A method for constructing a catalytic hydrogen evolution electrode with fully exposed molybdenum disulfide active sites

A molybdenum disulfide and hydrogen evolution electrode technology, applied in electrodes, replication/marking methods, electrolysis components, etc., can solve the problems of easy-to-stack space structure design methods, large size of lamellae, lack of lamellae, etc., and achieve mass production. , the effect of increasing quantity and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

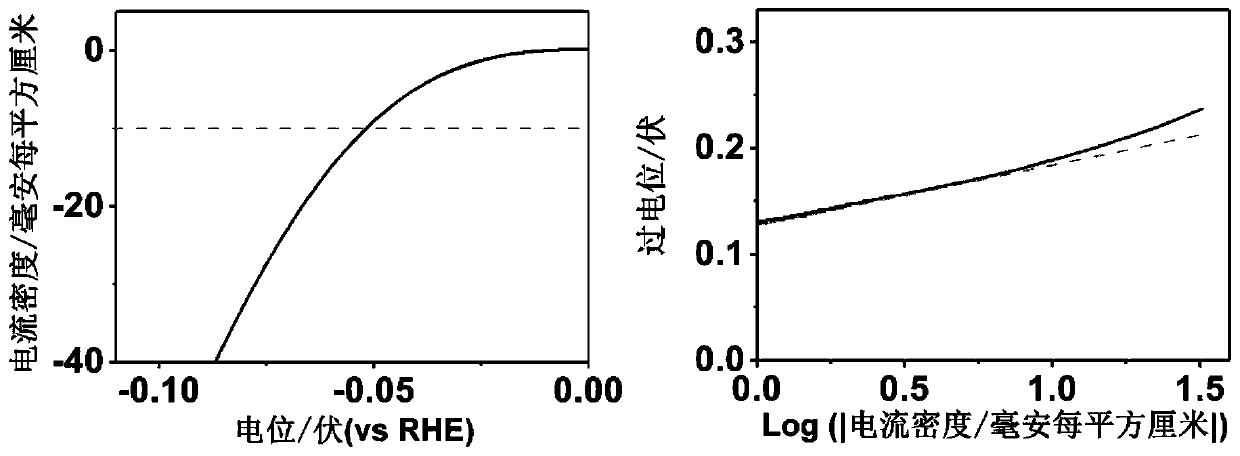

Embodiment 1

[0051] Mix 10mL ethanol and 10mL deionized water in a beaker, add 40mg of polyvinylpyrrolidone, then weigh 200mg of molybdenum disulfide powder raw material and 20mg of reduced graphene oxide powder raw material and disperse them in the mixed solution to prepare molybdenum disulfide suspension. Transfer the molybdenum disulfide suspension to an ultrasonic tank for liquid phase stripping, and centrifuge the molybdenum disulfide suspension after liquid phase ultrasonic treatment, and take two-thirds of the supernatant from the centrifuge tube to obtain molybdenum disulfide / Polyvinylpyrrolidone / reduced graphene oxide dispersion (ie, molybdenum disulfide nanosheet dispersion) is the active material for catalytic hydrogen evolution.

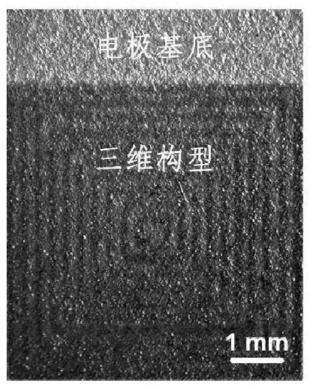

[0052] Molybdenum disulfide / polyvinylpyrrolidone / reduced graphene oxide was spray-printed on a Teslin paper base covered with a copper conductive film by inkjet printing. Its patterned configuration is as follows: First, use a plane figure (area 0.5...

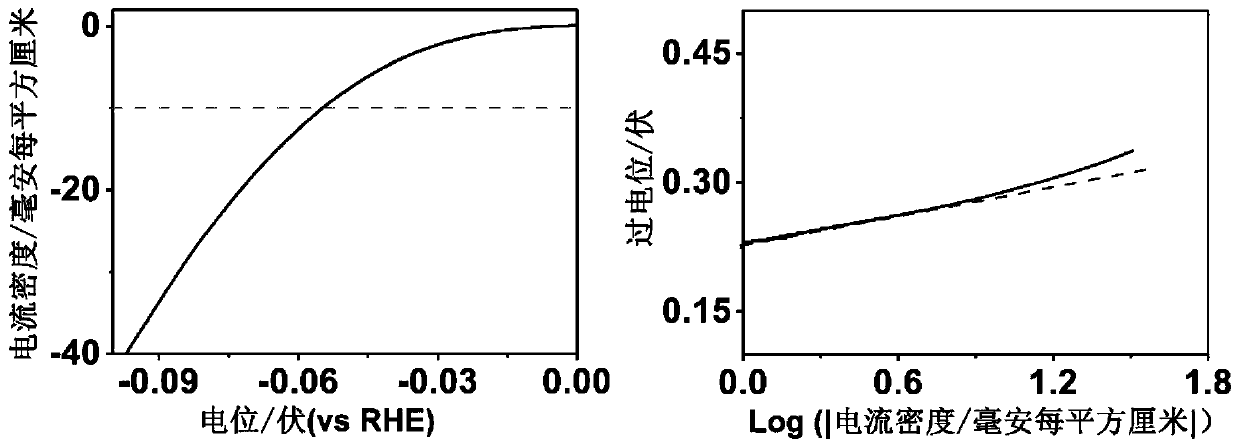

Embodiment 2

[0056] Mix 10mL ethanol and 10mL deionized water in a beaker, add 40mg of polyvinylpyrrolidone, then weigh 200mg of molybdenum disulfide powder raw material and 20mg of reduced graphene oxide powder raw material and disperse them in the mixed solution to prepare molybdenum disulfide suspension. Transfer the molybdenum disulfide suspension to an ultrasonic tank for liquid phase stripping, and centrifuge the molybdenum disulfide suspension after liquid phase ultrasonic treatment, and take two-thirds of the supernatant from the centrifuge tube to obtain molybdenum disulfide / Polyvinylpyrrolidone / reduced graphene oxide dispersion (ie, molybdenum disulfide nanosheet dispersion) is the active material for catalytic hydrogen evolution.

[0057] Molybdenum disulfide / polyvinylpyrrolidone / reduced graphene oxide was spray-printed on a Teslin paper base covered with a copper conductive film by inkjet printing. Its patterned configuration is as follows: First, use a plane figure (area 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com