Heat sink strip of PTC heat-sensitive material heating device, heating device and special electrical appliance

A technology of heating devices and heat-sensitive materials, applied in the direction of heating element materials, heating element shapes, ohmic resistance heating parts, etc., can solve problems such as high manufacturing costs, heat dissipation ripples, poor bonding strength of heat conduction sheets, and poor welding, etc., to achieve Improve comfort and environmental protection functions, increase heat dissipation area and heat, and improve the effect of the use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

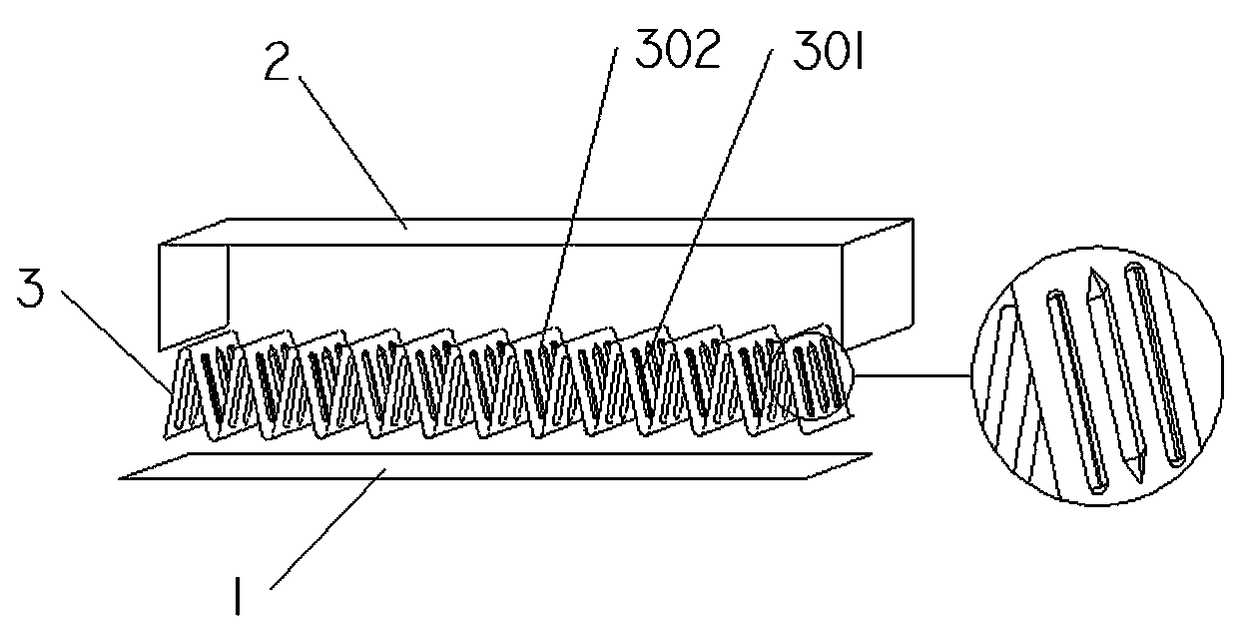

[0024] Such as figure 1 The heat dissipation strip of the PTC heat-sensitive material heating device shown includes a heat dissipation corrugation 3 clamped by a heat conduction flat sheet 1 and a folded edge positioning heat conduction sheet 2. The height direction of the heat dissipation corrugation 3 has a concave surface 301 and a folding fan surface at the same time. 302, the concave surface 301 and the angled surface 302 are perpendicular to the width direction of the heat dissipation strip; the heat dissipation corrugation is formed by rolling an aluminum strip through a pair of continuous gears of a gear hobbing machine, and each pair of gears of the gear hobbing machine Each tooth surface is provided with an inner concave / external convex surface and an angled surface parallel to the tooth height direction. Through the opposite meshing transmission of the gears, the aluminum strip is rolled out at the same time as the width direction of the heat dissipation corrugation....

Embodiment 2

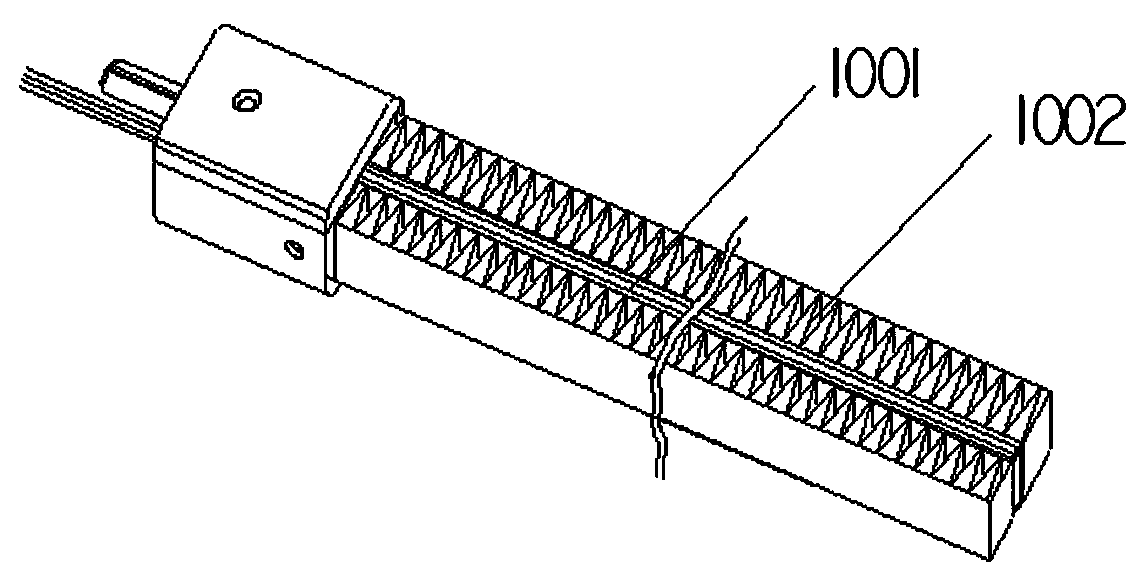

[0026] Such as figure 2 The heating device of the PTC heat-sensitive material shown contains the heat dissipation strip described in the above-mentioned embodiment, including a PTC heating element, and the main component of the PTC heating element is Ba (1-x) PbxTiO3, the Ti is extracted from rutile TiO2 raw ore, and the molar ratio of Ti in the main component is greater than 1.00%; it also includes a PTC heating element, which is penetrated into a hollow heat-conducting aluminum tube by insulating After the heating core 1001 of the film-coated PTC thermal heating element is pasted in parallel between the two electrode sheets, the heat-conducting surface of the aluminum tube is pressed to eliminate the gap between the heating core in the heating body and the inner wall of the aluminum tube. A surface-insulated PTC heating element is formed, and the PTC heat-sensitive material heating element is formed after the heat-conducting surface of the aluminum tube of the heating eleme...

Embodiment 3

[0028] An electrical appliance, containing the heat-generating device of the PTC heat-sensitive material described in the above embodiments, the electrical appliance is selected from air conditioners, heaters, hot air curtains, Yuba, dehumidifiers, air purifiers, clothes dryers, car heaters or dehumidifiers A type of atomizing frost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com