Batch feeding and stirring method for concrete and device

A stirring method and technology of a stirring device, which are applied in the direction of a control device, etc., can solve the problems of large load of the stirring host, high equipment wear, and waste of resources, and achieve the effects of reducing boring machines, lightening loads, and reducing equipment wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

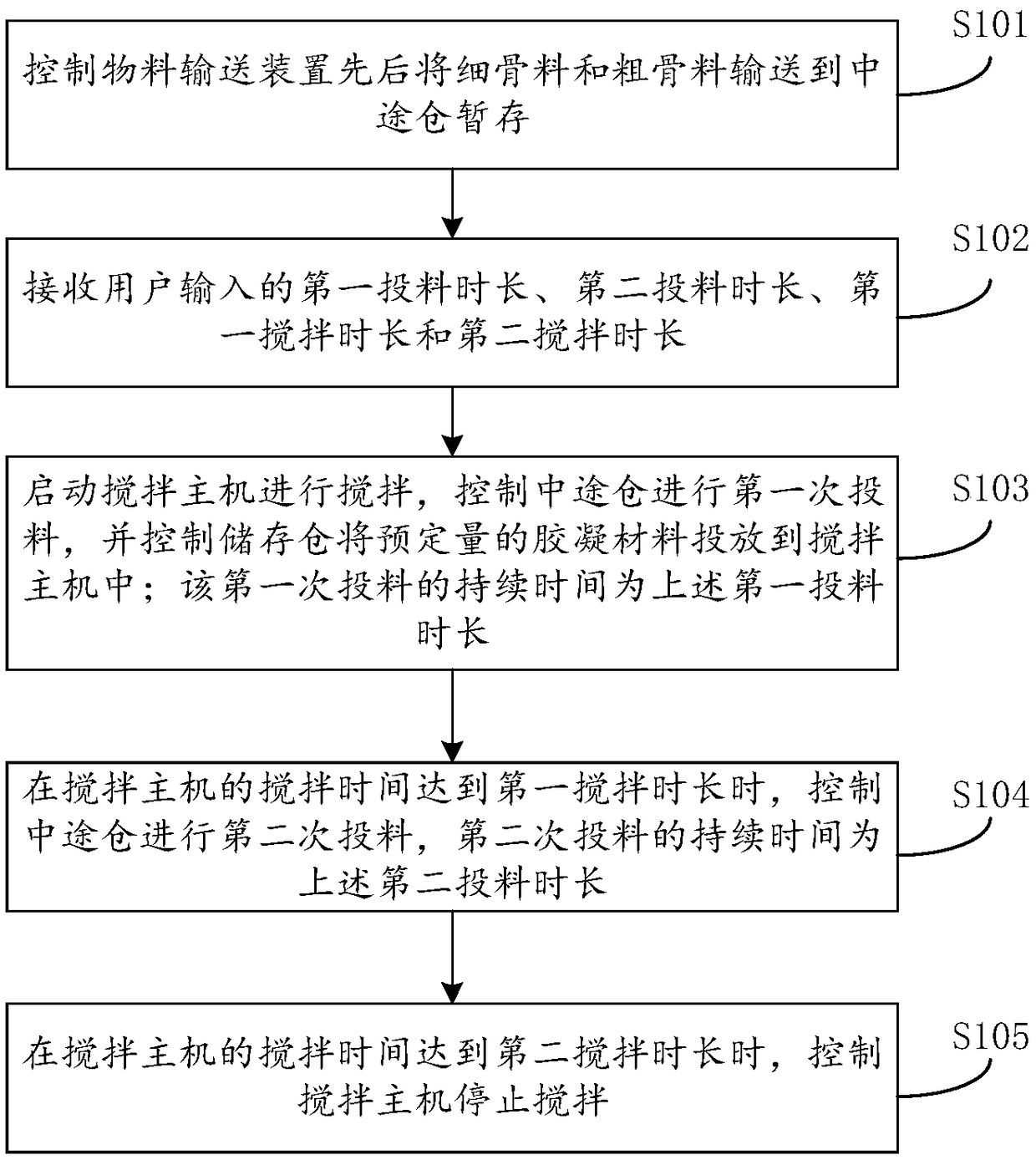

[0031] Such as figure 1 As shown, it is a schematic flow chart of a concrete feeding and mixing method provided by an embodiment of the present invention. This method is applied to a mixing station, and the figure 1 Visible, this method comprises the following steps:

[0032] Step S101: Control the material conveying device to successively convey the fine aggregate and the coarse aggregate to the intermediate warehouse for temporary storage.

[0033] Here, the conveying device refers to a material handling machine that continuously conveys materials on a certain line, also known as an assembly line. The conveying line can carry out horizontal, inclined and vertical conveying, and can also form a space conveying line, and the conveying line is generally fixed. In traditional mixing plants, flat belts and inclined belts are usually used to convey materials. Among them, fine aggregate is an aggregate with a relatively small diameter. It is a granular loose material that acts a...

