Surface layer for automotive trim and preparation method thereof

A technology for automobile interior decoration and automobile interior decoration panel, which is applied to the surface layer for automobile interior decoration and its preparation field, can solve the problems of heavy odor, pollute the environment, damage health, etc., and achieve the effect of excellent odor absorption performance and air purification performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

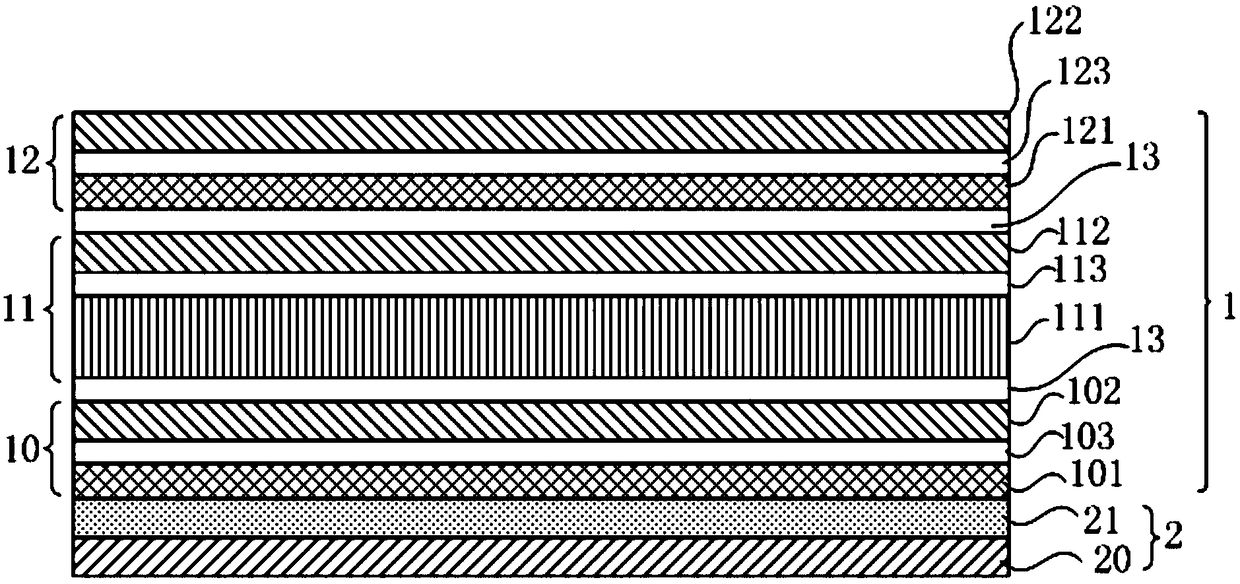

[0029] The specific implementation of the surface layer for automobile interior decoration provided by the present invention and the preparation method thereof will be described in detail below in conjunction with the accompanying drawings.

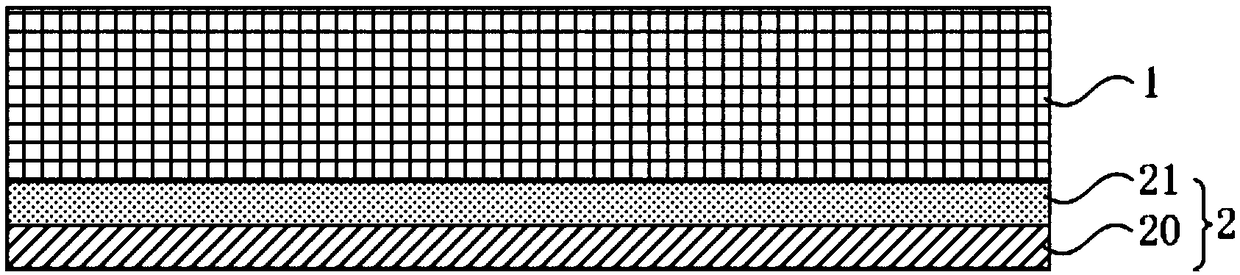

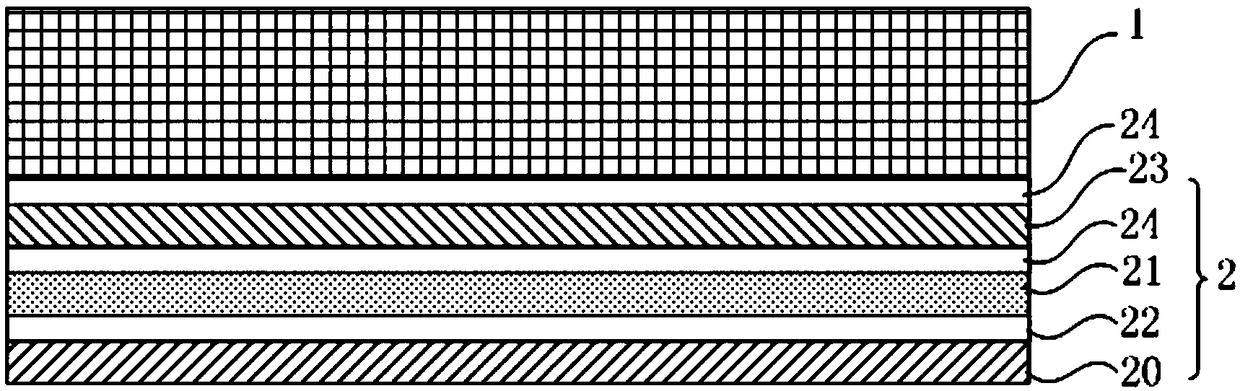

[0030] figure 1 It is a structural schematic diagram of the first embodiment of the surface layer for automobile interior decoration of the present invention. see figure 1 , The surface layer for automobile interior decoration of the present invention includes a bottom layer 1 and an interior decoration layer 2 .

[0031] The bottom layer 1 is connected with an automobile interior panel (not shown in the drawings). The interior decoration layer 2 is placed on the bottom layer 1, that is, the interior decoration layer 2 is an exposed decoration layer.

[0032] The interior trim layer 2 has a non-woven fabric layer 20 and a carbon cloth adsorption layer 21 . The non-woven fabric layer 20 is exposed to the air, that is, the non-woven fab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com