An automated pretreatment method for the detection of banned harmful aromatic amine dyes

An aromatic amine and dye technology, applied in the field of dye component detection, can solve problems such as deviation personnel and poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

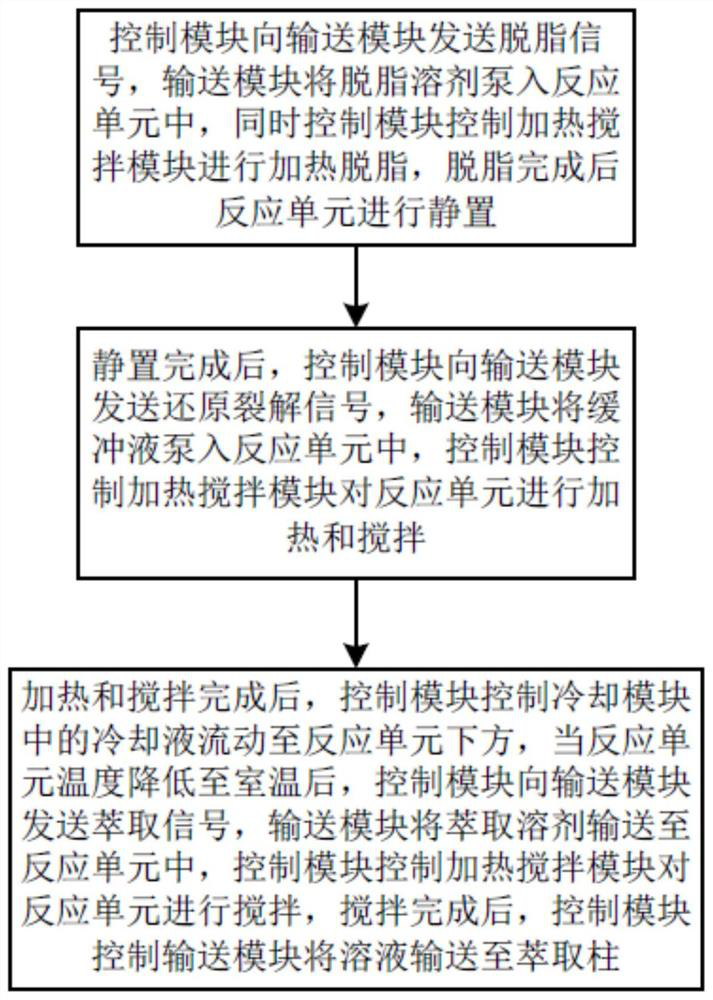

Method used

Image

Examples

Embodiment 1

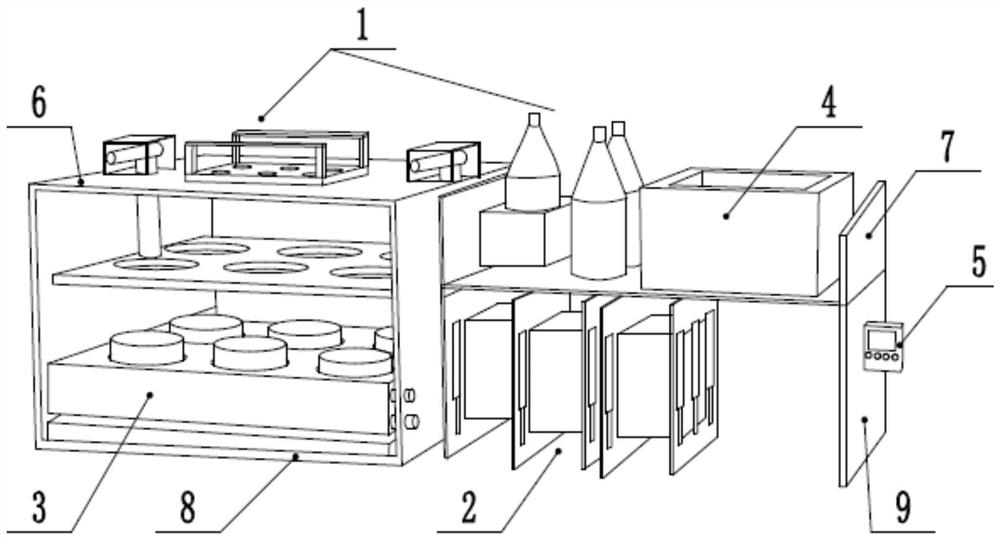

[0041] In order to realize the automated pretreatment method for the detection of harmful aromatic amine dyes prohibited in the first embodiment, the first embodiment also discloses a pretreatment system, such as figure 2 As shown, it includes a control module 5, a cooling module 4, a delivery module 2, a heating and stirring module 3, and at least one set of reaction modules 1 for sample degreasing, dye reduction and extraction. The accompanying drawings draw a set of reaction modules 1 as an example, and this implementation Example samples take leather as an example.

