High wave-band space travelling wave tube PPM structure optimization designing method

An optimized design, traveling wave tube technology, applied in transit-time electron tubes, discharge tubes, measurement/testing in the manufacturing process, etc. and other problems, to achieve the effects of improving the asymmetry of the magnetic field, improving the symmetry of the magnetic field, and reducing the electron injection wave.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Taking the 10-period PPM structure with a period of 4mm as an example, the technical solution of the present invention will be further described in detail below.

[0025] (1) Use the Microwave Tube Set Simulator (MTSS) developed by UESTC to simulate the PPM structure and the PPM structure with magnetic ring offset to obtain its magnetic field distribution;

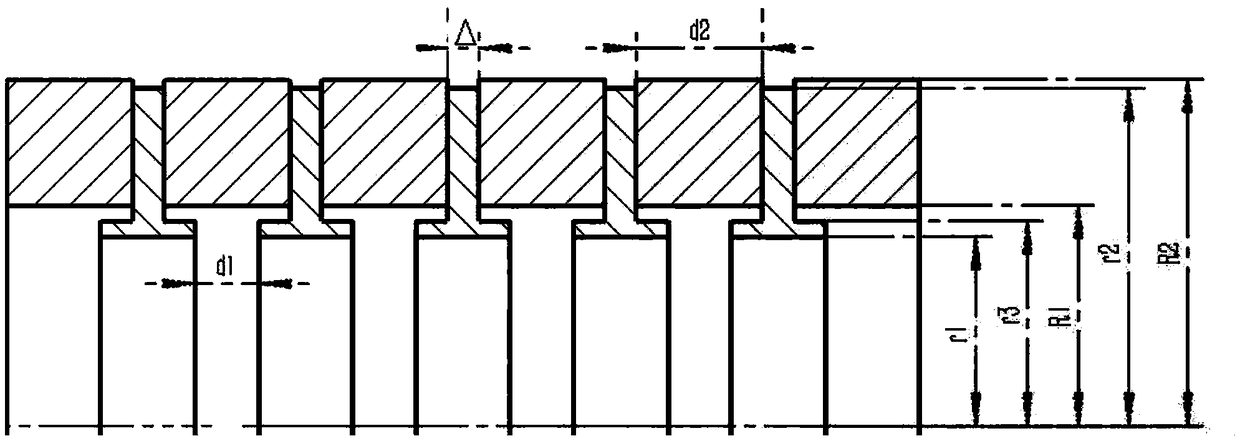

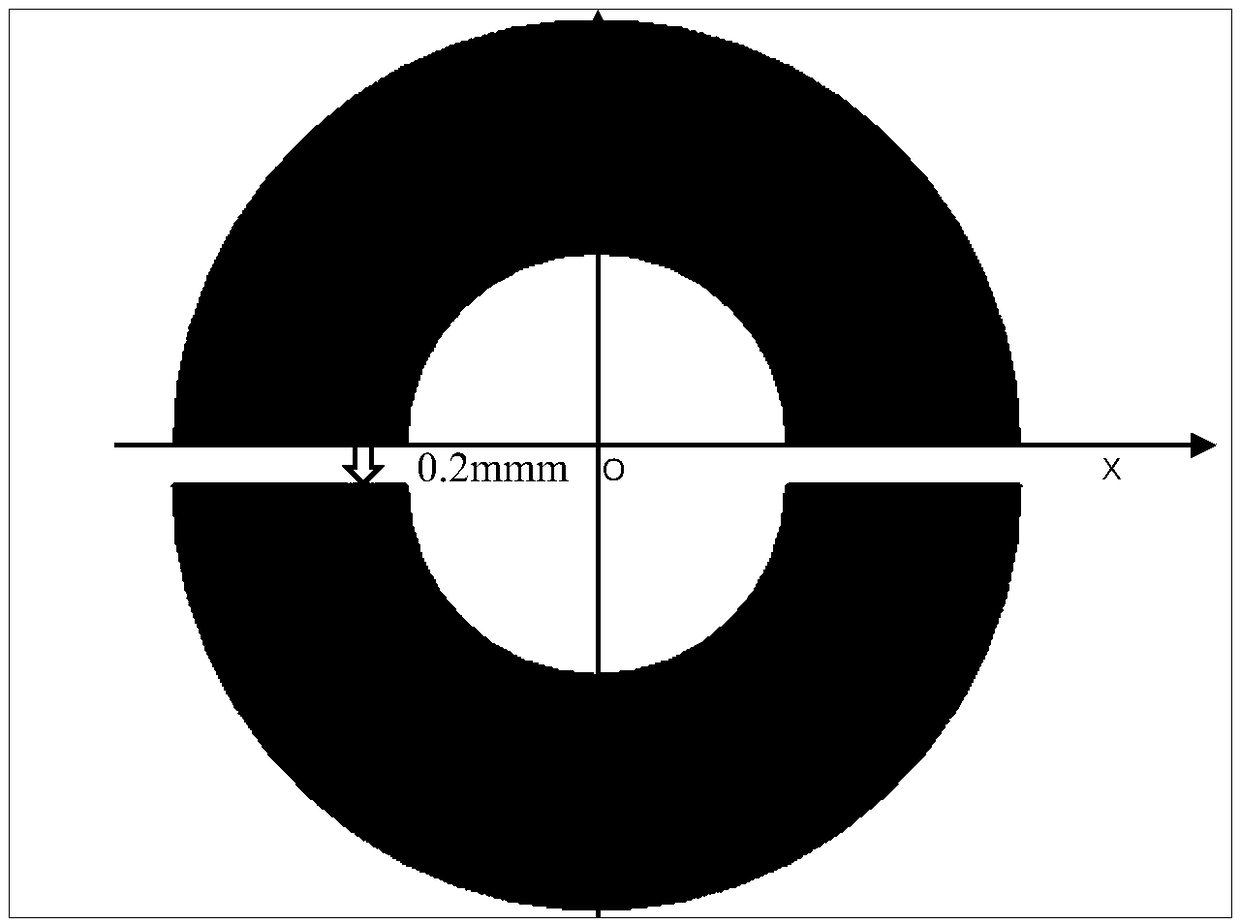

[0026] The PPM structure adopted by the embodiment, such as figure 1 As shown, the circular magnetic rings and pole pieces are arranged alternately, and the material of the magnetic rings is SmCo 28 , The pole shoe material is pure iron _1008. The PPM structure of magnetic ring offset, such as figure 2 As shown, the lower half of the third magnetic ring is offset to the negative direction of the y-axis by 0.2mm, such as image 3 As shown, the upper half of the fourth magnetic ring is offset by 0.1mm to the positive direction of the y-axis, and the offset of the lower half is offset to the negative direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com