Environment-friendly flame-retardant polyolefin protective film, and preparation method thereof

A polyolefin and protective film technology, applied in the direction of film/sheet-like adhesives, adhesives, etc., can solve the problems of film breakage, large amount of flame retardants, inability to apply, etc., and achieve stable and good film blowing process. Flame retardant effect, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

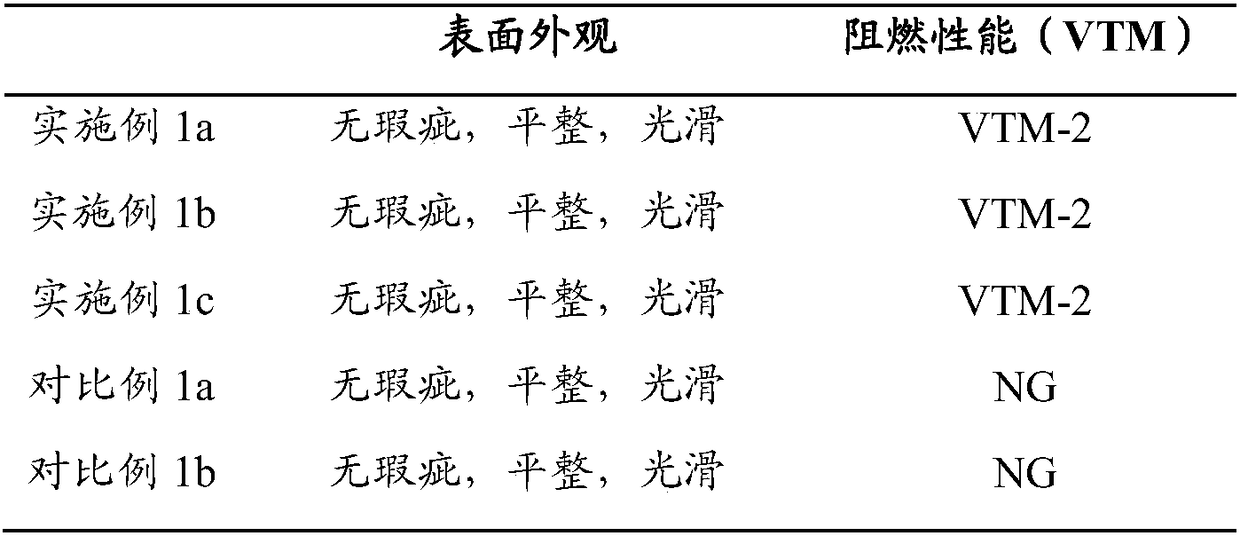

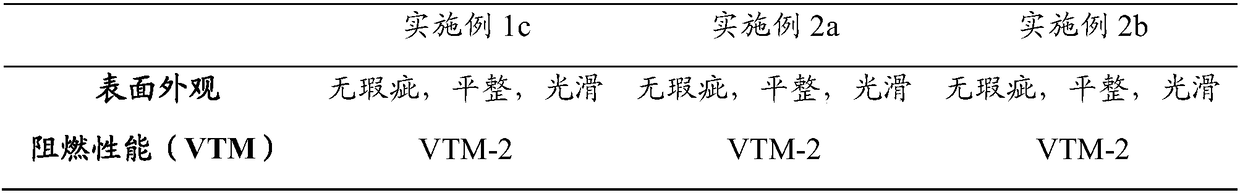

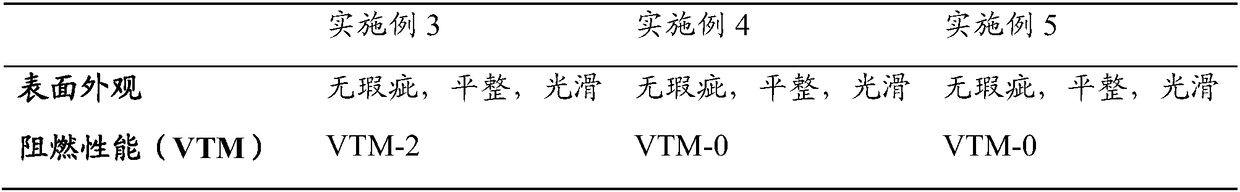

Examples

Embodiment 1

[0043] An environmentally friendly flame-retardant polyolefin protective film is made of the following components by weight:

[0044] 100 parts of polyethylene, 3 parts of composite flame retardant, 1 part of black masterbatch, 0.3 parts of antioxidant 1010 and 0.7 parts of zinc stearate.

[0045] Wherein said composite flame retardant is as follows:

Embodiment 1a

[0046] Example 1a: Tetrabromobisphenol A bis(2,3-dibromopropyl) ether 67w.t.%, antimony trioxide 33w.t.%;

Embodiment 1b

[0047] Example 1b: Tetrabromobisphenol A bis(2,3-dibromopropyl) ether 80w.t.%, antimony trioxide 20w.t.%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com