Preparation method of self-cleaning agent for kitchens

A technology of self-cleaning agent and kitchen, applied in the field of preparation of kitchen self-cleaning agent, achieving the effect of simple preparation method, easy production and preparation, and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

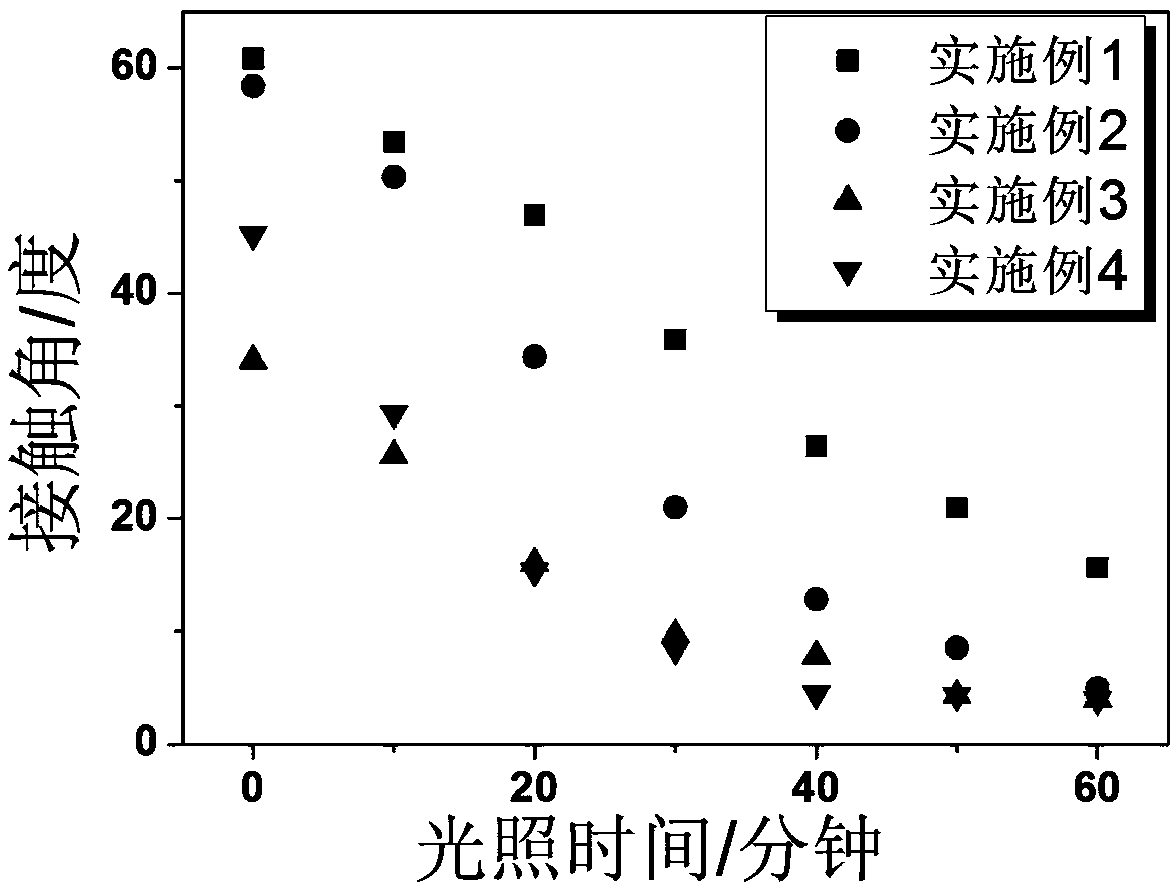

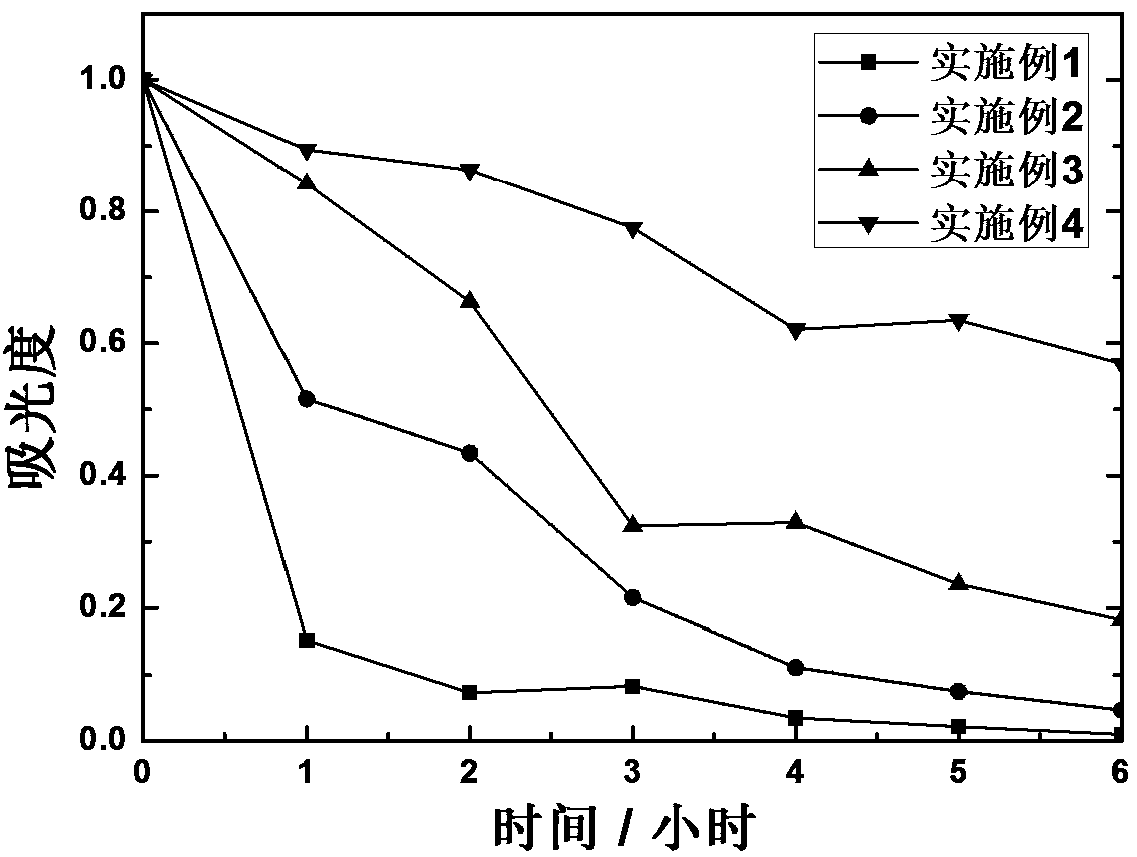

Embodiment 1

[0020] In the concrete implementation of the present invention, a kind of preparation method of self-cleaning agent for kitchen is, at first according to mass percentage: take by weighing particle diameter and be that 1nm, mass fraction are 99% of water-based nano-visible photocatalyst liquid of 10%, stir at 5000rpm Next, according to the ratio of 0.1% by mass percentage, add silica sol film-forming agent, add 0.9% by mass percentage of deionized water, and stir at a high speed of 5000rpm for 30min to obtain the spray precursor solution; then according to the filling volume of 80% of the spray precursor liquid is added to the spray tank, and finally the one-step pressure canning method is used to fill 20% of the dimethyl ether propellant and seal it, that is, a new type of kitchen self-cleaning agent that can be directly sprayed.

Embodiment 2

[0022] In the concrete implementation of the present invention, a kind of preparation method of self-cleaning agent for kitchen is, at first according to mass percentage: take by weighing particle diameter and be that 150nm, mass fraction are 98% of water-based nano-visible photocatalyst liquid of 40%, stir at 3000rpm Next, add alumina sol film-forming agent according to the proportion of 2% by mass percentage, and stir at a high speed of 3000rpm for 120min to obtain the spray precursor solution; then add the spray precursor solution to the spray tank according to the proportion of filling volume of 10%, and finally The one-step pressure canning method is filled with 90% of the propane butane propellant and then sealed to obtain a new type of kitchen self-cleaning agent that can be directly sprayed.

Embodiment 3

[0024] In the concrete implementation of the present invention, a kind of preparation method of self-cleaning agent for kitchen is, at first according to mass percentage: take by weighing particle diameter and be 35nm, mass fraction be 98% of water-based nano-visible photocatalyst liquid of 25%, stir at 4000rpm Next, add alumina sol film-forming agent according to the ratio of 1.5% by mass percentage, add deionized water with 0.5% by mass percentage, and stir at a high speed of 4000rpm for 60min to obtain the spray precursor solution; then according to the filling volume of 30 % ratio of the spray precursor solution into the spray tank, and finally use a one-step pressure canning method to fill 70% of the trichlorofluoromethane propellant and seal it to obtain a new type of kitchen self-cleaning agent that can be directly sprayed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com