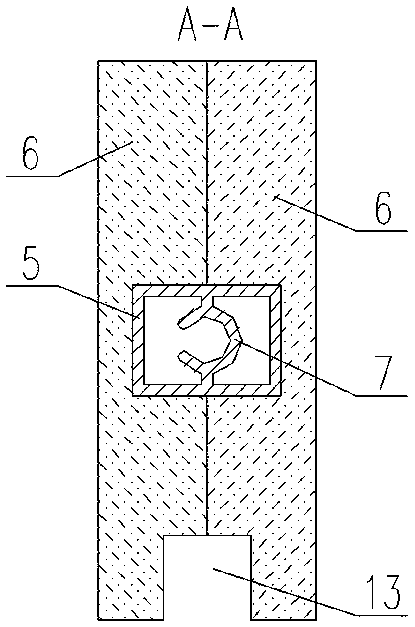

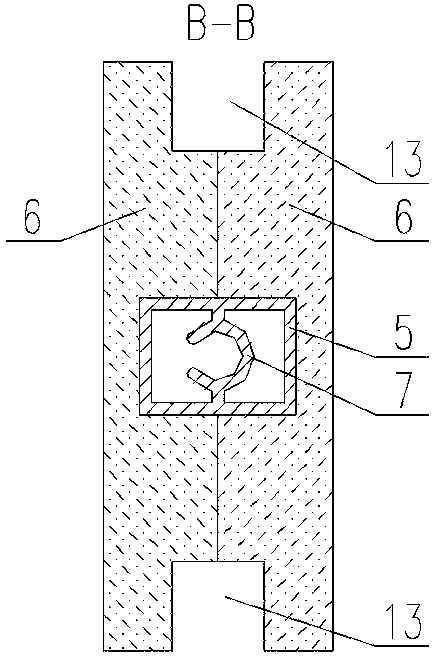

[0035] Depend on figure 1 As shown, the sliding door with reinforced core material includes a horizontal plate 1, a pair of vertical plates 2, a panel 3, locking screws 4, a pair of upper guide wheel mechanisms and a pair of lower pulley mechanisms, Depend on figure 2 , image 3 and Figure 4 As shown, the horizontal board 1 is composed of a first core material 5 and a pair of first solid wood boards 6, and the pair of first solid wood boards 6 are respectively provided with grooves corresponding to the first core material 5. , the paired first solid wood boards 6 are fixedly bonded together, the first core material 5 is fixedly clamped and bonded in the groove of the paired first solid wood boards 6, the cross section of the first core material 5 is square Frame shape, a central core material 7 with a non-closed circular cross-section is arranged inside the first core material 5 in the shape of a square frame. Depend on Figure 5 As shown, the paired vertical boards 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com