Material for photocuring three-dimensional manufacturing and application of material

A three-dimensional manufacturing and light-curing technology, applied in the direction of additive processing, can solve problems such as unsatisfactory, limited mechanical properties, and limit the development of three-dimensional manufacturing, and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] After mixing 30 parts by mass of urethane acrylate terminated by tert-butylaminoethyl methacrylate (TBAEMA), 30 parts by mass of thermoplastic polyurethane elastomer and 10 parts by mass of acrylate at high speed for 10 minutes, add 1-3 parts by mass The photoinitiator was stirred evenly.

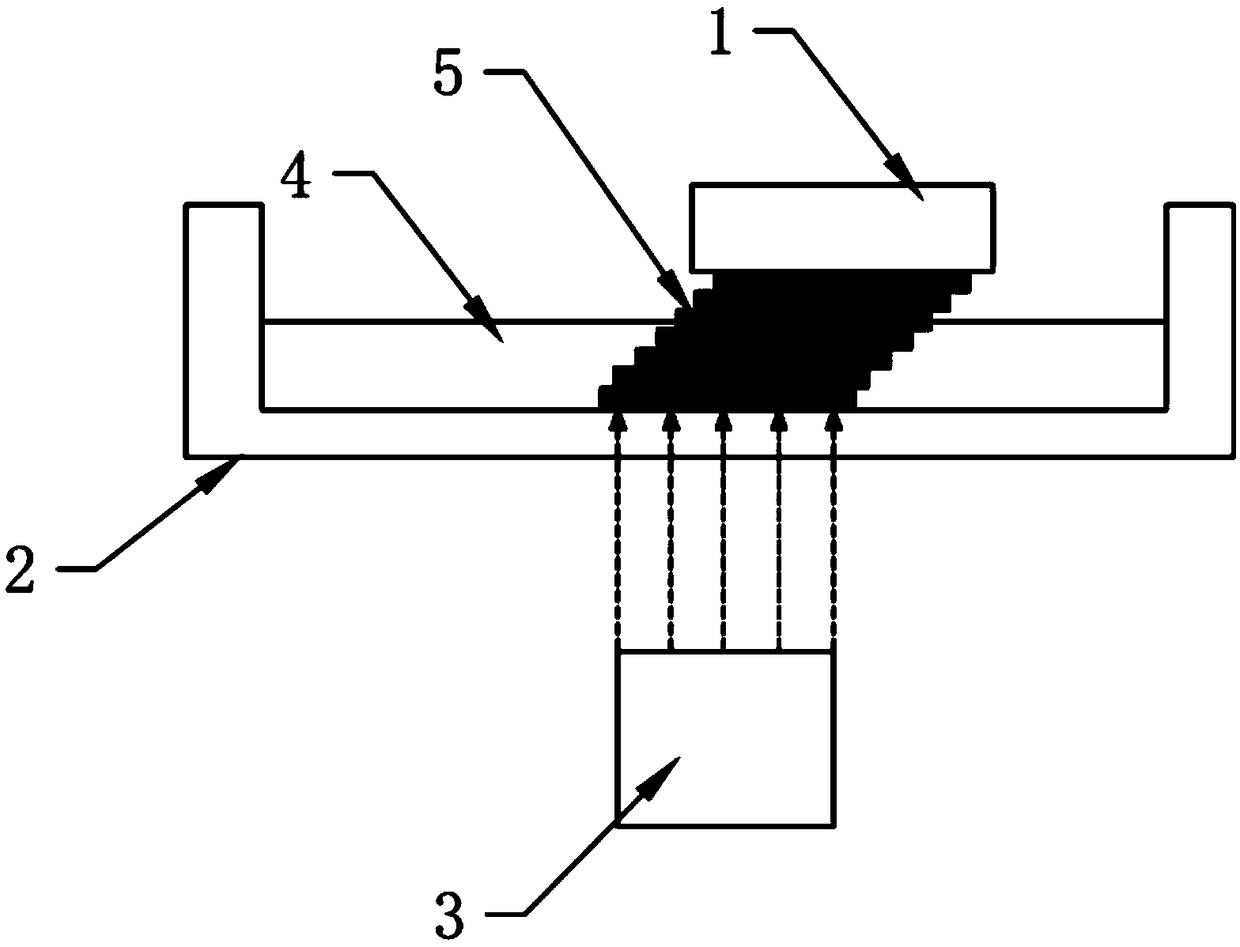

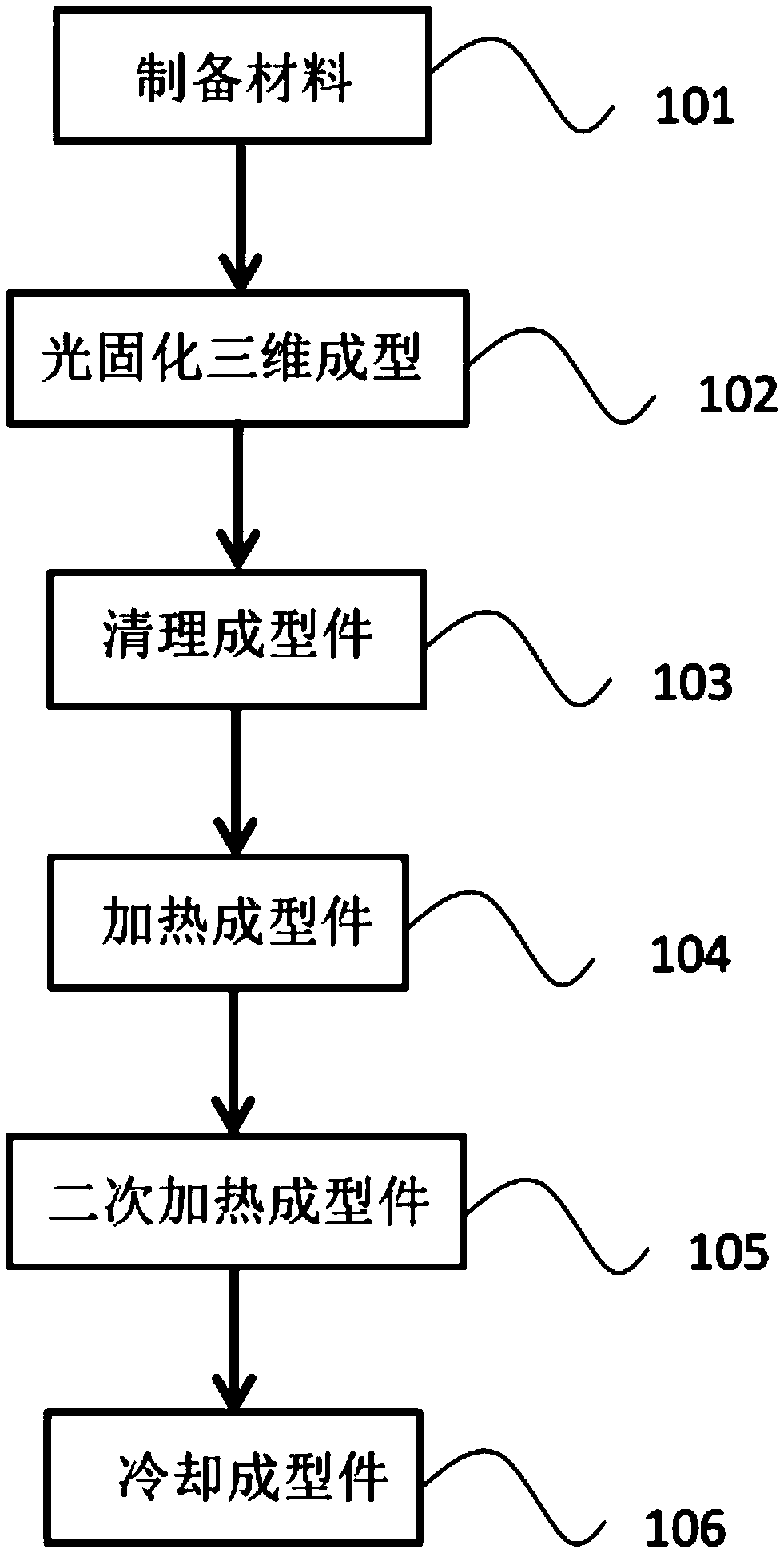

[0052] After mixing the above materials, use the light-curing three-dimensional molding equipment as described herein for three-dimensional molding. The three-dimensional molding can be a dog-bone-shaped spline, which is rinsed with alcohol solution and placed in a post-curing box for secondary curing. Carry out heat treatment at the same time of supplementary curing by light. In the first treatment stage, the heating temperature is 80°C, and the heating time is 50 minutes. Continue to the second treatment stage, and the heating temperature is 130°C, and the heating time is 100 minutes, and then the spline is cooled.

[0053] The mechanical properties of the sample were measured, and...

Embodiment 2

[0055] After mixing 25 parts by mass of polyurethane acrylate terminated by tert-butylaminoethyl methacrylate (TBAEMA), 35 parts by mass of thermoplastic polyurethane elastomer and 15 parts by mass of acrylate at high speed for 10 minutes, add 1-2 parts by mass The photoinitiator was stirred evenly.

