A photocatalytic and biological bed compound vocs purification equipment

A kind of purification equipment and photocatalysis technology, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of low purification efficiency, no consideration of changes in gas volume, and unsuitable VOCs gas purification, etc., to achieve improved The effect of purification rate, efficiency improvement and area increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

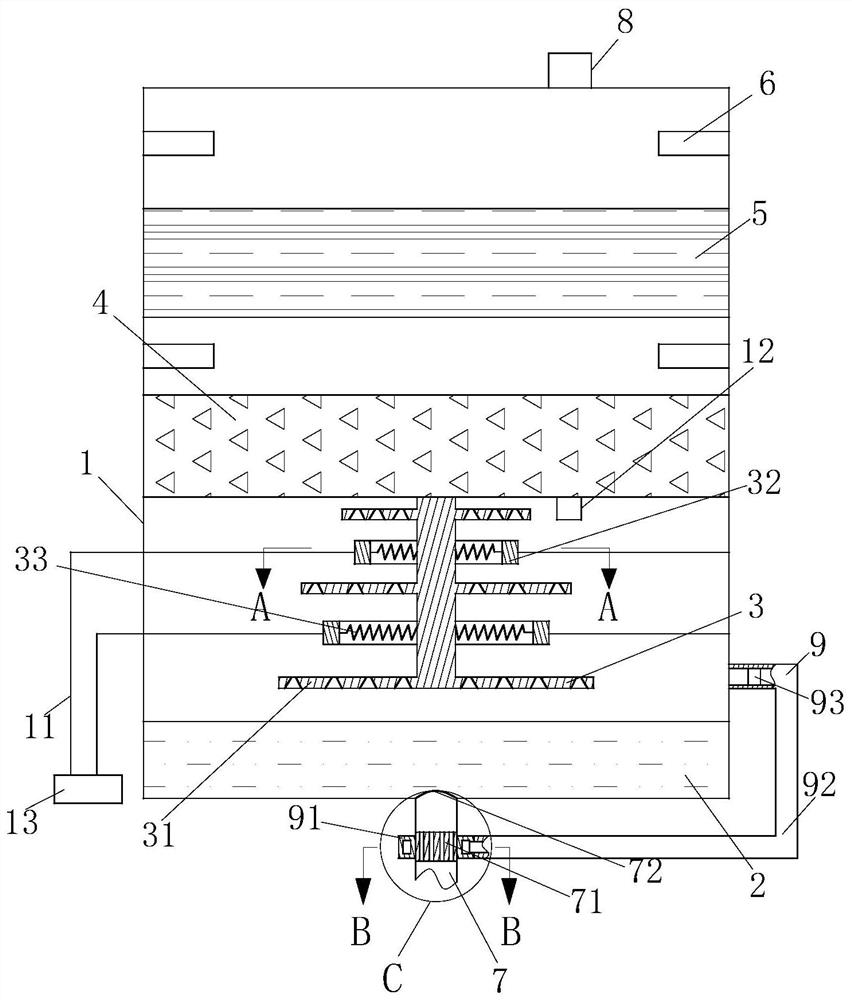

[0022] use Figure 1-Figure 4 The structure of the photocatalytic and biological bed composite VOCs purification equipment according to one embodiment of the present invention is described as follows.

