Method for alcoholizing and fermenting fresh and sweet type flue-cured tobacco leaves using biotechnology

A biotechnology, sweet and fragrant technology, applied in the field of light industrial tobacco, can solve the problems of reducing the time of alcoholization and fermentation, and achieve the effect of increasing the added value of science and technology, improving the quality of tobacco, and shortening the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

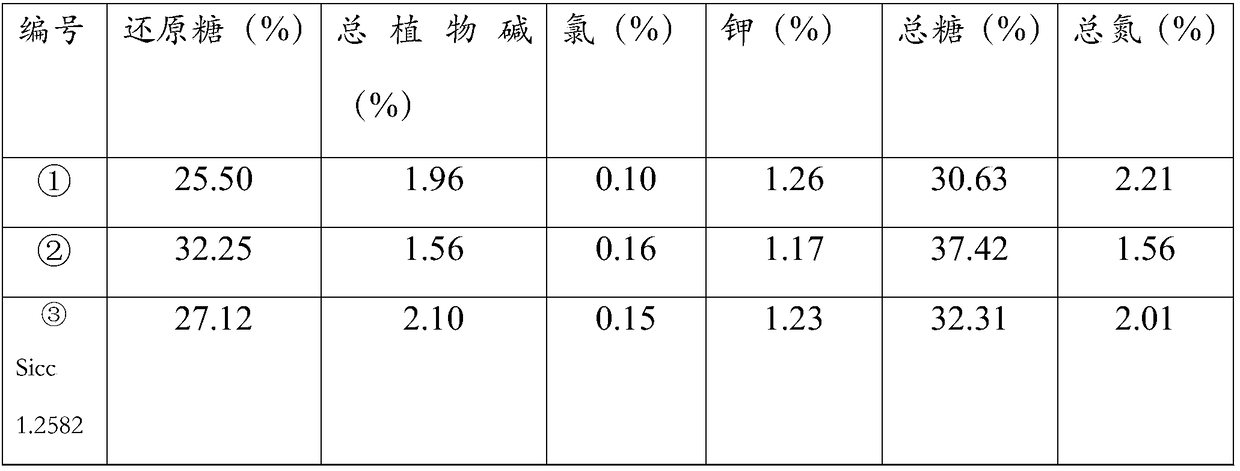

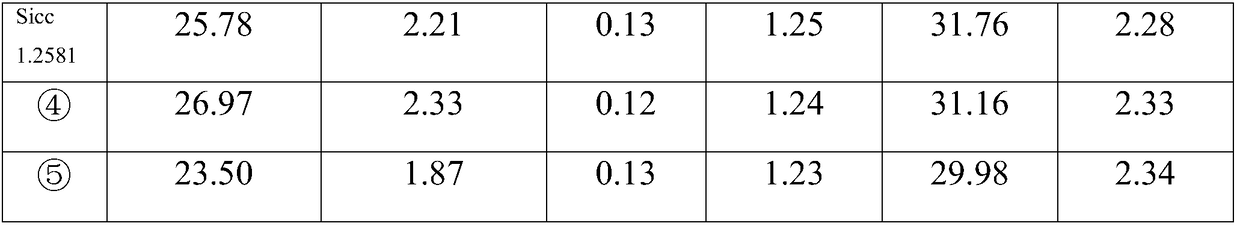

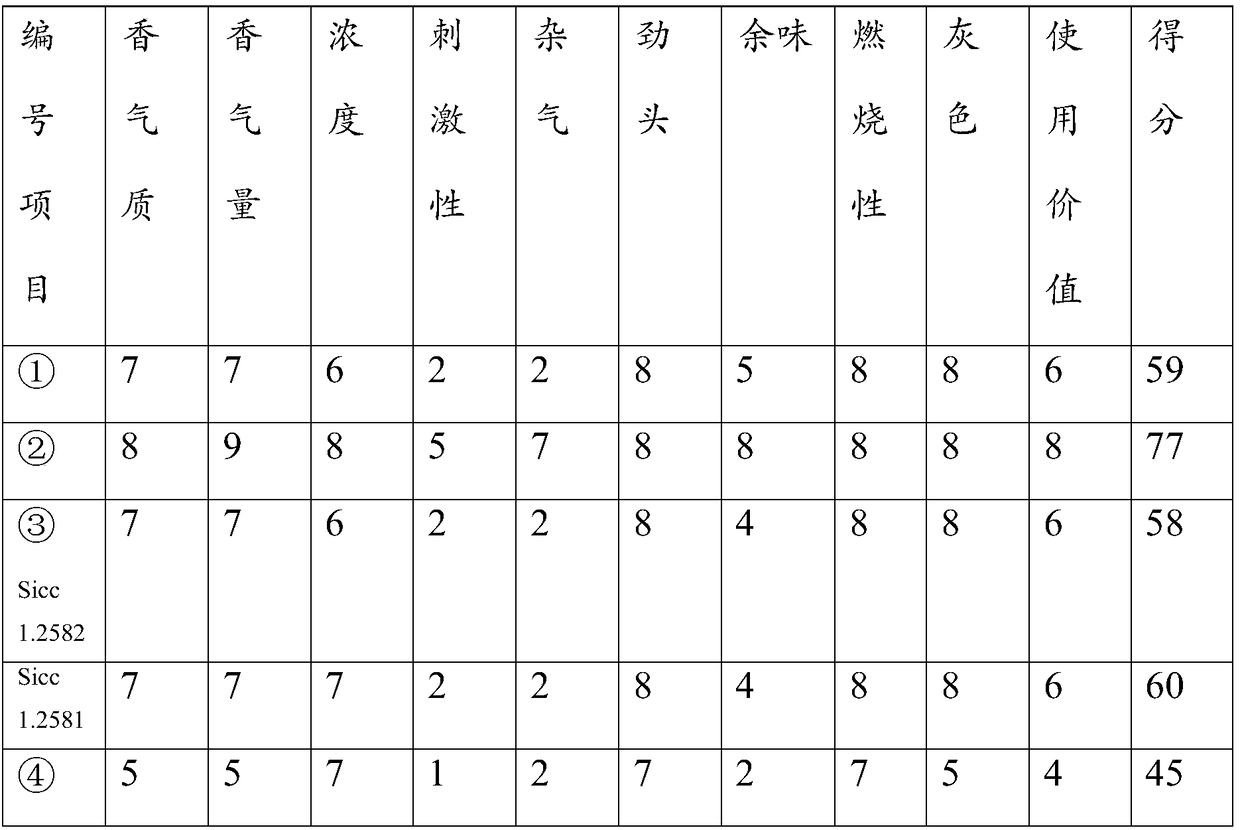

[0036] Panzhihua, Yun 85, C2F, "Sweet and fragrant" flue-cured tobacco biotechnology alcohol fermentation

[0037] 1.1 Firstly, the strain No. sicc 1.2583 tobacco leaf aroma-enhancing strain (Enterobacter hormaechei strain SCEH020042) purchased from the Sichuan Provincial Microbial Resource Platform Strain Collection Center was used as the tobacco leaf alcoholization fermentation aroma-enhancing bacterial agent;

[0038] 1.2 Take a ring of tobacco leaf aroma-enhancing and quality-enhancing strains and culture them in the primary seed solution (LB medium, pH=7.4) at a temperature of 37°C and a rotating shaker at a rotational speed of 220r / min for 24 hours.

[0039] 1.3 Inoculate the first-level seed solution into the second-level seed solution (LB tobacco juice medium) at a temperature of 37°C with a rotation speed of 220r / min on a rotary shaker at a 10% inoculation amount, and cultivate for 24 hours, OD 600 Greater than 1.

[0040] 1.4 Drying the "sweet and fragrant" flue-cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com