Fall-off detection method and system of exhaust sensor of variable frequency air conditioner

An exhaust gas sensor, inverter air conditioner technology, applied in heating and ventilation control systems, heating and ventilation safety systems, heating methods, etc., can solve the problem that the control system cannot detect the real temperature of the exhaust gas, cannot judge the sensor temperature probe, Destruction of copper tube strength and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

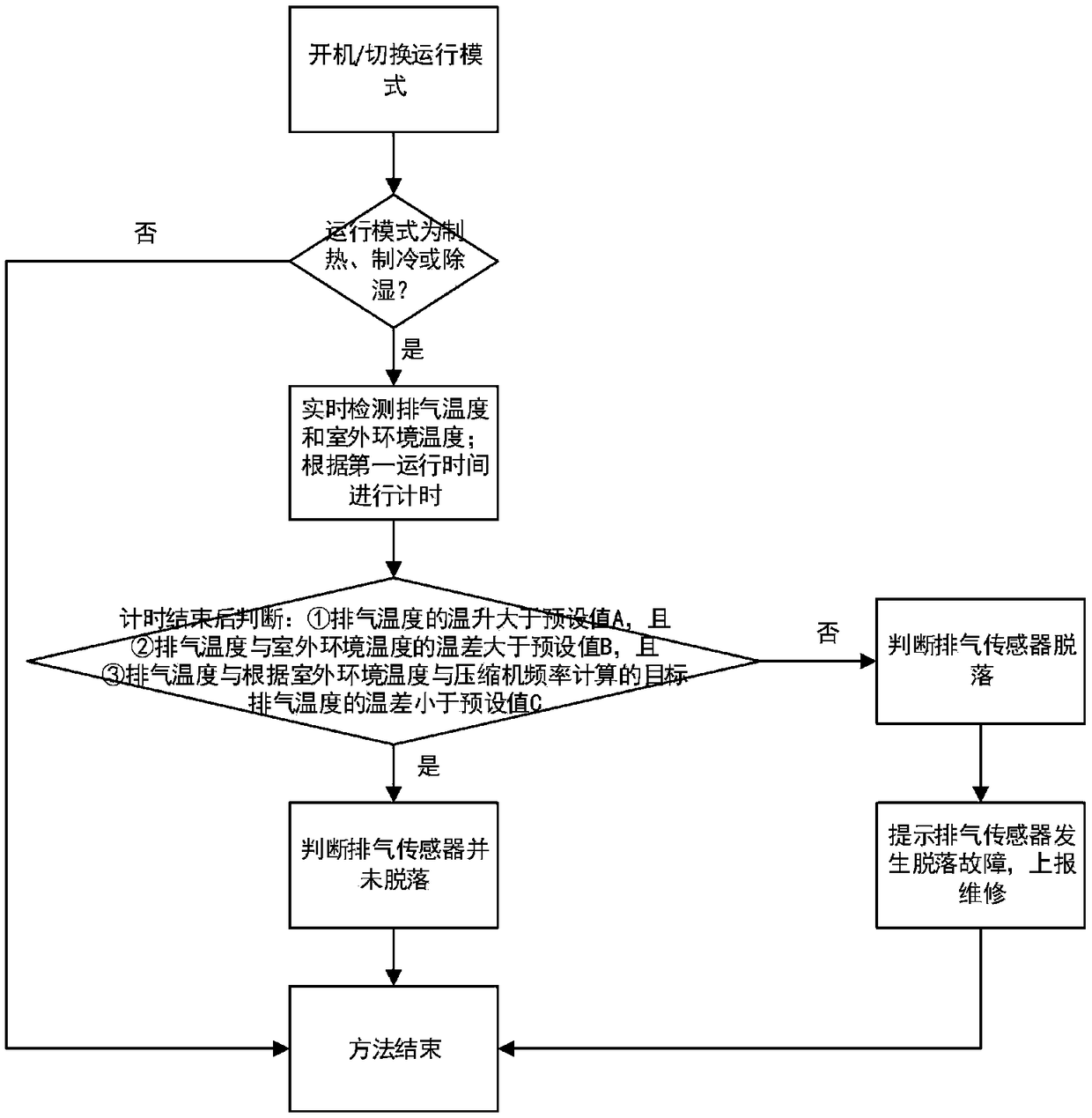

[0073] A detection method for the detachment of the exhaust sensor of an inverter air conditioner, such as figure 1 shown, including the following steps:

[0074] S100: The air conditioner judges the operation mode when the air conditioner is turned on or when the operation mode is switched. If the operation mode is heating mode, cooling mode or dehumidification mode, step S110 is executed. If the compressor is not started in the operation mode, the method is terminated;

[0075] S110: Timing is performed according to the preset first running time, and the exhaust temperature and outdoor ambient temperature are collected in real time; when the timing reaches the first running time, it is judged: ①Whether the temperature rise of the exhaust gas temperature is greater than the preset value A, ② Whether the temperature difference between the exhaust gas temperature and the outdoor ambient temperature is greater than the preset value B, ③Whether the temperature difference between ...

