An underground pump monitoring device for coalbed methane drainage and gas recovery

A monitoring device and a technology for drainage and production wells, which are applied in the directions of surveying, earth-moving drilling, wellbore/well components, etc., can solve the problem that the real parameter changes at the bottom of the coalbed methane wellbore cannot be accurately reflected, the drainage and production production is affected, and long-term online monitoring is not possible. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

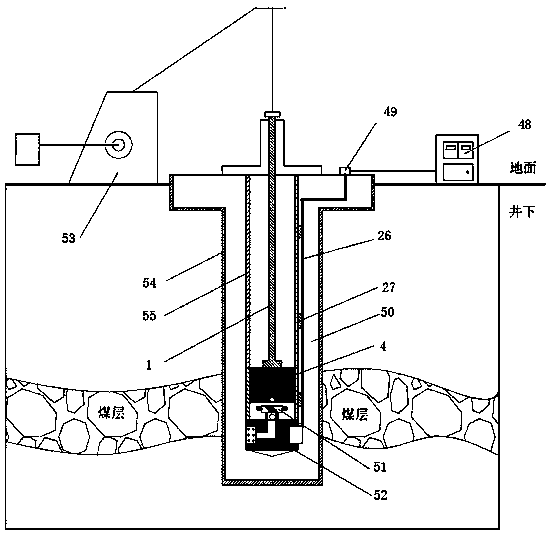

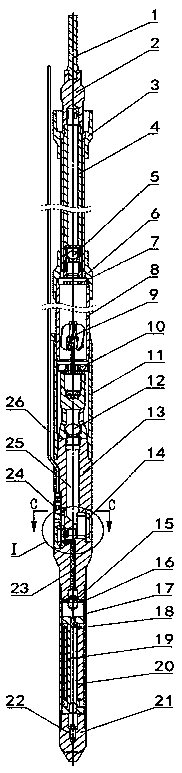

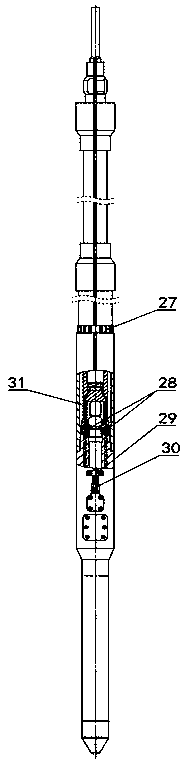

[0044] see figure 1 , an underground pump monitoring device for coalbed methane drainage. The overall system is mainly composed of a ground collection and transmission system 48, a wellhead sealing device 49, an armored cable 26, a cable collar 27, an oil casing annulus 50, and a pump barrel assembly 4 , the disturbance assembly 51 in the pump, and the monitoring device 52 with the pump. Such as figure 1 As shown, after the pump monitoring device 52 is connected with the disturbance assembly 51 in the pump, it is installed under the pump barrel assembly 4 of the conventional drainage pump to replace the original fixed valve assembly; one end of the armored cable 26 After being connected with the pump monitoring device 52 through the cable joint 30, it is lowered into the well bottom with the tubing, and the armored cable 26 is distributed in the tubing ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com