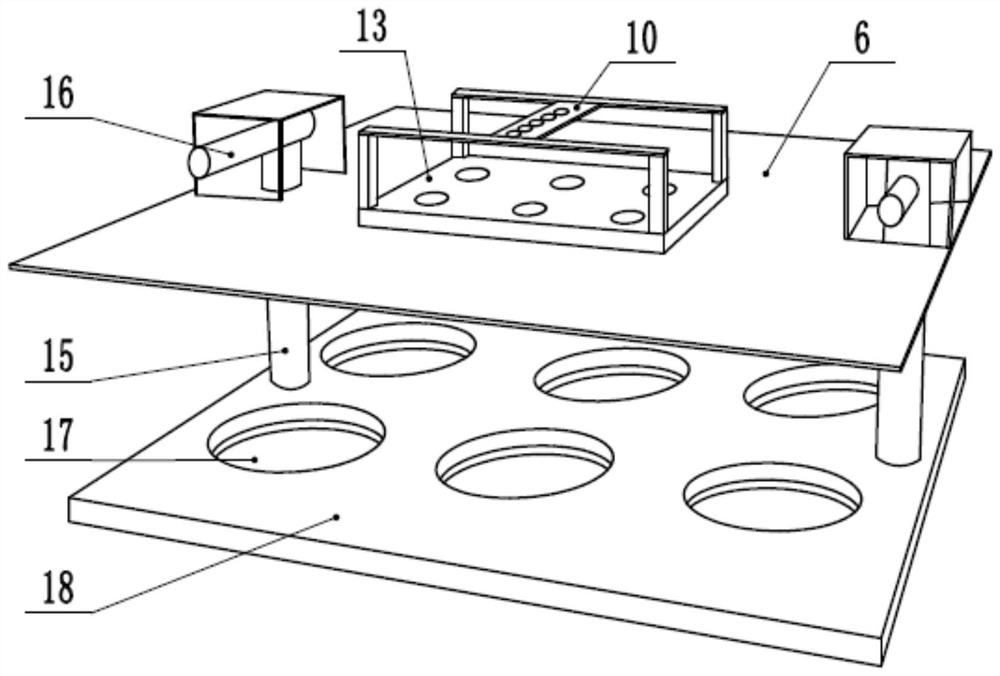

[0042] like image 3 , Figure 4 and Figure 5 As shown, the reaction module 1 includes a plurality of reaction units, and the reaction unit is the reaction cup 31. In this embodiment, six reaction cups 31 are taken as an example. The reaction module 1 is equipped with a support module, and the support module includes a first bracket 6, and a second support module. The second support 7 that a support 6 is ...

Embodiment 2

[0068] The difference from the first embodiment above is that the sample to be tested is selected from textiles, the first pump 32 is turned off without degreasing, and the textile sample does not need to be degreased, and the volume of the solution delivered into the cuvette 31 is set according to the textile, and Another timing program stored in the timing unit performs textile detection timing.

Embodiment 3

[0070] The difference from Embodiment 1 or Embodiment 2 is that, if Figure 9 As shown, the top surface of the sealing cover 18 is welded with a gas cover 36 that completely covers the sealing ring 17, and the sealing cover 18 inside each sealing ring 17 is provided with an air hole 37 communicating with the gas cover 36, and the top of the gas cover 36 The upper airtightness is connected with an air guide tube 40, and the end of the air guide tube 40 is airtightly connected with a fixed-volume air tank 41, and the air guide tube 40 is equipped with an air suction pump 38 positioned between the air cover 36 and the air tank 41. The air pump 38 draws the volatilized organic solvent gas in the cuvette 31 into the gas tank 41, i.e. n-hexane, and the air guide tube 40 between the air pump 38 and the gas tank 41 is equipped with a one-way valve to inflate the gas tank 41 side. The valve 39 is airtightly connected with the air outlet pipe 42 on the air tank 41. Quantitative oxygen i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com