Embodiment 2

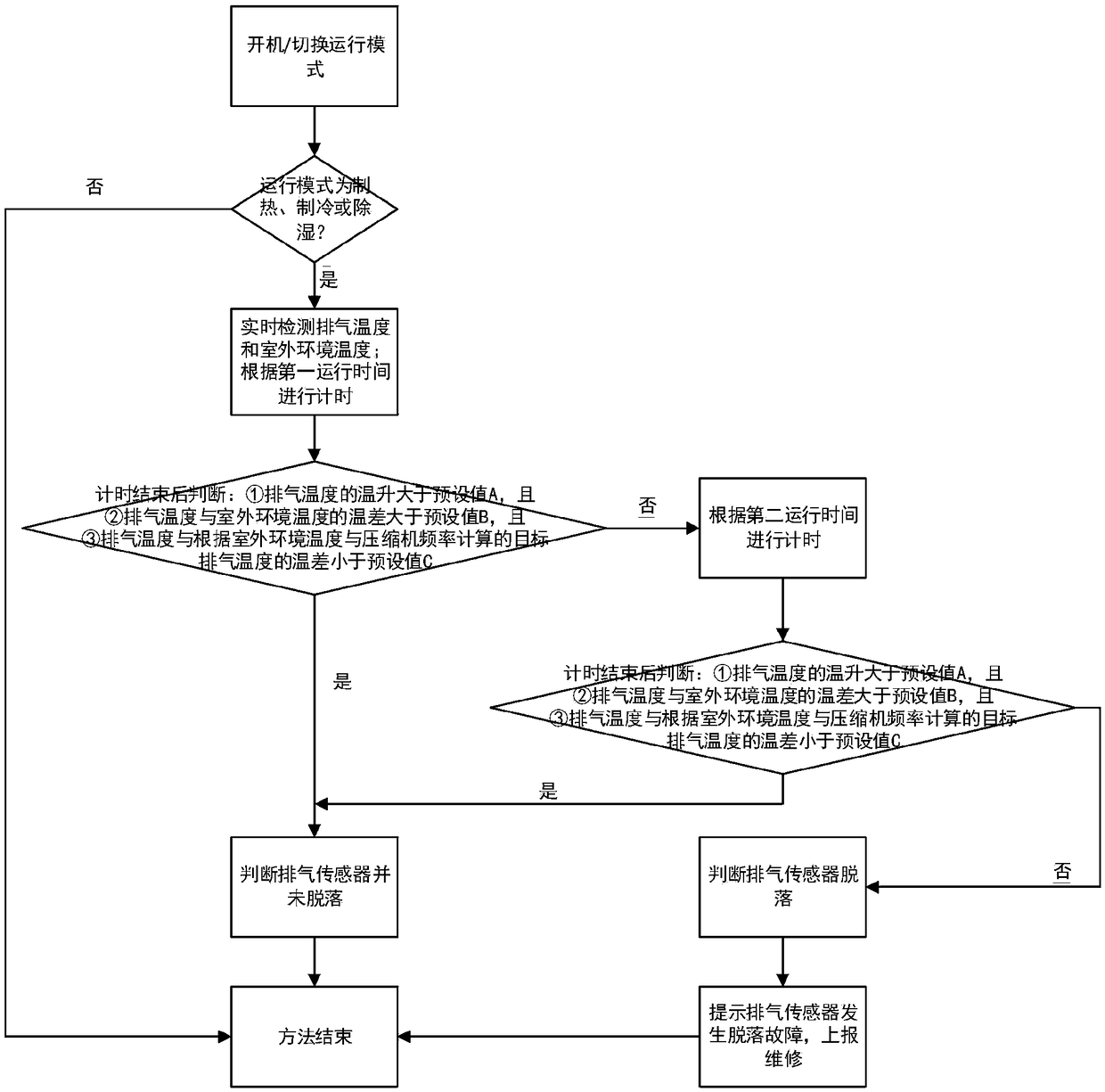

[0081] A detection method for the detachment of the exhaust sensor of an inverter air conditioner, such as figure 2 shown, including the following steps:

[0082] S100: The air conditioner judges the operation mode when the air conditioner is turned on or when the operation mode is switched. If the operation mode is heating mode, cooling mode or dehumidification mode, step S110 is executed. If the compressor is not started in the operation mode, the method is terminated;

[0083] S110: Timing is performed according to the preset first running time, and the exhaust temperature and outdoor ambient temperature are collected in real time; when the timing reaches the first running time, it is judged: ①Whether the temperature rise of the exhaust gas temperature is greater than the preset value A, ② Whether the temperature difference between the exhaust gas temperature and the outdoor ambient temperature is greater than the preset value B, ③Whether the temperature difference between...

