Fuel oil and fuel gas steam boiler

A gas steam and fuel oil technology, applied in steam boilers, steam generation, combustion methods, etc., can solve the problems of poor heat exchange effect, large fuel consumption, short flow of smoke pipes, etc., and achieve improved performance, long service life, and energy saving. The effect of environmentally friendly heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

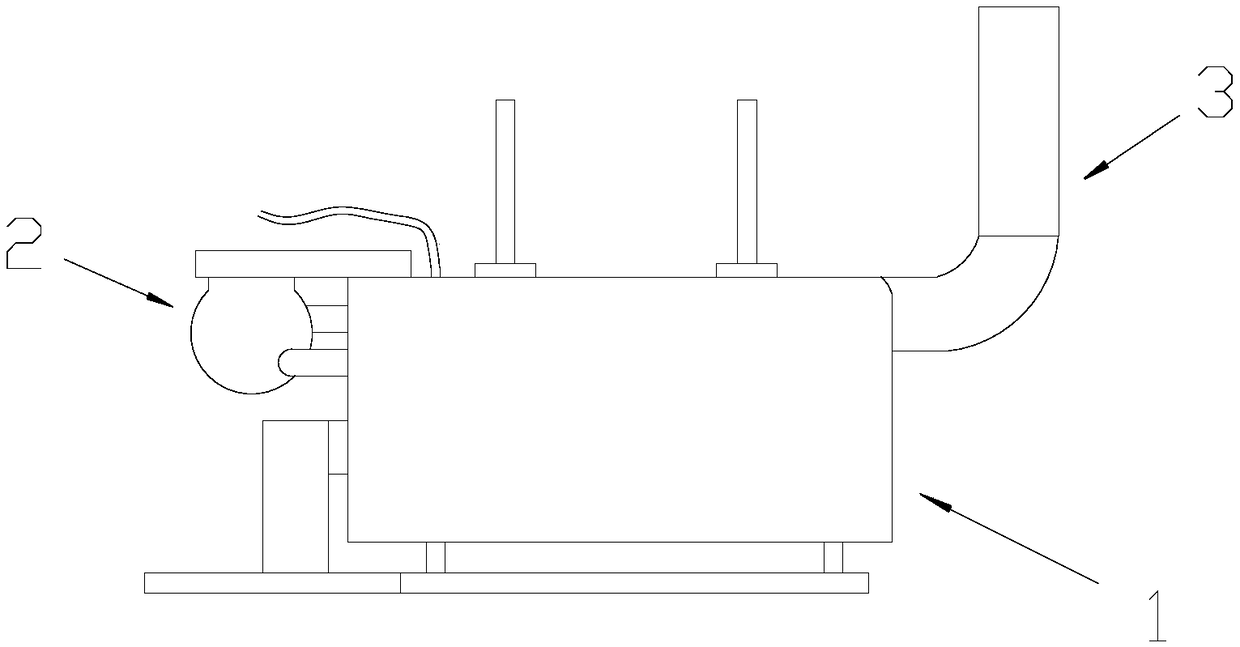

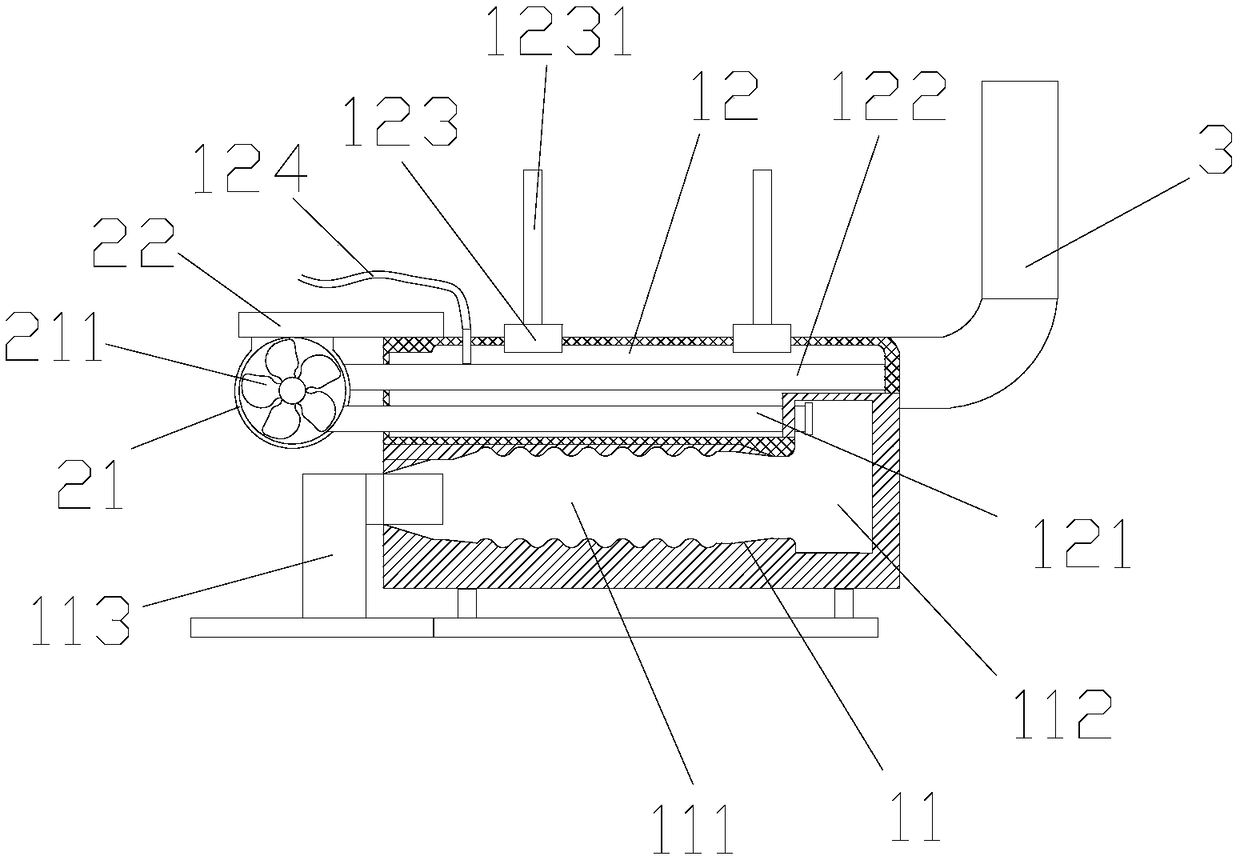

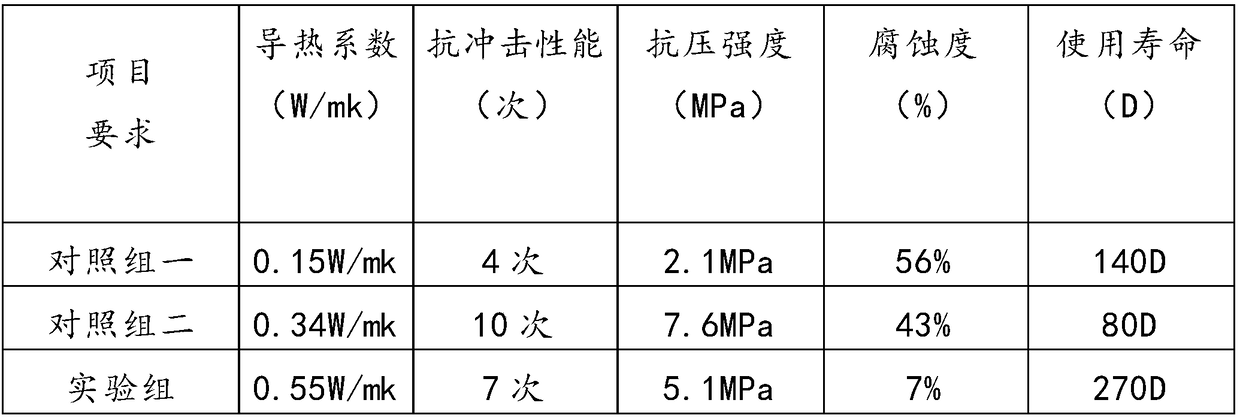

[0030] A fuel gas steam boiler, such as figure 1 As shown, it includes a combustion furnace body 1, a turbocharger blower 2 arranged above the combustion furnace body 1 and communicated with the combustion furnace body 1, and a chimney 3 arranged on the other side of the combustion furnace body 1; Such as figure 2 As shown, the combustion furnace body 1 includes a combustion chamber 11, and a water storage chamber 12 arranged above the combustion chamber 11; The tempering chamber 112, and the burner 113 that is arranged at the other end of the combustion passage 111 and is located outside the combustion chamber 11; the water storage chamber 12 is provided with one end communicating with the tempering chamber 112 and the other end communicating with the turbocharger The first return pipe 121 connected to the compressor 2, and the second return pipe 122 arranged above the first return pipe 121, one end communicated with the turbocharger fan 2, and the other end communicated wi...

Embodiment 2

