Portable and detachable pillar stability and bottom plate load transfer simulation device

A technology of load transfer and simulation device, which is used in measuring devices, using stable tension/pressure to test the strength and strength characteristics of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

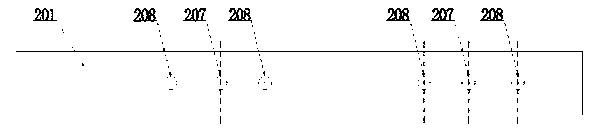

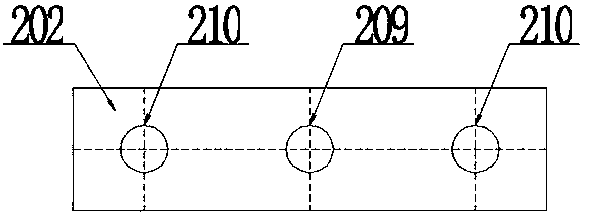

[0029] This embodiment provides a portable detachable pillar stability and floor load transfer simulation device, such as figure 1 As shown, it includes a top pressure loading part, a side pressure loading part, a bottom support part and a baffle plate; The pressure bearing plate 104 and two upper pressure plates 105; the number of side pressure loading parts is two, which are arranged equidistantly on both sides of the pressure head 102, including side beams 201, side pressure bearing plates 202, side pressure plates 203, and side pressure applying bolts 204, a screw rod 205 and a spring 206; the bottom support portion includes a bottom beam 301 opposite to the top beam 101; as figure 2 As shown, the middle part of the top beam 101 is provided with a pressure head layout hole 106; the upper pressure plate 104 is located between the two upper pressure plates 105, and the total area of the upper pressure plate 104 and the two upper pressure plates 105 is the same as that of ...

Embodiment 2

[0037] This embodiment provides specific dimensions based on the portable and detachable pillar stability and floor load transfer simulation device described in Embodiment 1.

[0038] Such as figure 2 As shown, the length of the top beam 101 is 500mm, the diameter of the pressure head arrangement hole 106 at the waist is 55mm, and a screw hole with a diameter of 11~12mm is drilled at the waist at a distance of 10mm from both ends without tapping, which can penetrate M10 bolts .

[0039] The indenter 102 is cylindrical, made of No. 45 steel, with a diameter of 50mm and a height of 120mm.

[0040] The upper pressure plate 104 is 5mm thick, 80mm wide, and has five sizes of 50mm, 75mm, 100mm, 125mm and 150mm in length; The total length of the plate 104 and the two upper platens 105 is always 350 mm, and the distance from the top beam 101 is 50 mm.

[0041] The length of side beam 201 is 500mm, such as image 3 As shown, the waist is provided with two side beam threaded holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com