Detection and determination method for battery micro short circuit

A judging method and micro-short-circuit technology, which are applied to the components of electrical measuring instruments, measuring electronics, and measuring devices, can solve the problems of high battery production cost and long cycle, and achieve simple structure, low production cost and improved quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

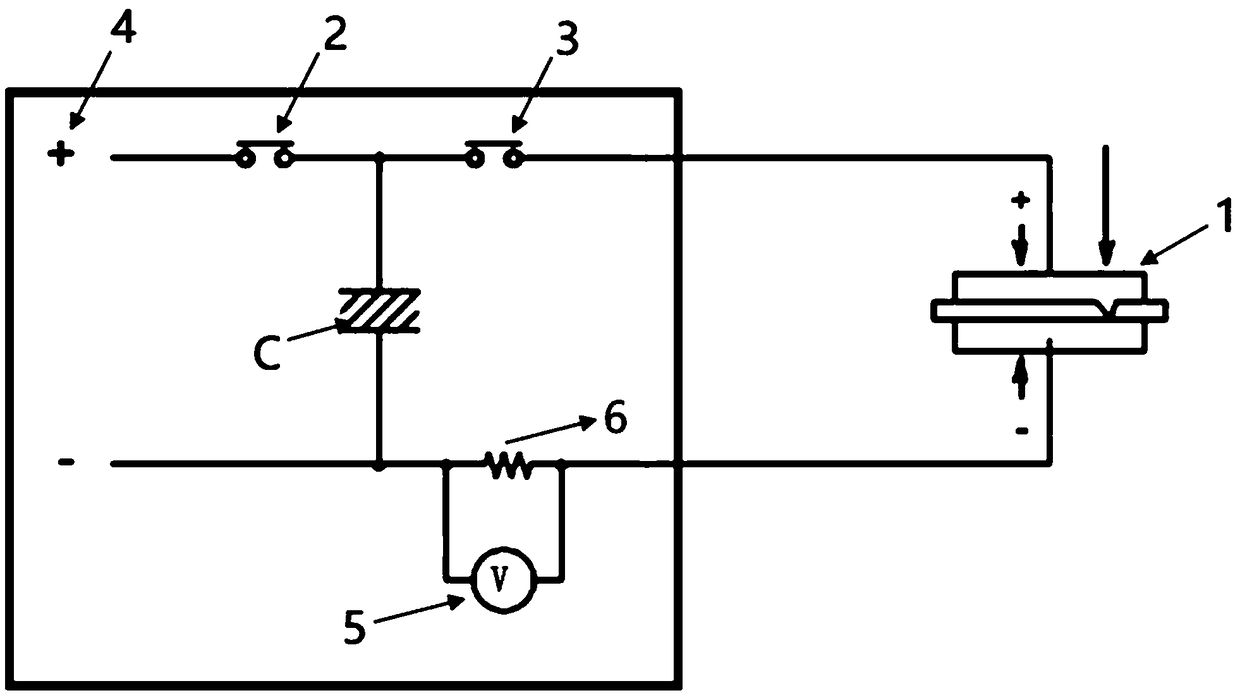

[0018] A method for detecting and judging a battery micro-short circuit. The non-fluid nickel-hydrogen D6000 battery is fixedly installed in a battery fixing fixture of a battery micro-short circuit detection device, and the non-fluid battery is pressurized. The positive end of the non-fluid nickel-metal hydride battery is Contact with the positive terminal of the battery fixing jig, the negative terminal of the unfilled NiMH battery is in contact with the negative terminal of the battery fixing jig, and pressurize the battery fixing jig through the air cylinder, so that the battery fixing jig can pressurize the unfilled battery And its pressure value is above 5N, then turn on the 380V constant current regulated power supply to charge the capacitor in the battery micro-short circuit detection device for 46ms, after the capacitor is fully charged, disconnect the 380V constant current regulated power supply and The control capacitor discharges the unfilled battery instantaneously...

Embodiment 2

[0021] A method for detecting and judging a battery micro-short circuit, the steps of which are basically the same as those of the method for detecting and judging a battery micro-short circuit in Example 1. The power supply in the short-circuit detection device is a 220V constant current regulated power supply, the capacitor charging time is 80ms, the capacitor instantaneous discharge time is 25ms, and the set standard current value is 2.5A.

Embodiment 3

[0023] A method for detecting and judging a battery micro-short circuit, the steps of which are basically the same as those of the method for detecting and judging a battery micro-short circuit in Embodiment 1. The difference is: the battery is a lithium battery 32650 without liquid injection, and the set standard current The value is 7A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com