Full-automatic vertical type red punching equipment

A fully automatic, red punching technology, used in metal processing equipment, metal extrusion control equipment, sorting and other directions, can solve the problems of equipment requiring special personnel to operate, complex structure, and low control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

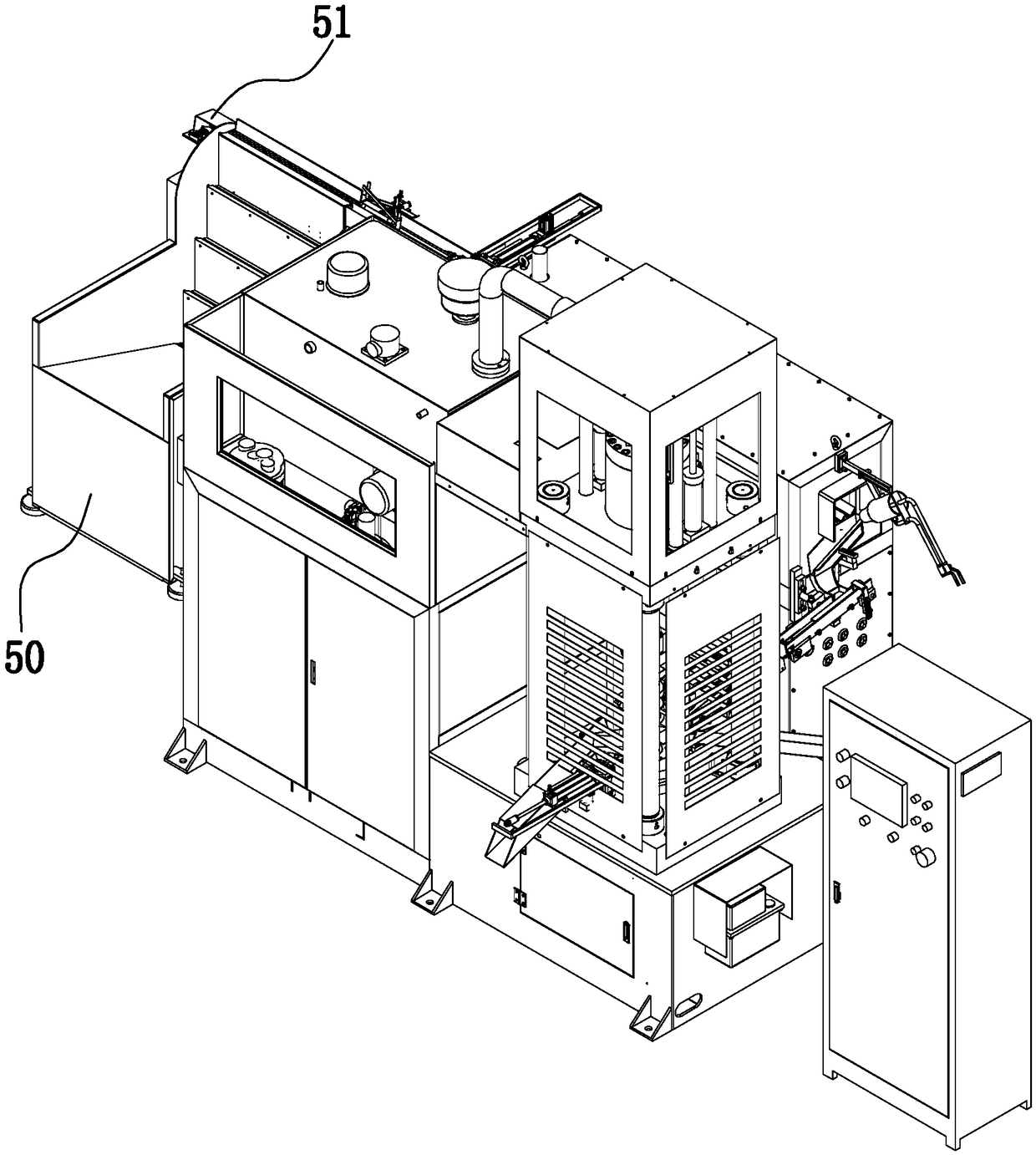

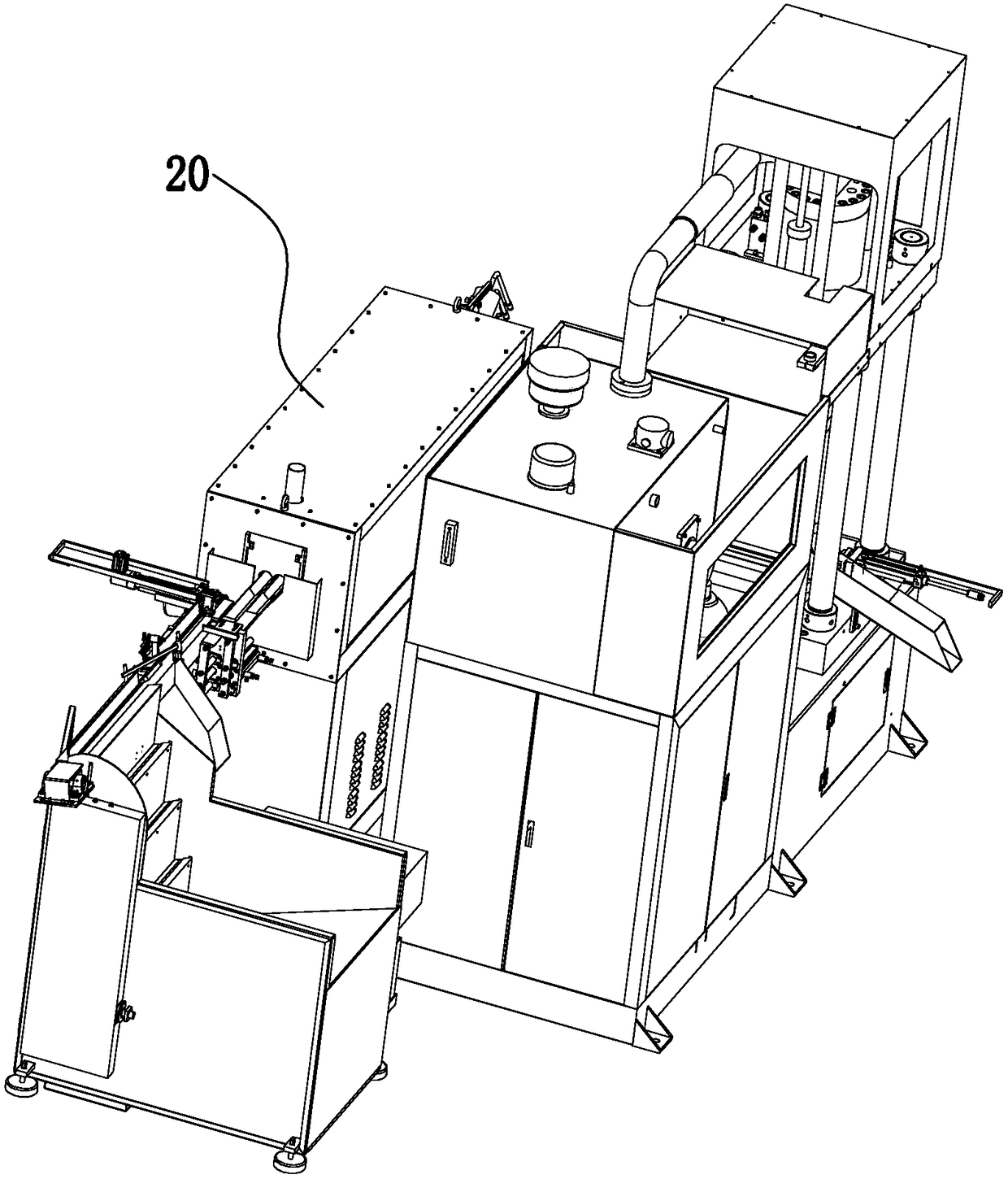

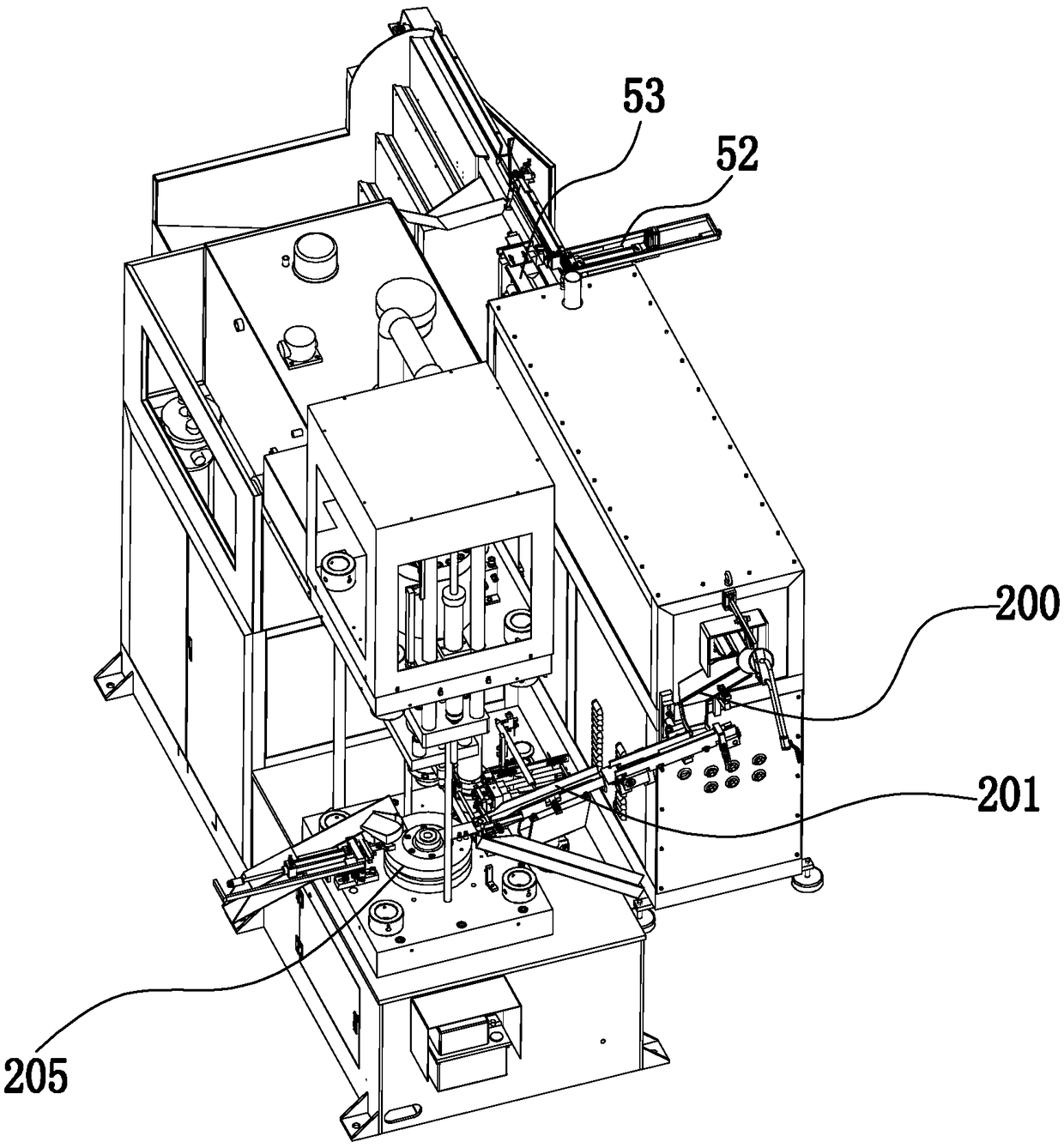

[0064] Example: such as Figure 1-3 As shown, a fully automatic vertical red punching equipment includes a loading frame assembly 50 for transferring workpieces, a raw material transmission device 51, a raw material pushing device 52 and a raw material feeding device 53; the raw material transmission device 51 is located on the upper The upper end of the material rack assembly 50; the position of the raw material pushing device 52 and the raw material feeding device 53 are corresponding; the raw material pushing device 52 and the raw material feeding device 53 are located at the end of the raw material transmission device 51; it is characterized in that: it also includes sequentially connected The red punch raw material heating furnace 20, the chute device 200, the conveying mechanism 201 and the processing mechanism 205; the raw material feeding device 53 is used to transport the workpiece to the red punch raw material heating furnace 20 for heating, and then transfer it to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com