Coal chemical heavy oil sewage treatment technology

A technology for sewage treatment and sewage treatment system, which is applied in water/sewage treatment, biological water/sewage treatment, heating water/sewage treatment, etc. It can solve the problems of high power consumption, high cost and substandard sewage, and save energy. The effect of consumption, tight connection and sufficient settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

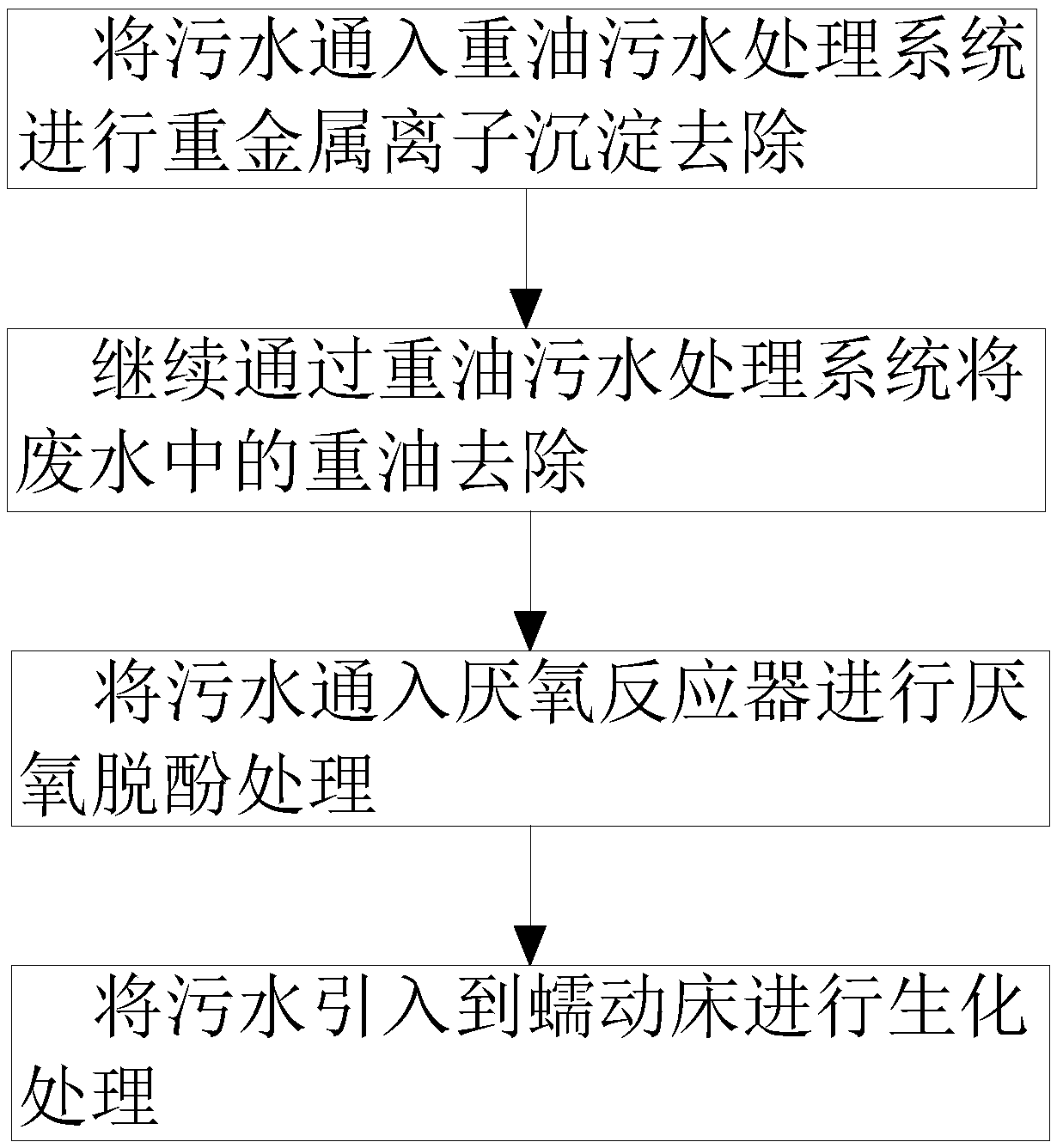

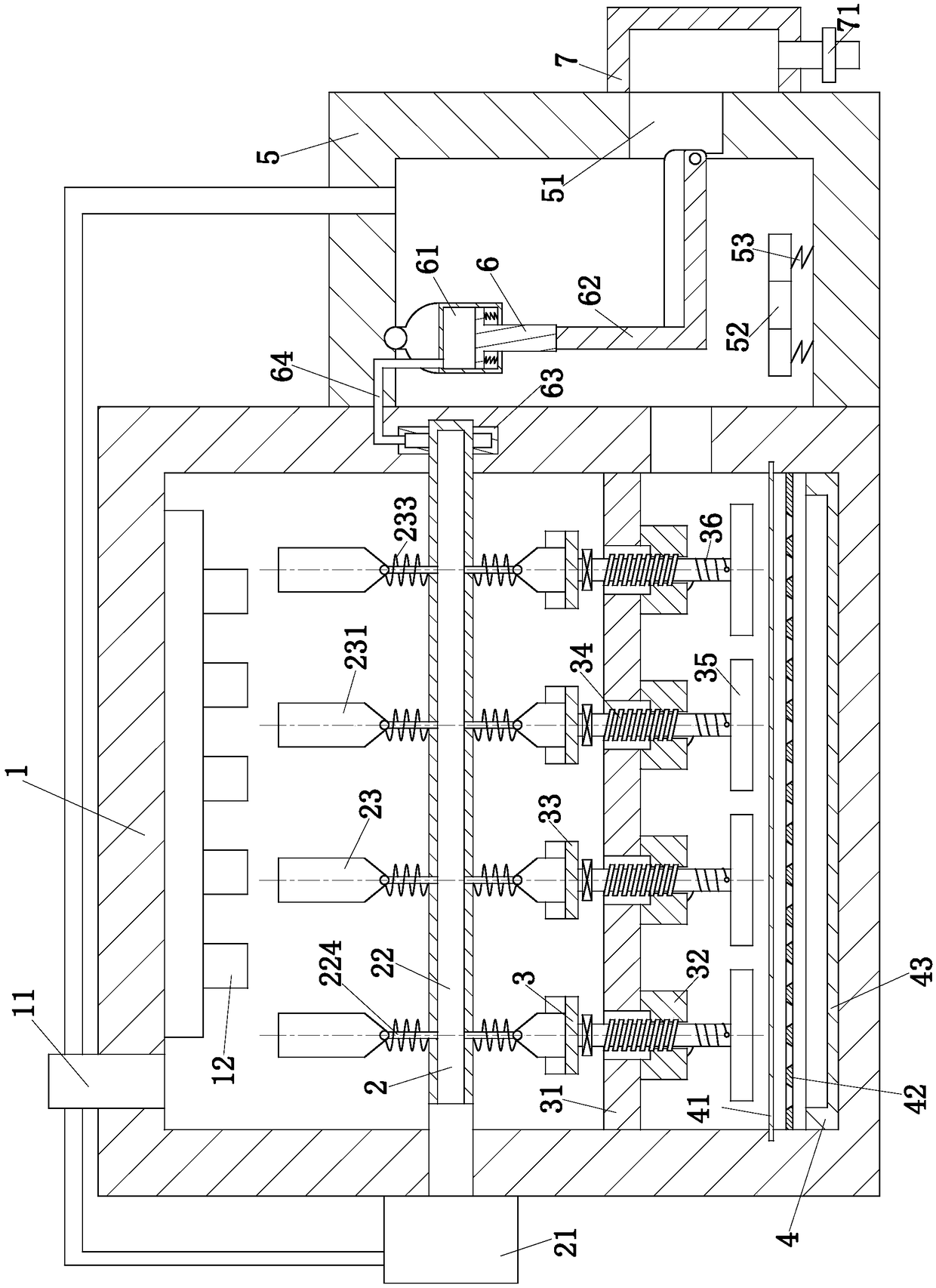