[0056] After mixing the above materials, use the light-curing three-dimensional molding equipment as described herein for three-dimensional molding. The three-dimensional molding can be a dog-bone-shaped spline, which is rinsed with alcohol solution and placed in a post-curing box for secondary curing. Carry out heat treatment while supplementing curing with light. In the first treatment stage, the heating temperature is 100°C and the heating time is 50 minutes. Continue to the second treatment stage. The heating temperature is 160°C and the heating time is 100 minutes, and then the spline is cooled.

[0057] The mechanical properties of the sample were measured, and the average ...

Embodiment 3

[0059] After mixing 20 parts by mass of polyurethane acrylate terminated by tert-butylaminoethyl methacrylate (TBAEMA), 40 parts by mass of thermoplastic polyurethane elastomer and 20 parts by mass of acrylate at high speed for 10 minutes, add 0.5-2 parts by mass The photoinitiator was stirred evenly.

[0060] After mixing the above materials, use the light-curing three-dimensional molding equipment as described herein for three-dimensional molding. The three-dimensional molding can be a dog-bone-shaped spline, which is rinsed with alcohol solution and placed in a post-curing box for secondary curing. Carry out heat treatment while supplementing the curing with light. In the first treatment stage, the heating temperature is 100°C and the heating time is 60 minutes. Continue to the second treatment stage. The heating temperature is 180°C and the heating time is 150 minutes, and then the spline is cooled.

[0061] The mechanical properties of the sample were measured, and the av...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com