A Scissor Grab Self-lubricating Pulley Mechanism

A self-lubricating, pulley technology, applied in the direction of engine lubrication, mechanical equipment, engine components, etc., can solve problems such as affecting production efficiency and poor lubrication effect, and achieve low production costs, easy installation, and improved sealing performance and lubrication performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

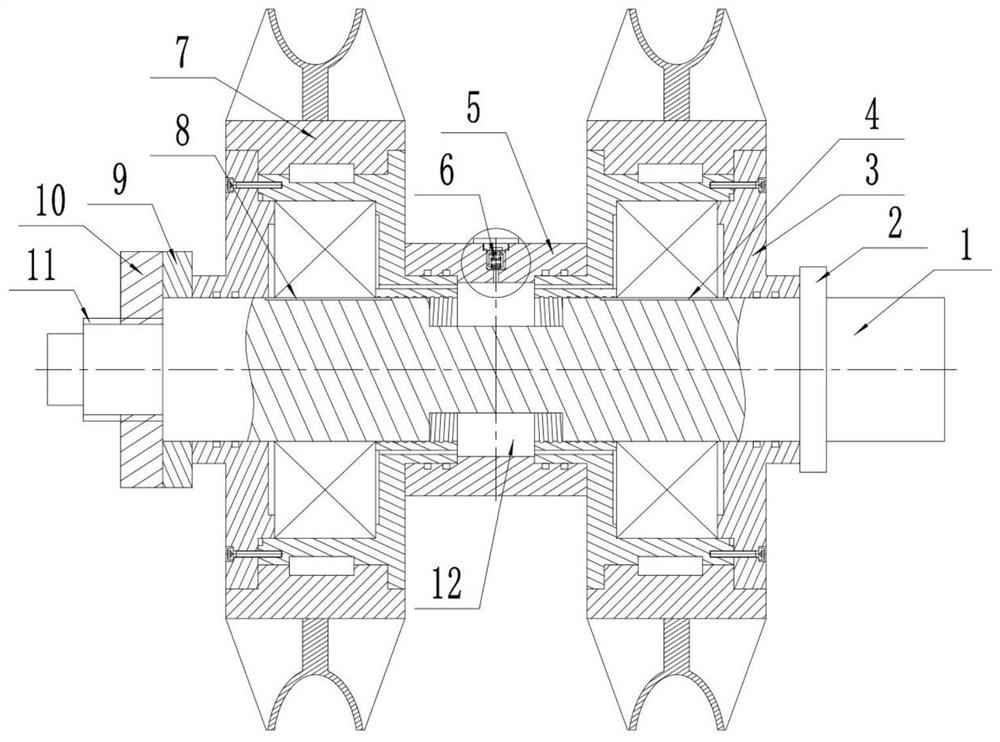

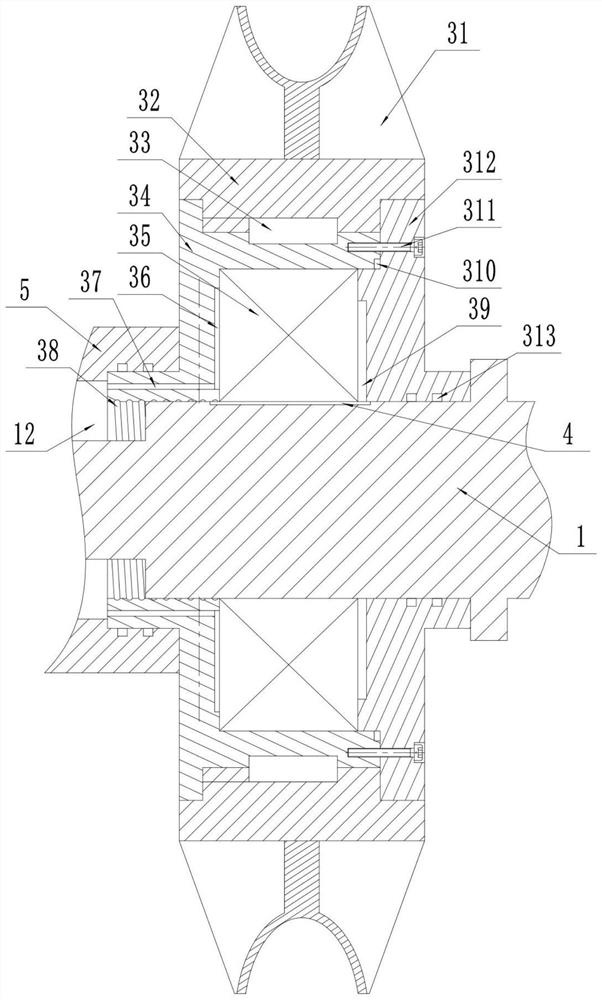

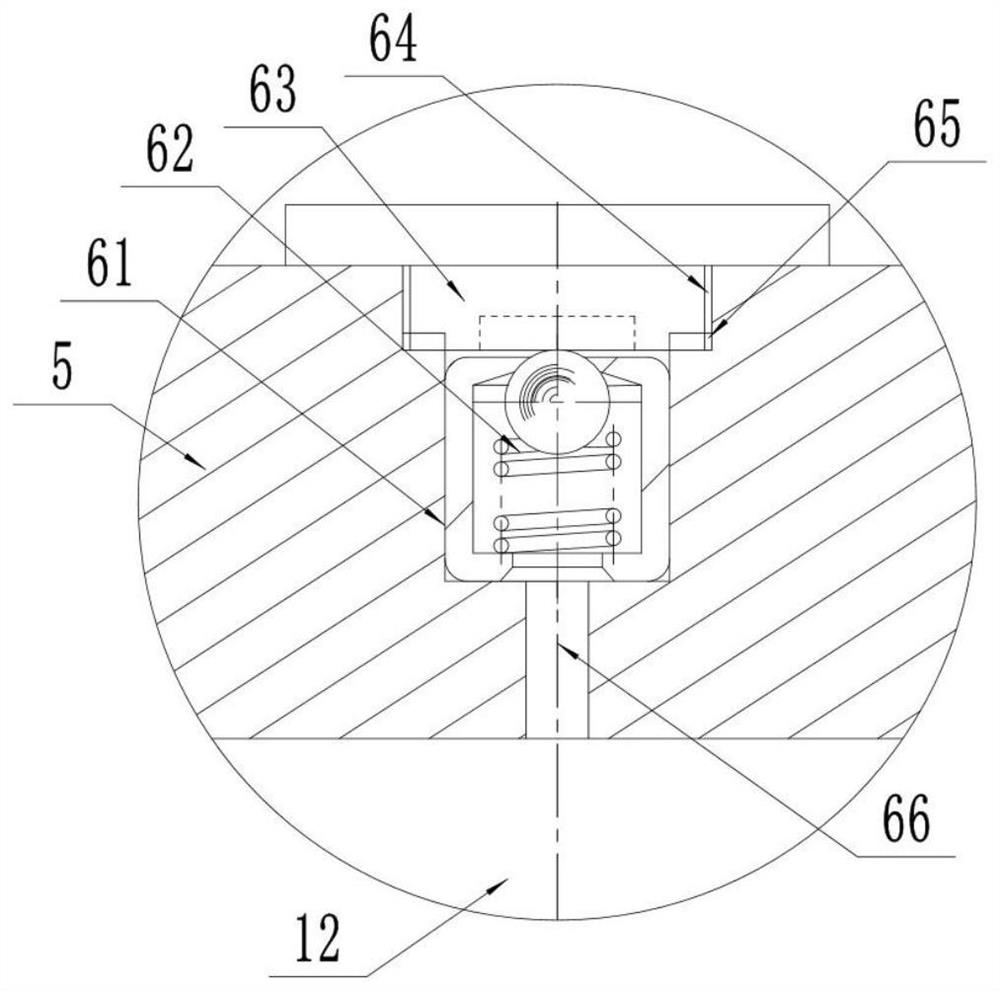

[0020] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a scissor grab bucket self-lubricating pulley mechanism, including a pulley shaft 1, and also includes a convex groove 2, a pulley block-3, a connecting groove-4, a connecting sleeve 5, and an oil filling port assembly 6. Pulley block 2 7, connecting groove 2 8, gasket 9, lock nut 10, external thread 11 and oil storage tank 12; the convex groove 2 is located outside the right side of the pulley shaft 1; the pulley block 1 3 is internally connected On the right side above the pulley shaft 1, the right end surface of the pulley block-3 is connected to the left side of the convex groove 2; the connecting groove-4 is located inside the pulley block-3, and the connecting groove-4 is horizontally arranged on the upper right side of the pulley shaft 1 In the outer circular surface; the right side of the connecting sleeve 5 is movably connected to the outer circular surface on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com