Drill string vibration drag reduction method for near-horizontal long borehole directional drilling in coal mine

A technology of directional drilling and long drilling, applied in directional drilling, vibration drilling, vibration generating device, etc., can solve the problems of poor track controllability, rapid wear of drill bits, etc., to reduce the feed force and reduce the size of the drill string Friction resistance, the effect of reducing the stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

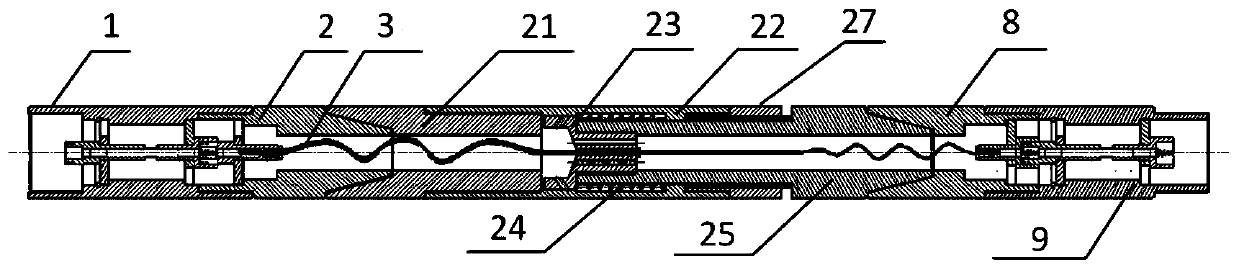

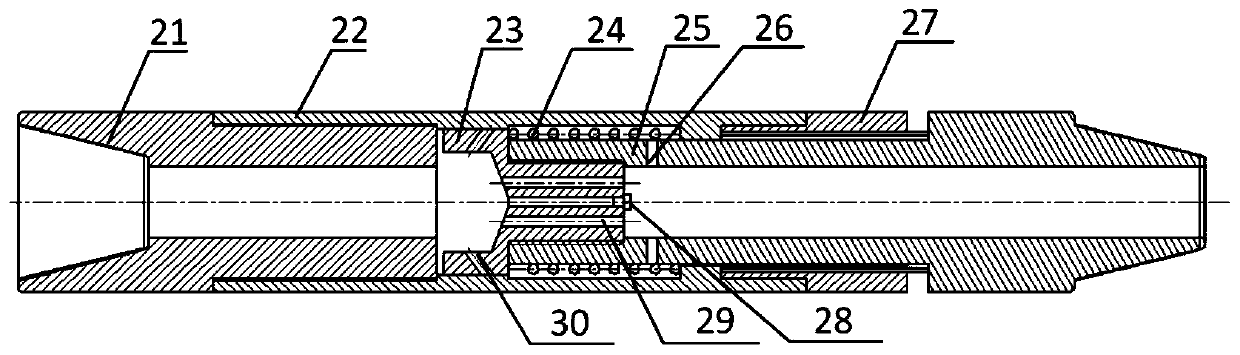

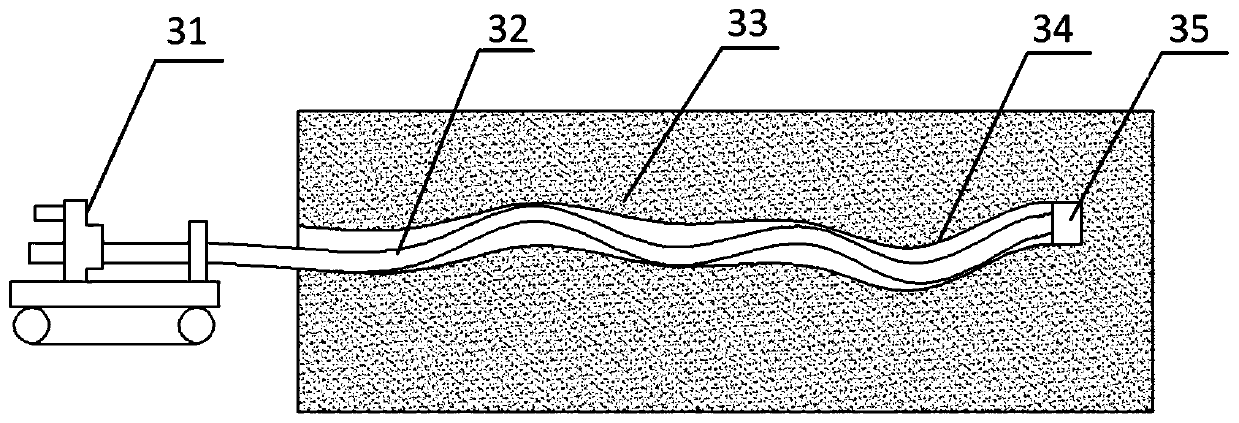

[0028] see figure 1 and 2 , shows the communicable vibration generator used in the method for reducing vibration and drag of the drill string for near-horizontal long boreholes in underground coal mines according to the present invention.

[0029] The communicable vibration generator includes an upper communication handle 1, an upper transition handle 2, a vibration nipple ( figure 2 ), a flexible communication line 3, a lower transition handle 8 and a lower communication handle 9, the upper communication handle 1 and the lower communication handle 9 are connected with the cable drill pipe for directional drilling in the coal mine underground, and the structure and principle are the same as those of the mature coal mine underground The cable drill pipe is the same, so I won’t go into details here. The upper transition joint 2 is connected to the upper communication joint 1 and the vibration joint, the lower transition joint 8 is connected to the vibration joint and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com