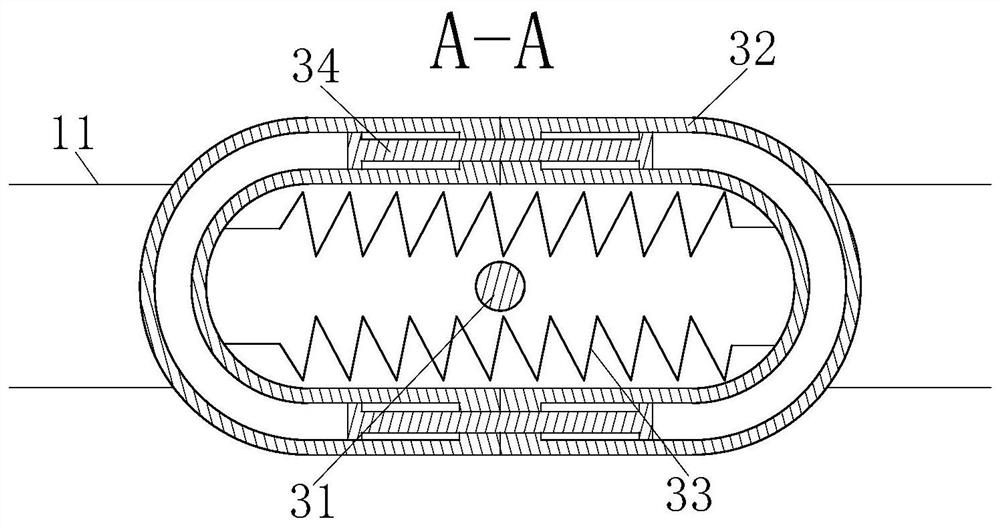

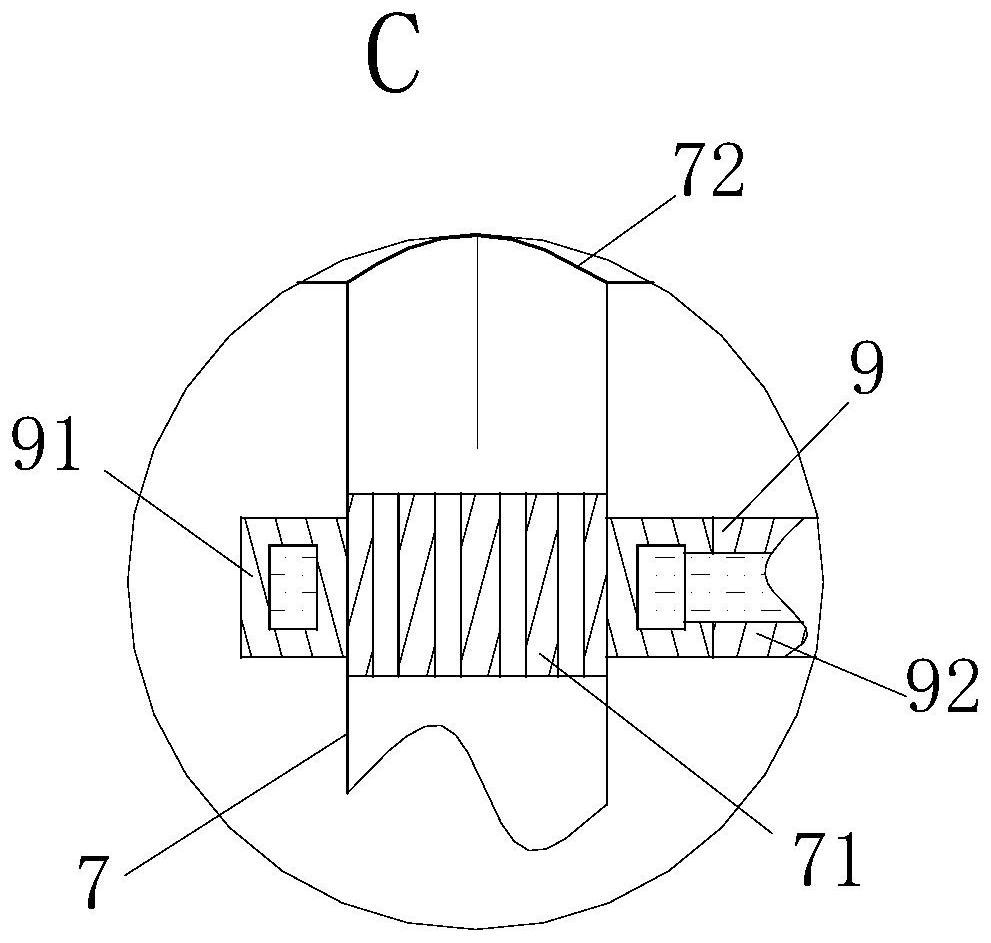

[0023] Such as figure 1As shown, a photocatalytic and biological bed composite VOCs purification device according to the present invention includes a reaction chamber 1, an elution pool 2, a photocatalytic device 3, a biodegradation layer 4, a biofiltration layer 5, a nozzle 6, and a Gas pipeline 7, gas outlet 8 and feedback adjustment device 9; The elution pool 2 is located in the reaction chamber 1, and the elution pool 2 is located at the bottom of the reaction chamber 1, and the elution pool 2 is used to oxidize the VOCs gas, so as to realize the The first layer of VOCs gas treatment; the photocatalytic device 3 is located in the reaction chamber 1, the photocatalytic device 3 is located above the eluting pool 2, and the photocatalytic device 3 is used to catalyze the degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com