Construction method for green roof system

A construction method and roofing system technology, applied in the direction of roofing, roof covering, roof insulation materials, etc., can solve the problems of reducing service life, cracking, etc., and achieve the goal of improving the use environment, eliminating damage, good social benefits and environmental benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the drawings and specific embodiments, so that those skilled in the art can understand.

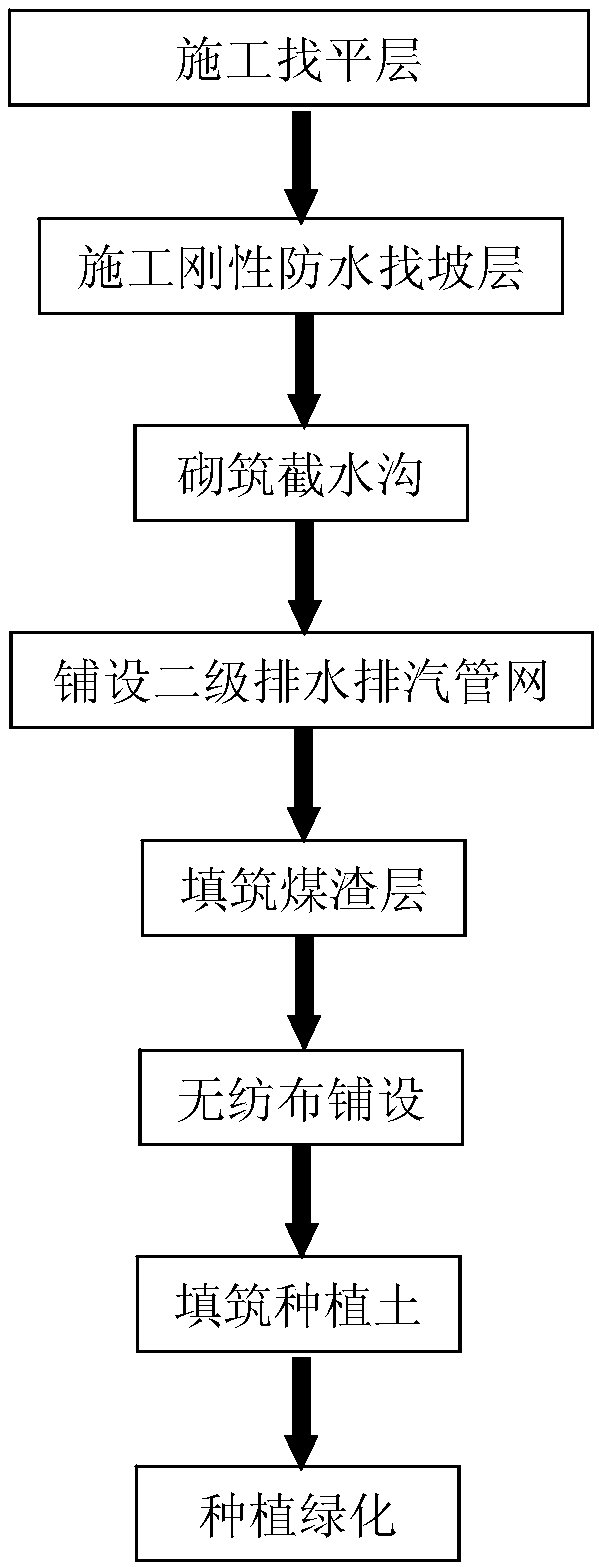

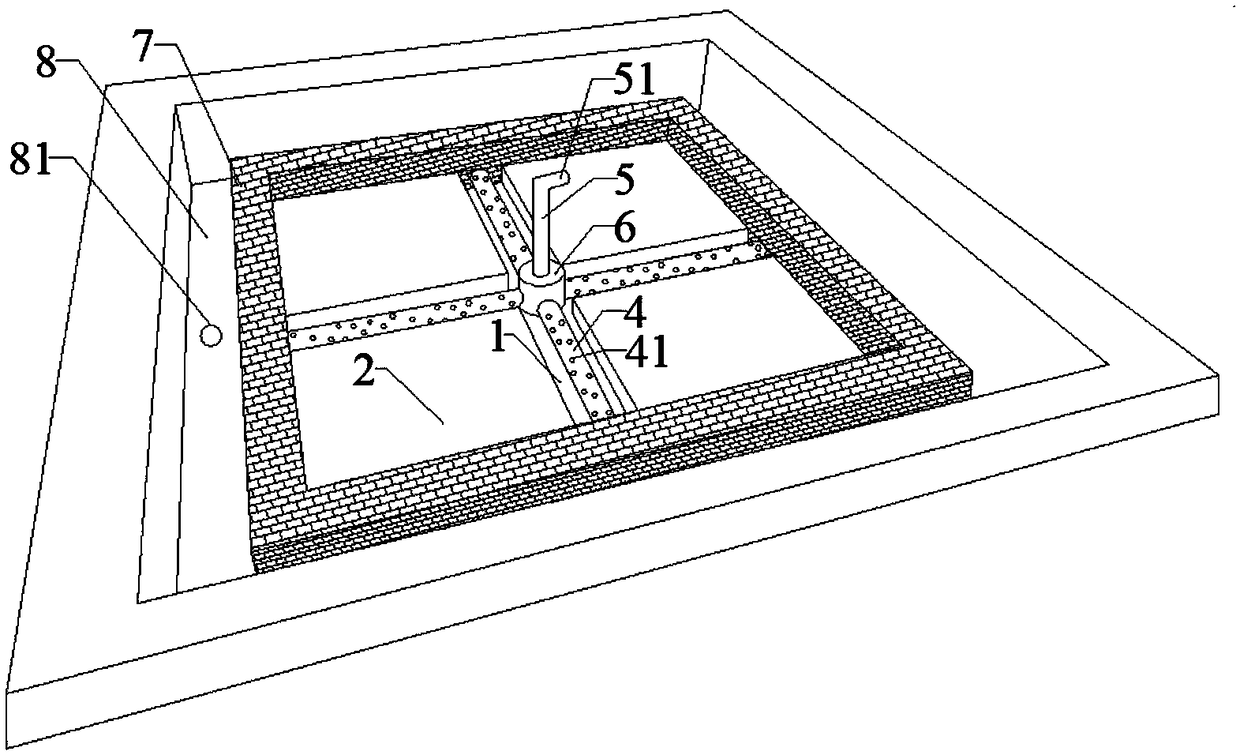

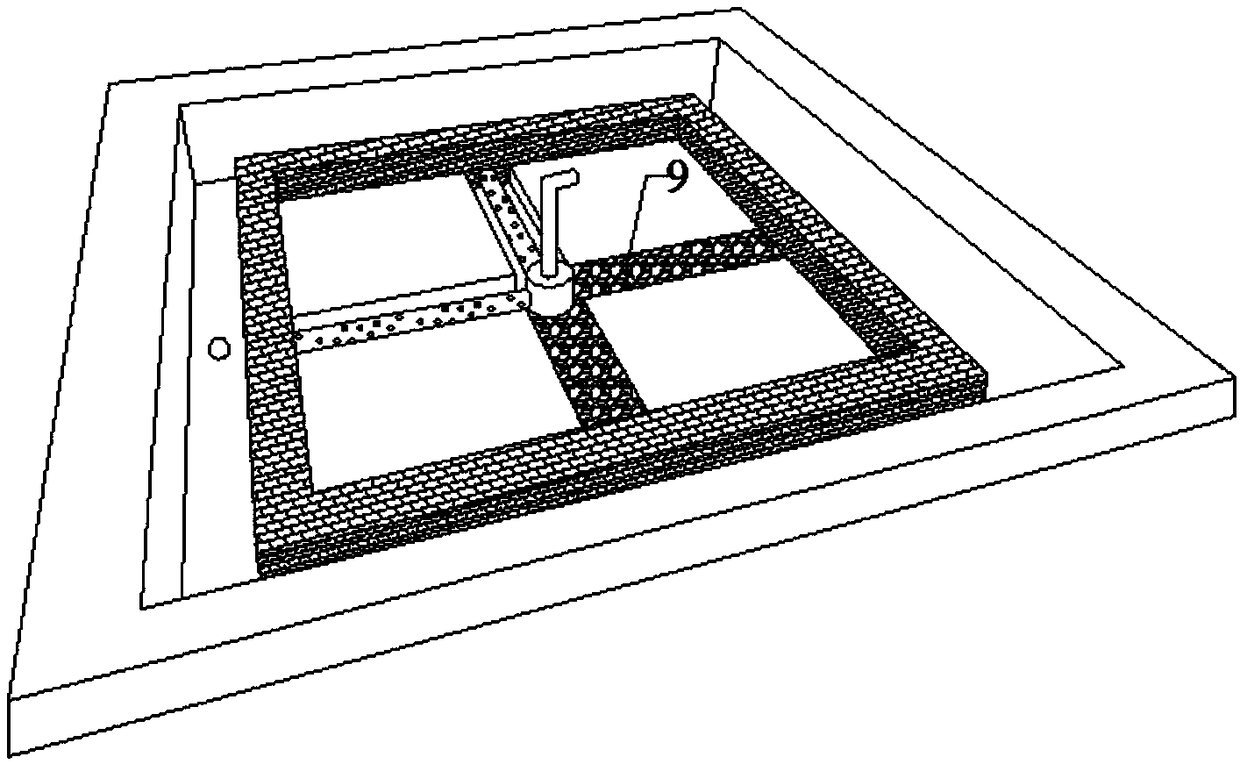

[0029] like figure 1 As shown, the construction method of the green roof system of the present invention, the construction method comprises the following steps: Step 1, constructing a leveling layer on the roof base; Step 2, constructing a rigid waterproof slope layer; , build a retaining wall around the parapet wall, the parapet wall and the retaining wall form an intercepting ditch, and a drainage hole is formed in the intercepting ditch, and the drainage hole is connected with the first-stage vertically downward drainage The drainage pipes are connected, and graded pebbles are filled in the intercepting ditch; Step 4, laying the secondary drainage and exhaust pipe network, first laying the secondary drainage pipes arranged horizontally and vertically, the horizontally arranged and vertically arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com