Embodiment 2

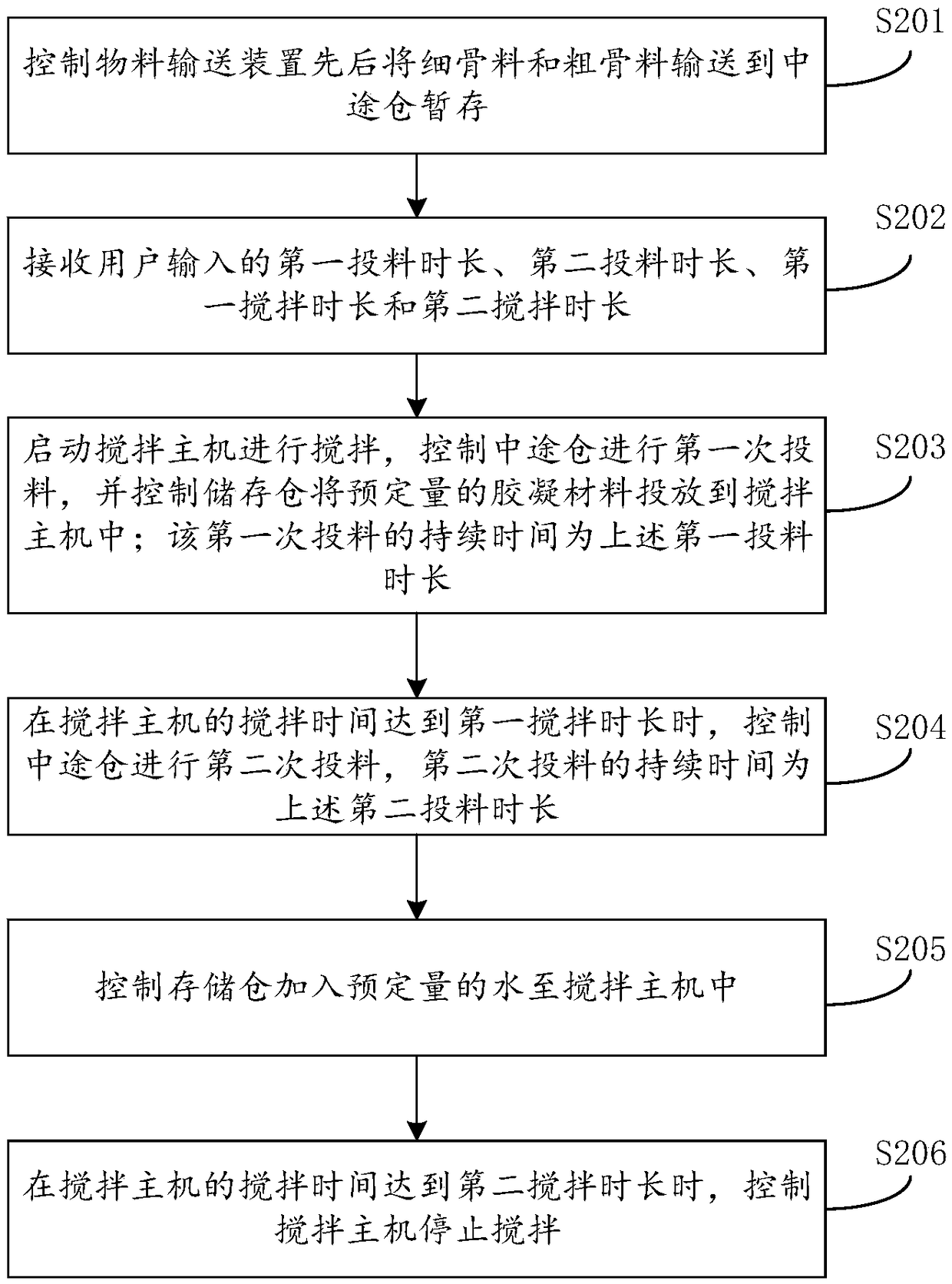

[0048] The embodiment of the present invention aims at the difference in the delivery order of fine aggregate and coarse aggregate, and introduces a feasible intermediate warehouse structure, wherein, the intermediate warehouse includes at least two compartments, and the fine aggregate can be placed The material and coarse aggregate are transported to the two compartments separately and stored independently. These two bins can have their own independent bin doors, which are controlled by the control system. When feeding for the first time, the door of the bin storing fine aggregate is opened for the first feeding, and for the second feeding. , then control to open the door of the cell where the coarse aggregate is stored. In addition, these two compartments can also share a compartment door, when the fine aggregate is put into the mixing machine, the coarse aggregate is not unloaded, and when the coarse aggregate is put in, the fine aggregate is not unloaded.

[0049] The con...

Embodiment 3

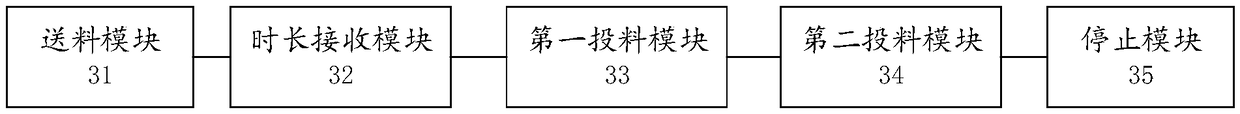

[0051] Embodiments of the present invention also provide a concrete feeding and mixing device, such as image 3 As shown, the device includes a sequentially connected feeding module 31, a duration receiving module 32, a first feeding module 33, a second feeding module 34 and a stop module 35, wherein the functions of each module are as follows:

[0052] The feeding module 31 is used to control the material conveying device to successively convey the fine aggregate and coarse aggregate to the intermediate warehouse for temporary storage;

[0053] The duration receiving module 32 is configured to receive the first feeding duration, the second feeding duration, the first stirring duration and the second stirring duration input by the user;

[0054] The first feeding module 33 is used to start the mixing main engine to stir, control the intermediate warehouse to perform the first feeding, and control the storage warehouse to put a predetermined amount of gelling material into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com