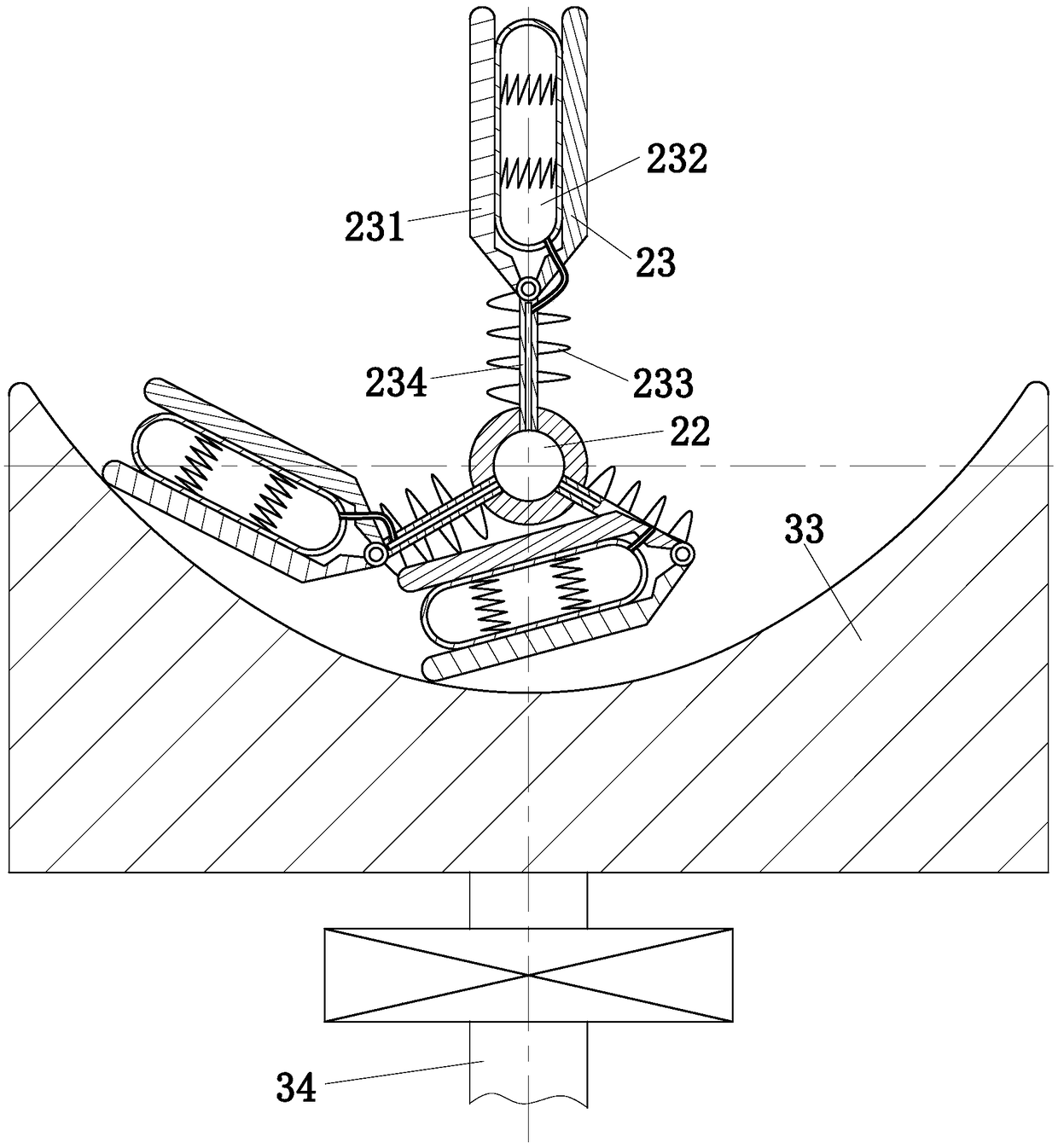

[0027] use Figure 1 to Figure 3 A coal chemical heavy oil sewage treatment process of the present invention is described as follows.

[0028] Such as figure 1 and figure 2 Shown, a kind of coal chemical heavy oil sewage treatment process of the present invention, this process comprises the steps:

[0029] Step 1: Pass the sewage into the heavy oil sewage treatment system for precipitation of heavy metal ions to produce sediment, and remove the sediment;

[0030] Step 2: After the sediment in the sewage is removed in step 1, continue to remove the heavy oil in the sewage through the heavy oil sewage treatment system;

[0031] Step 3: After the heavy oil in the sewage is removed in step 2, the sewage is passed into the anaerobic reactor for anaerobic dephenolization treatment; the anaerobic reactor is a UASB anaerobic reactor, and the hydraulic retention time is 4 to 7 hours. The temperature is 20-35°C; the anaerobic dephenolization treatment is added with anaerobic dephen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com