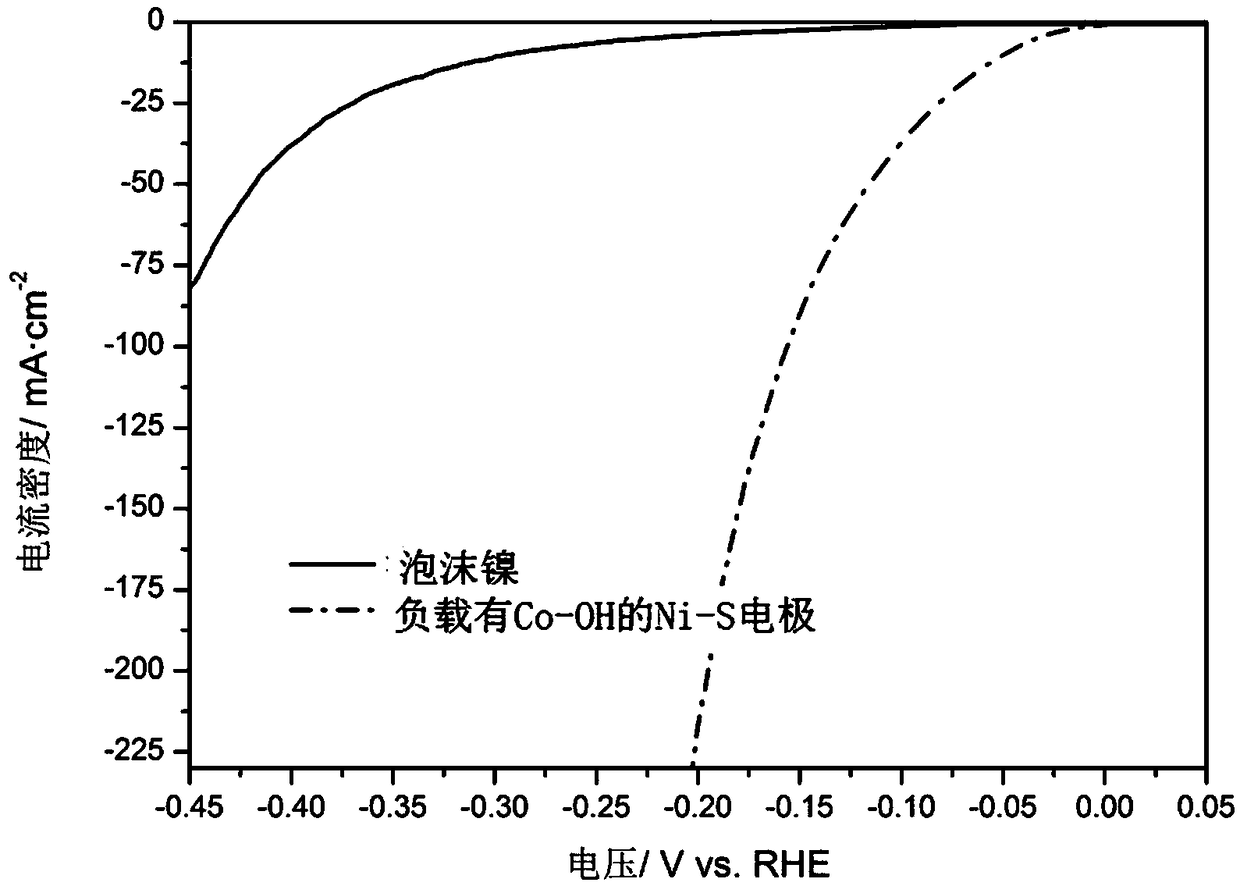

Ni-S high-efficient hydrogen evolution electrode loaded with Co-OH and preparation method thereof

A hydrogen evolution electrode, high-efficiency technology, applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problems of unpublished patent documents, etc., and achieve the effect of increasing conduction speed, increasing specific surface area, and enhancing adhesion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of Ni-S high-efficiency hydrogen evolution electrode loaded with Co-OH, its innovation lies in that it includes the following steps:

[0032] (1) Pretreatment of conductive substrate:

[0033] Choose tailored nickel foam with a size of 1×4cm; completely soak it with 100ml of acetone, and ultrasonically shake for 30 minutes to remove the residual oil stains on the surface of the foam nickel; rinse the soaked foam nickel with deionized water repeatedly Place it in the prepared 150ml, 3mol / L HCl, and ultrasonically shake for 15min to remove the oxide layer on the surface of the foamed nickel; finally, take the foamed nickel out of the solution and wash it with absolute ethanol and deionized water repeatedly until PH= 7. Put it in a vacuum drying box for vacuum drying and storage to prevent it from being re-oxidized and save it for subsequent use;

[0034] (2) Preparation of Ni-S nanosheet intermediate layer by hydrothermal method:

[0035] Using the hydrother...

Embodiment 2

[0047] A preparation method of Ni-S high-efficiency hydrogen evolution electrode loaded with Co-OH, its innovation lies in that it includes the following steps:

[0048] (1) Step (1) is the same as step (1) in Example 1;

[0049] (2) Preparation of Ni-S nanosheet intermediate layer by hydrothermal method:

[0050] Using the hydrothermal method, use 1.8mmol of thiourea as the precursor solution, stir evenly and ultrasonically shake for 40min, and place it in a 25ml PTFE hydrothermal reactor together with the processed foamed nickel; Hydrothermal reaction at ℃ for 6 hours. After the reactor is naturally cooled to room temperature, the electrode is taken out, the residue on the electrode surface is rinsed, and the middle layer of Ni-S nanosheet is obtained after keeping it in a vacuum drying oven at 60℃ for 8 hours;

[0051] (3) Secondary hydrothermal preparation of Co-OH catalyst layer:

[0052] After obtaining the Ni-S nanosheet intermediate layer prepared in the process of step (2), us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com