Detecting method, device and equipment for temperature of power module of converter and medium

A technology of a power module and a detection method, applied in the field of converters, can solve the problems of low detection accuracy and inapplicability, and achieve the effects of accurate calculation results, strong practicability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

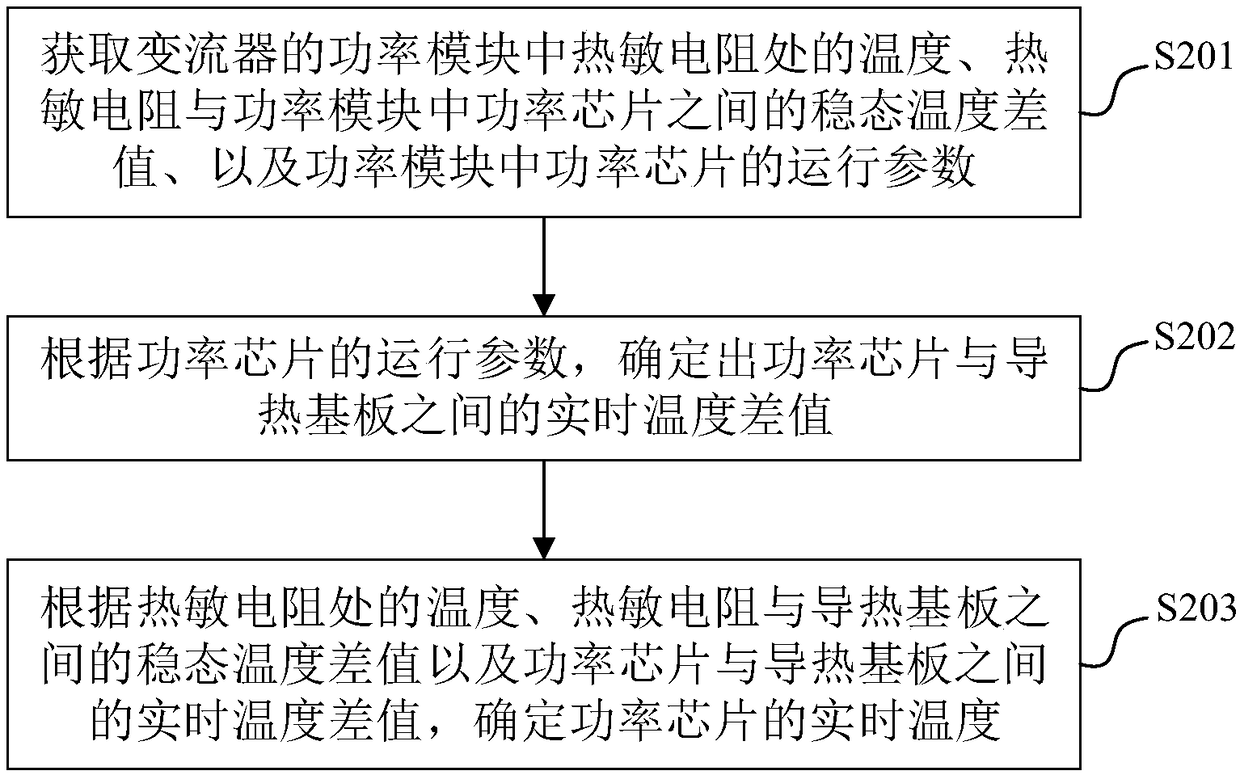

[0049]Embodiment 1 of the present application provides a method for detecting the temperature of a power module of a converter. The schematic flow chart of the detection method is shown in figure 2 shown, including:

[0050] S201. Obtain the temperature at the thermistor in the power module of the converter, the steady-state temperature difference between the thermistor and the power chip in the power module, and the operating parameters of the power chip in the power module.

[0051] Optionally, the operating parameters of the power chip include: average temperature of the power chip, output current, switching times, turn-on duty cycle, and thermal impedance parameters between the power chip and the heat-conducting substrate. The thermistor may be an NTC (Negative Temperature Coefficient, negative temperature coefficient) resistor, so as to reduce temperature fluctuations and improve response speed to temperature changes.

[0052] S202. Determine the real-time temperature d...

