Preparation method of magnesium alloy surface micro-arc oxidation/intelligent slow-release structure integrated composite coating

A technology of micro-arc oxidation and composite coating, which is applied in the field of metal surface treatment, can solve the problems of failure to successfully build a sustained-release structure, large structural size of sustained-release capsules, poor mechanical strength, etc., and achieve optimal pH response swelling and slow-release characteristics, Ensure mechanical stability and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing a MAO film / intelligent slow-release structure integrated composite coating on the surface of a magnesium alloy. First, a layer of dense MOA skeleton structure is prepared on the surface of the magnesium alloy. On this basis, n-alkyl methacrylic acid Ester changes the hydrophobic unit of the copolymer, adjusts the concentration required for ionization, introduces polyethylene glycol group grafting, and constructs a hydrophobic stable complex of hydrogen bonds between the polymer networks. In addition, the polymer network is grafted and modified by vinyl silane , using the -Si-OH of the silane branch to condense with the -OH group on the surface of the MAO membrane pore wall to form a Mg-O-Si bond, forming a pinning effect, thereby improving the mechanical stability of the sustained-release structure. Finally, the MAO / SRH integrated self-healing coating is realized.

[0026] The method specifically includes the following steps...

Embodiment 1

[0043] 1. Configuration of micro-arc oxidation. Put the magnesium alloy test piece with AZ91D as the substrate into the electrolyte and perform micro-arc oxidation treatment. The composition of the micro-arc oxidation electrolyte is: sodium phosphate 9g / L, sodium hydroxide 8g / L, and the rest is deionized water; micro-arc oxidation Oxidation control parameters are: mother wave voltage is 420V, wavelet voltage is 165V, carrier frequency is 1100Hz, treatment time is 45 minutes, oxide film thickness is 26±2μm, the oxide film is a porous ceramic film with a porosity of 32%~ 35%, and the pore size is 1-3 μm.

[0044] 2. Polymerization solution preparation. Mix n-AMA and PEGMA to form, n-AMA and PEGMA are mixed and stirred at a molar ratio of n(n-AMA):n(PEGMA)=4.2:3.

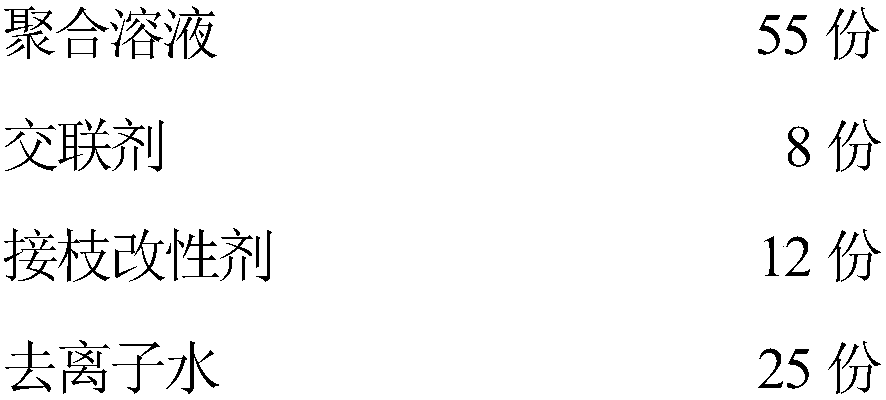

[0045] 3. Hydrosol modification reaction preparation. After mixing the polymerization solution, the crosslinking agent, the graft modifier, and deionized water in parts by weight, the mixture is continuously stirred...

Embodiment 2

[0051] 1. Configuration of micro-arc oxidation. Put the magnesium alloy test piece with ZM6 as the matrix into the electrolyte, and perform micro-arc oxidation treatment. The composition of the micro-arc oxidation electrolyte is: sodium phosphate 15g / L, sodium hydroxide 12g / L, sodium borate 10g / L, and the rest are Deionized water; micro-arc oxidation control parameters are: mother wave voltage is 520V, wavelet voltage is 170V, carrier frequency is 1300Hz, treatment time is 55 minutes, oxide film thickness is 27±1μm, the oxide film is a porous ceramic film, The porosity is 37% to 40%, and the pore diameter is 3 to 6 μm.

[0052] 2. Polymerization solution preparation. Mix n-AMA and PEGMA to form, n-AMA and PEGMA are mixed and stirred at a molar ratio of n(n-AMA):n(PEGMA)=6:2.5.

[0053] 3. Hydrosol modification reaction preparation. After mixing the polymerization solution, the crosslinking agent, the graft modifier, and deionized water in parts by weight, the mixture is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com