Anti-mite antibacterial non-woven medical mask

A technology of non-woven fabrics and masks, which is applied in the field of mask processing, can solve the problems of masks losing their protective properties, inability to kill germs, and damage to the respiratory system, so as to improve practicability and safety, reduce germ infection, and enhance air permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

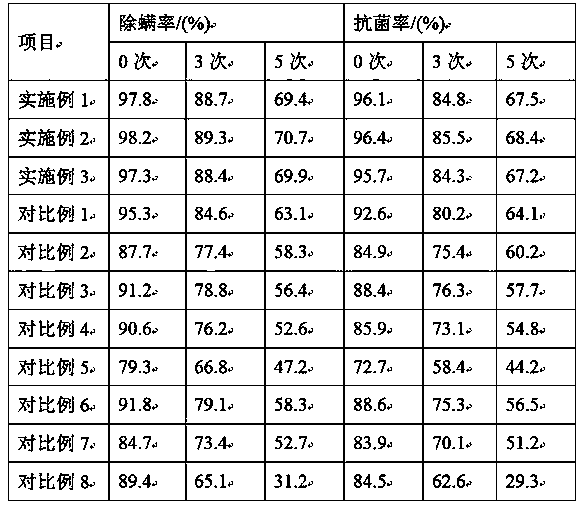

Embodiment 1

[0018] A mite-removing and antibacterial non-woven medical mask is made of the following raw materials in parts by weight: flax fiber 46, chitosan fiber 20, cotton fiber 15, cupro ammonia fiber 6, and Ag-polyurethane fiber 2.

[0019] For the Ag-polyurethane fiber, heat the polyurethane particles to fully melt, heat and stir for 10 minutes, then add pentaerythritol of 2% by weight of the polyurethane, heat and stir at 110r / min for 8 minutes to improve the flexibility of the polyurethane, and then add nano-silver while stirring , the addition amount is 0.5% of the polyurethane weight, adjust the vacuum to -57kPa, keep warm and stir for 20 minutes, improve the antibacterial and strength of polyurethane, make the mask more skin-friendly, enhance the antibacterial property, and avoid the simple effect of traditional masks on bacteria The filtering effect and the bacteria on the outer surface can enhance the protective effect of the mask on the human body. Melt spinning, the linear ...

Embodiment 2

[0026] A mite-removing and antibacterial non-woven medical mask is made of the following raw materials in parts by weight: flax fiber 47, chitosan fiber 21, cotton fiber 16, cupro ammonia fiber 7, and Ag-polyurethane fiber 3.

[0027] For the Ag-polyurethane fiber, heat the polyurethane particles to fully melt, heat and stir for 13 minutes, then add pentaerythritol with 2.5% of the weight of the polyurethane, heat and stir at 120r / min for 9 minutes to improve the flexibility of the polyurethane, and then add nano-silver while stirring , the addition amount is 0.6% of the weight of polyurethane, adjust the vacuum degree to -58kPa, keep warm and stir for 25 minutes, improve the antibacterial and strength of polyurethane, make the mask more skin-friendly, enhance the antibacterial property, and avoid the simple effect of traditional masks on bacteria The filtering effect on the outer surface and the bacterial growth on the outer surface enhance the protective effect of the mask on...

Embodiment 3

[0034] A mite-removing and antibacterial non-woven medical mask is made of the following raw materials in parts by weight: flax fiber 48, chitosan fiber 22, cotton fiber 17, cupro ammonia fiber 8, and Ag-polyurethane fiber 4.

[0035] For the Ag-polyurethane fiber, heat the polyurethane particles to fully melt, heat and stir for 15 minutes, then add 3% pentaerythritol by weight of the polyurethane, heat and stir at 130r / min for 10 minutes to improve the flexibility of the polyurethane, and then add nano-silver while stirring , the added amount is 0.7% of the polyurethane weight, adjust the vacuum to -59kPa, keep warm and stir for 30min, improve the antibacterial and strength of polyurethane, make the mask more skin-friendly, enhance the antibacterial property, and avoid the simple effect of traditional masks on bacteria The filtering effect and the bacteria on the outer surface can enhance the protective effect of the mask on the human body. Melt spinning, the linear density is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com