Preparation method for silver nanorings

A silver nanometer and nanosilver technology, which is applied in the field of preparation of silver nanorings, can solve the problems of low yield of silver nanorings and the like, and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

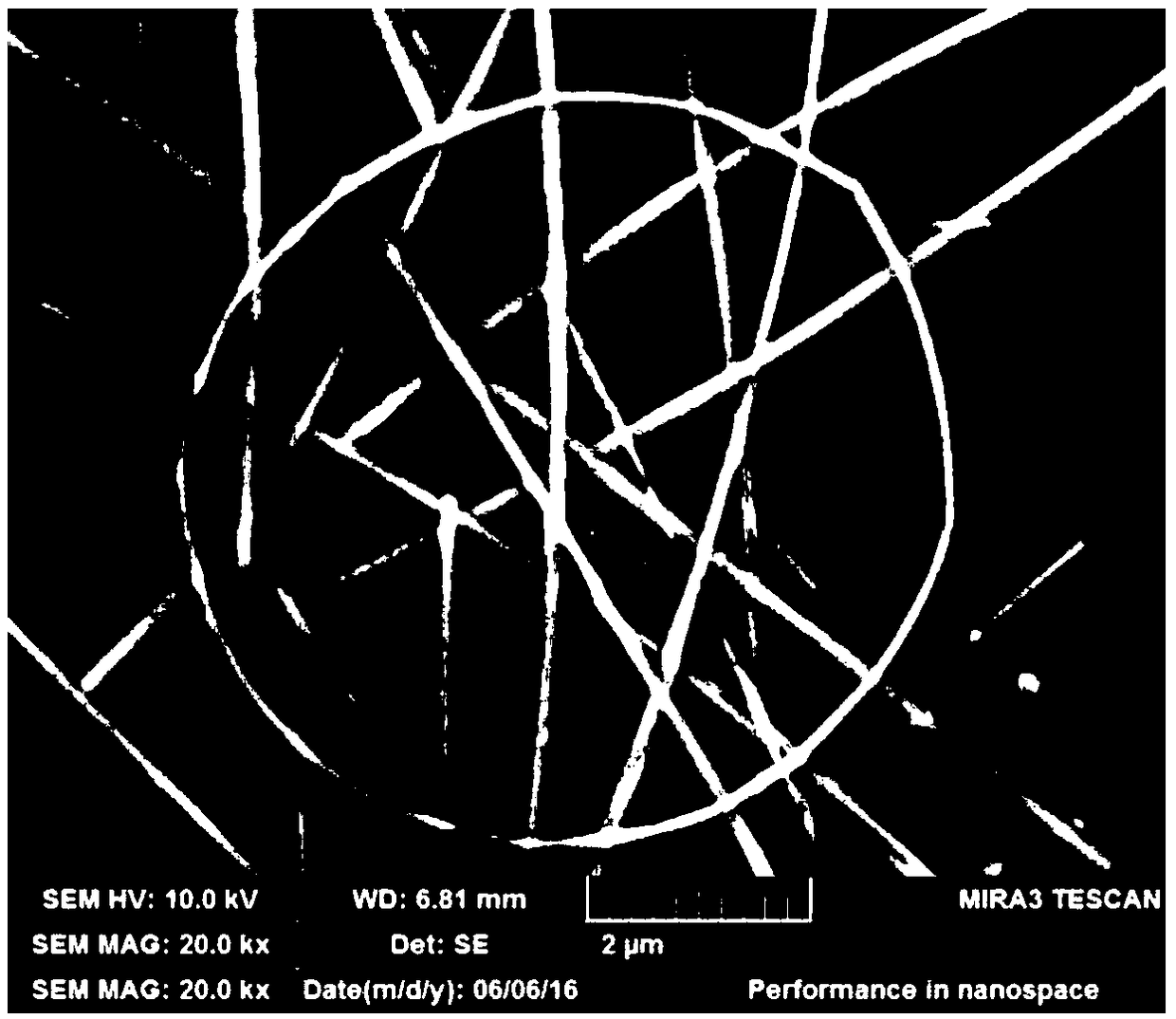

Image

Examples

preparation example Construction

[0029] A kind of preparation method of silver nano ring of the present invention, comprises the following steps:

[0030] (1) Weigh polyvinylpyrrolidone and silver nitrate according to the molar ratio of 1-10:1, polyvinylpyrrolidone includes small molecular weight polyvinylpyrrolidone with a molecular weight of 55000-58000 and large molecular weight polyvinylpyrrolidone with a molecular weight of 360000-1300000 ,;

[0031] (2) respectively dissolving small molecular weight polyvinylpyrrolidone and large molecular weight polyvinylpyrrolidone in ethylene glycol to make small molecular weight polyvinylpyrrolidone-ethylene glycol solution and large molecular weight polyvinylpyrrolidone-ethylene glycol solution for subsequent use;

[0032] (3) silver nitrate is dissolved in the polyvinylpyrrolidone-ethylene glycol solution of small molecular weight under refrigerated environment to make silver nitrate-polyvinylpyrrolidone-ethylene glycol solution for subsequent use;

[0033] (4) T...

Embodiment 1

[0046] A preparation method for silver nanorings, comprising the following steps:

[0047] (1) Take polyvinylpyrrolidone and silver nitrate according to the molar ratio of 2:1. Polyvinylpyrrolidone includes small molecular weight polyvinylpyrrolidone with molecular weight of 55000 and large molecular weight polyvinylpyrrolidone with molecular weight of 360000. Small molecular weight polyvinylpyrrolidone The mass ratio with large molecular weight polyvinylpyrrolidone is 1:1;

[0048] (2) respectively dissolving small molecular weight polyvinylpyrrolidone and large molecular weight polyvinylpyrrolidone in ethylene glycol to make small molecular weight polyvinylpyrrolidone-ethylene glycol solution and large molecular weight polyvinylpyrrolidone-ethylene glycol solution for subsequent use;

[0049] (3) silver nitrate is dissolved in the polyvinylpyrrolidone-ethylene glycol solution of small molecular weight at 0 ℃ to make silver nitrate-polyvinylpyrrolidone-ethylene glycol solutio...

Embodiment 2

[0053] A preparation method for silver nanorings, comprising the following steps:

[0054] (1) Take polyvinylpyrrolidone and silver nitrate according to the molar ratio of 8:1. Polyvinylpyrrolidone includes small molecular weight polyvinylpyrrolidone with molecular weight of 58000 and large molecular weight polyvinylpyrrolidone with molecular weight of 1300000. Small molecular weight polyvinylpyrrolidone The mass ratio with large molecular weight polyvinylpyrrolidone is 0.8:1;

[0055] (2) respectively dissolving small molecular weight polyvinylpyrrolidone and large molecular weight polyvinylpyrrolidone in ethylene glycol to make small molecular weight polyvinylpyrrolidone-ethylene glycol solution and large molecular weight polyvinylpyrrolidone-ethylene glycol solution for subsequent use;

[0056] (3) silver nitrate is dissolved in the polyvinylpyrrolidone-ethylene glycol solution of small molecular weight at 5 ℃ to make silver nitrate-polyvinylpyrrolidone-ethylene glycol solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com