Embodiment 3

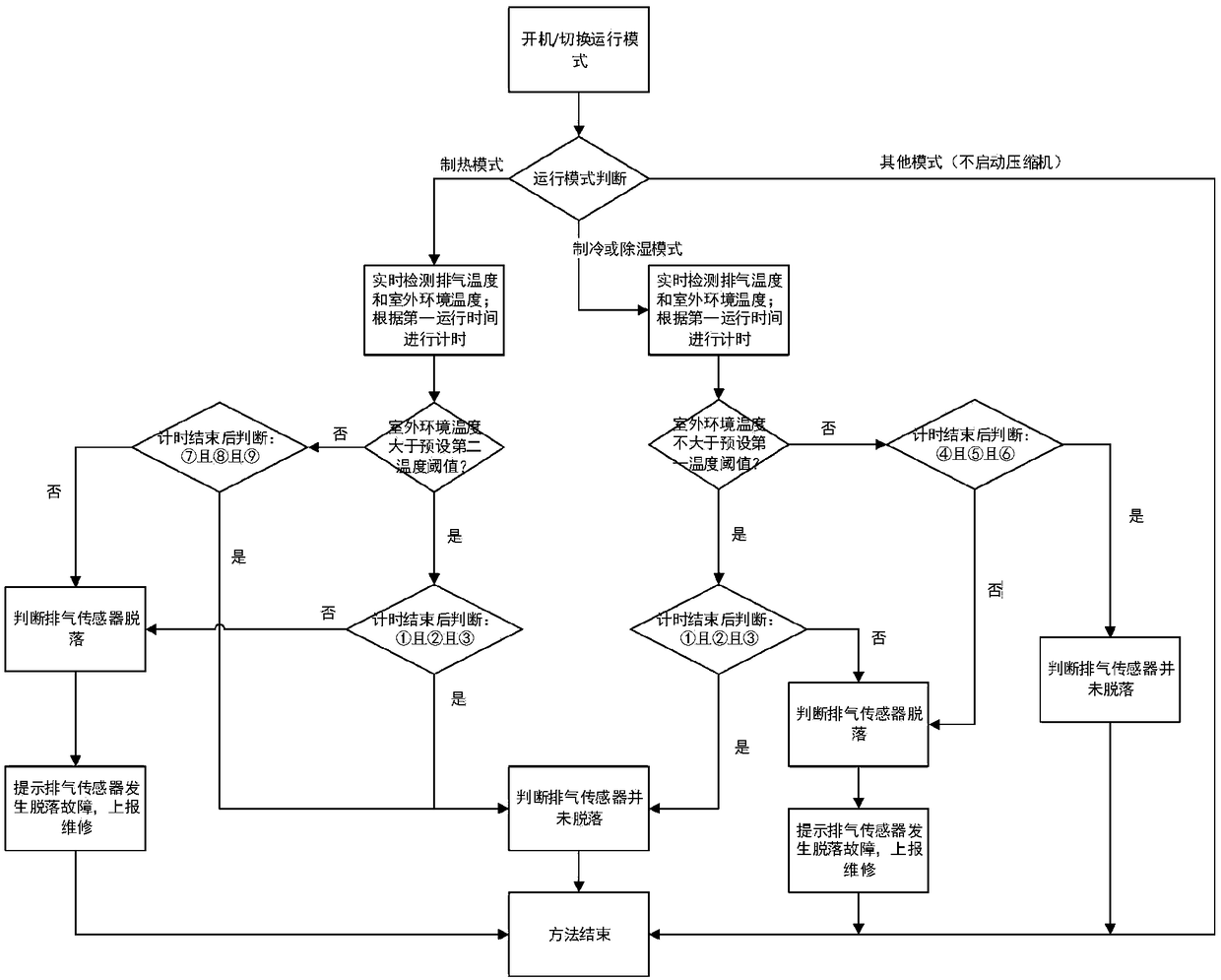

[0089] A detection method for the detachment of the exhaust sensor of an inverter air conditioner, such as image 3 shown, including the following steps:

[0090] S100: The air conditioner judges the operation mode when it is turned on or when the operation mode is switched. If the operation mode is cooling mode or dehumidification mode, execute step S110; if the operation mode is heating mode, execute step S120; If activated, the method terminates;

[0091] S110: Timing is performed according to the preset first running time, and the exhaust gas temperature and the outdoor ambient temperature are collected in real time; when the timing reaches the first running time, the outdoor ambient temperature is judged, if the outdoor ambient temperature is not greater than the preset first temperature threshold, then execute step S111, otherwise execute step S112;

[0092] S111: Judgment: ①Whether the temperature rise of the exhaust gas temperature is greater than the preset value A,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com