[0042] A fuel gas steam boiler, such as figure 1 As shown, it includes a combustion furnace body 1, a turbocharger blower 2 arranged above the combustion furnace body 1 and communicated with the combustion furnace body 1, and a chimney 3 arranged on the other side of the combustion furnace body 1; Such as figure 2 As shown, the combustion furnace body 1 includes a combustion chamber 11, and a water storage chamber 12 arranged above the combustion chamber 11; The tempering chamber 112, and the burner 113 that is arranged at the other end of the combustion passage 111 and is located outside the combustion chamber 11; the water storage chamber 12 is provided with one end communicating with the tempering chamber 112 and the other end communicating with the turbocharger The first return pipe 121 connected to the compressor 2, and the second return pipe 122 arranged above the first return pipe 121, one end communicated with the turbocharger fan 2, and the other end communicated wi...

Embodiment 3

[0054] A fuel gas steam boiler, such as figure 1 As shown, it includes a combustion furnace body 1, a turbocharger blower 2 arranged above the combustion furnace body 1 and communicated with the combustion furnace body 1, and a chimney 3 arranged on the other side of the combustion furnace body 1; Such as figure 2 As shown, the combustion furnace body 1 includes a combustion chamber 11, and a water storage chamber 12 arranged above the combustion chamber 11; The tempering chamber 112, and the burner 113 that is arranged at the other end of the combustion passage 111 and is located outside the combustion chamber 11; the water storage chamber 12 is provided with one end communicating with the tempering chamber 112 and the other end communicating with the turbocharger The first return pipe 121 connected to the compressor 2, and the second return pipe 122 arranged above the first return pipe 121, one end communicated with the turbocharger fan 2, and the other end communicated wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com