High tensile permeable concrete sandwich structure and preparation method

A permeable concrete and sandwich technology, applied in the field of building materials, can solve the problems of complex construction process, low tensile strength, easy corrosion of steel bars, etc., and achieve the effect of expanding the scope of application, good tensile strength, and ensuring tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In this embodiment, the fiber material is basalt fiber.

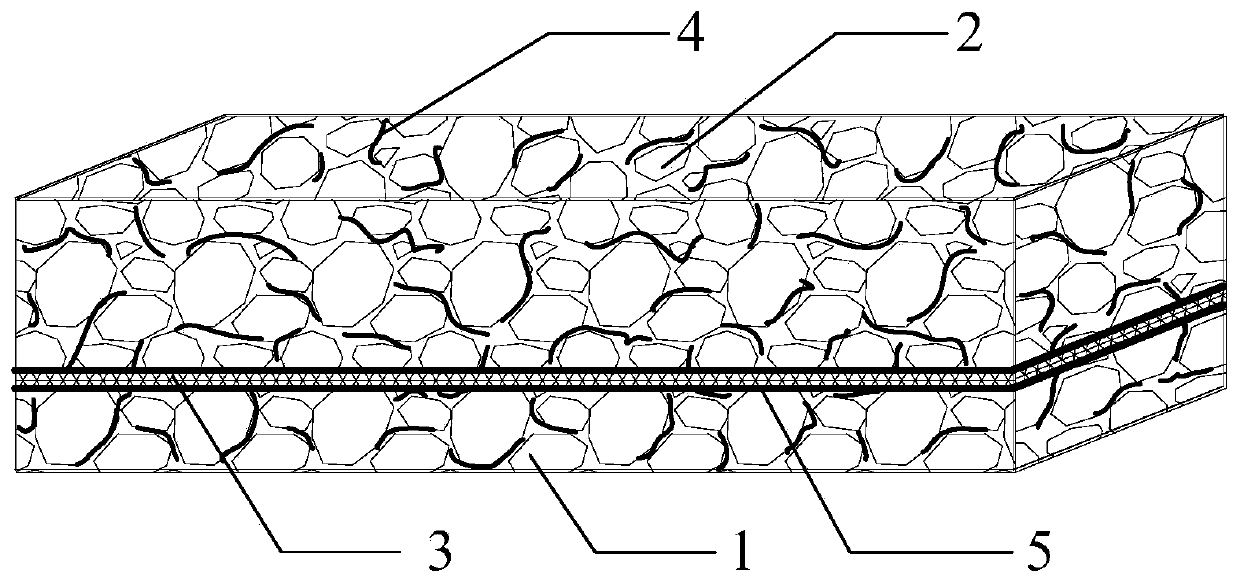

[0052] This embodiment provides a high tensile permeable concrete sandwich beam structure, see figure 1 As shown, the beam structure includes the lower permeable concrete 1, the upper permeable concrete 2, the geogrid reinforcement layer 3, the bonding layer 5, and the basalt fibers 4 evenly distributed in the lower permeable concrete 1 and the upper permeable concrete 2. Geogrid reinforcement layer 3 is tiled at the bottom of the distance beam where h represents beam height. The bonding layer 5 selects room temperature curable epoxy resin glue, and evenly coats the upper and lower surfaces of the geogrid reinforcement layer 3 .

[0053] In this embodiment, the lower permeable concrete 1 and the upper permeable concrete 2 are prepared by using pervious concrete, and the pervious concrete is prepared by mixing cement, fly ash, coarse aggregate, water and a water reducer. Among them, ordinary portland cement wi...

Embodiment 2

[0070] This embodiment is used to provide comparative experiments and experimental data.

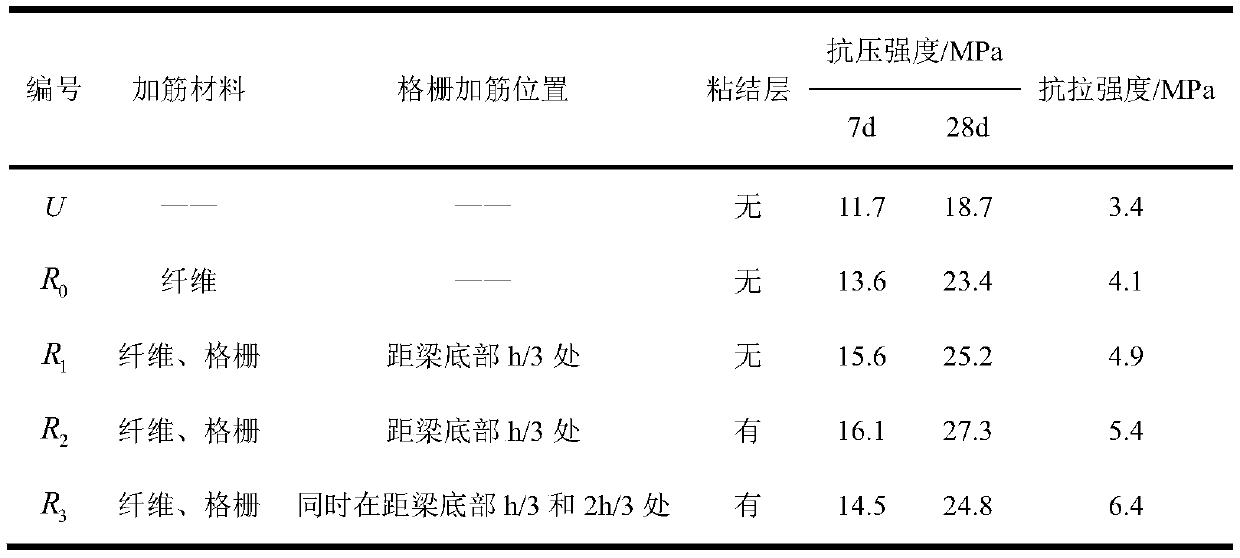

[0071] Fabrication of permeable concrete beam structures U, R 0 , R 1 and high tensile permeable concrete sandwich beam structure R 2 , R 3 . The beam structure U has no geogrid reinforcement layer, bonding layer and basalt fiber, and is only the main body of the permeable concrete structure. Beam structure R 0 There is no geogrid reinforcement layer and bonding layer, and only basalt fibers are evenly distributed in the main body of the pervious concrete structure. Beam structure R 1 In the main body of the permeable concrete structure, a geogrid reinforcement layer is flatly laid, and basalt fibers are evenly distributed, but the upper and lower surfaces of the geogrid reinforcement layer are not coated with a bonding layer. Beam structure R 2 and R 3 Manufactured by the method of Example 1, the geogrid reinforcement layer is tiled in the main body of the permeable concrete st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com