Demercuration catalyst for flue gas and preparation method and applications thereof

A catalyst and catalyst carrier technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of low surface activity of natural ore carriers, poor ability of modified ore to support transition metals, etc., and achieve improved adsorption. and binding capacity, increase the carboxyl active site, increase the effect of activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

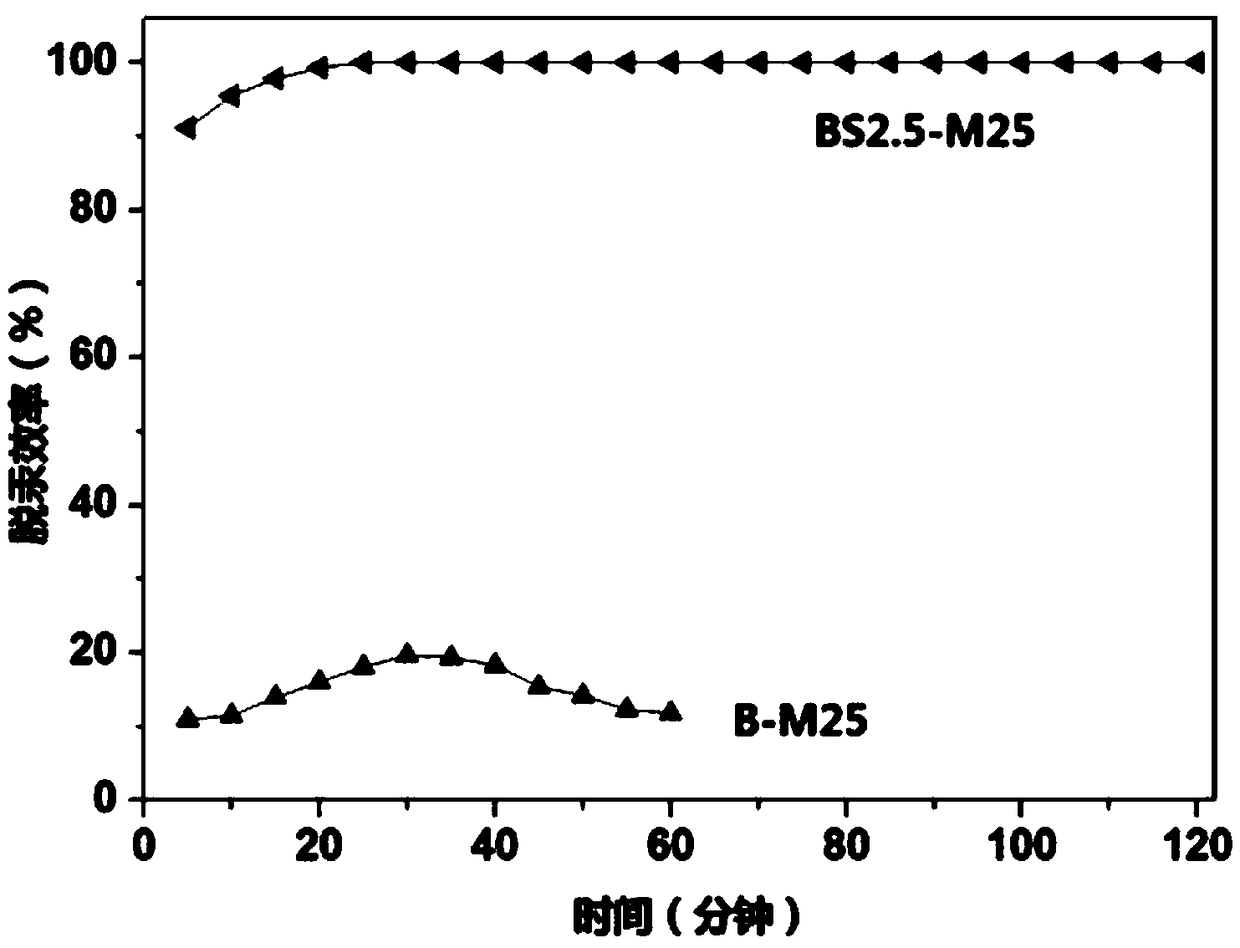

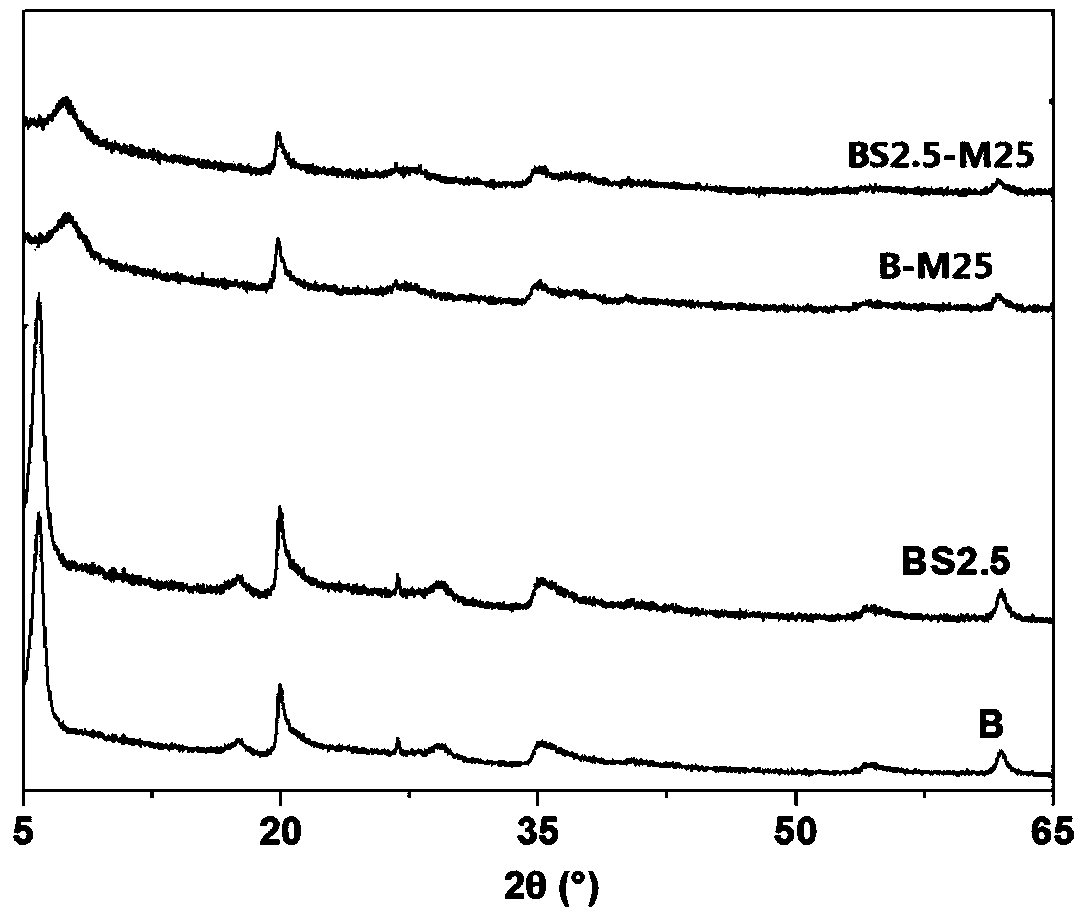

[0023] Example 1MnO x - Preparation of starch-bentonite (BS2.5-M25)

[0024] (1) Put 1.25g of cornstarch in a 200mL small beaker, slowly pour 100mL of 5% acetic acid solution to fully dissolve the starch, then add 50g of bentonite to the beaker, place it in a water bath at 45°C and stir for 10 hours. Then put the mixture on a small porcelain boat and dry it in an oven at 105°C for 24 hours to obtain a starch-bentonite composite (BS2.5).

[0025] (2) Pour 30mL of deionized water and 10mL of absolute ethanol into a 200mL small beaker, mix well, add 8g of starch-bentonite compound, stir until fully dissolved, then add 2g of KMnO4, continue to stir for 3h and let it stand for 12h, then mix the mixture Suction filtration was carried out, and the product after suction filtration was dried in an oven at 105° C. for 24 hours, and the finally obtained sample was recorded as MnOx-starch-bentonite.

[0026] (3) The sample is recorded as BS2.5-M25, where B is bentonite, S is starch, 2.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com