Embodiment 2

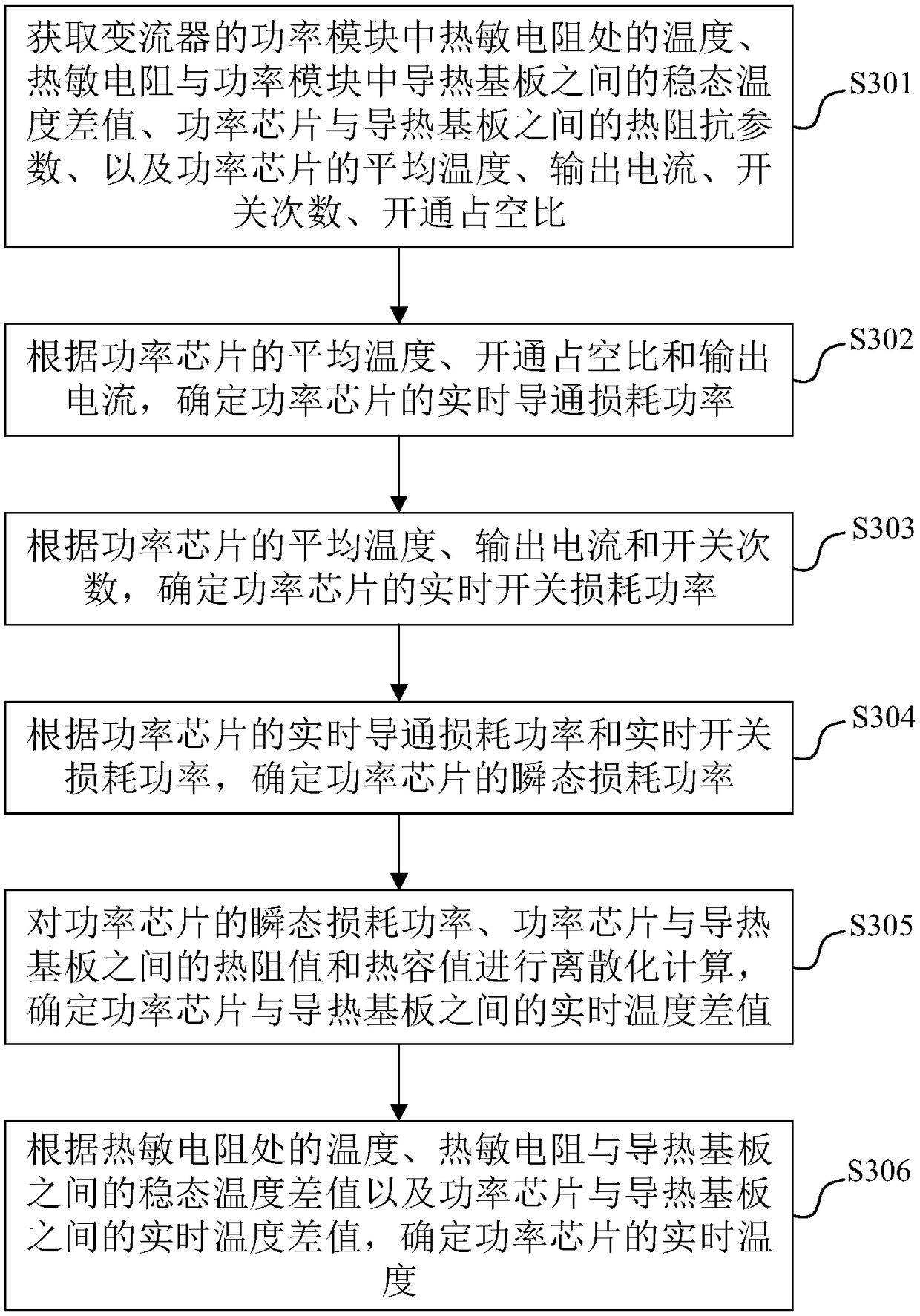

[0068] On the basis of Embodiment 1, another possible implementation provided by Embodiment 2 of this application, such as image 3 As shown, the method includes:

[0069] S301. Obtain the temperature at the thermistor in the power module of the converter, the steady-state temperature difference between the thermistor and the heat conduction substrate in the power module, the thermal impedance parameter between the power chip and the heat conduction substrate, and the power chip The average temperature, output current, switching times, and on-duty cycle of the

[0070] Optionally, the temperature at the thermistor can be detected and determined in advance, and the thermistor can be an NTC resistor, so as to reduce temperature fluctuations and increase the response speed to temperature changes.

[0071] Optionally, the steady-state temperature difference between the thermistor and the thermally conductive substrate can be predetermined by:

[0072] According to the pre-detect...

Embodiment 3

[0143] On the basis of Embodiment 1 or 2, another possible implementation provided by Embodiment 3 of this application, such as Image 6 As shown, the method includes:

[0144] S601. Obtain the temperature at the thermistor in the power module of the converter, the steady-state temperature difference between the thermistor and the heat conduction substrate in the power module, and the operating parameters of the power chip in the power module.

[0145] For the range covered by the operating parameters and the type of the thermistor, reference may be made to the relevant content of Embodiment 1, and details are not repeated here.

[0146] Optionally, for the calculation principle of the steady-state temperature difference between the thermistor and the heat-conducting substrate, reference may be made to the related content of Embodiment 2, which will not be repeated here.

[0147] S602. Determine the real-time temperature difference between the power chip and the heat conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com