Electric steering-by-wire system

A steering system and electric wire technology, applied in the direction of automatic steering control components, steering mechanisms, steering rods, etc., can solve the problem of hydraulic valves and oils with complex structure of the steering system, high operating noise, and steering performance that is easily affected by ambient temperature and pollution. The impact of the medium and other issues, to achieve the effect of simple maintenance, low operating noise, and convenient overall layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

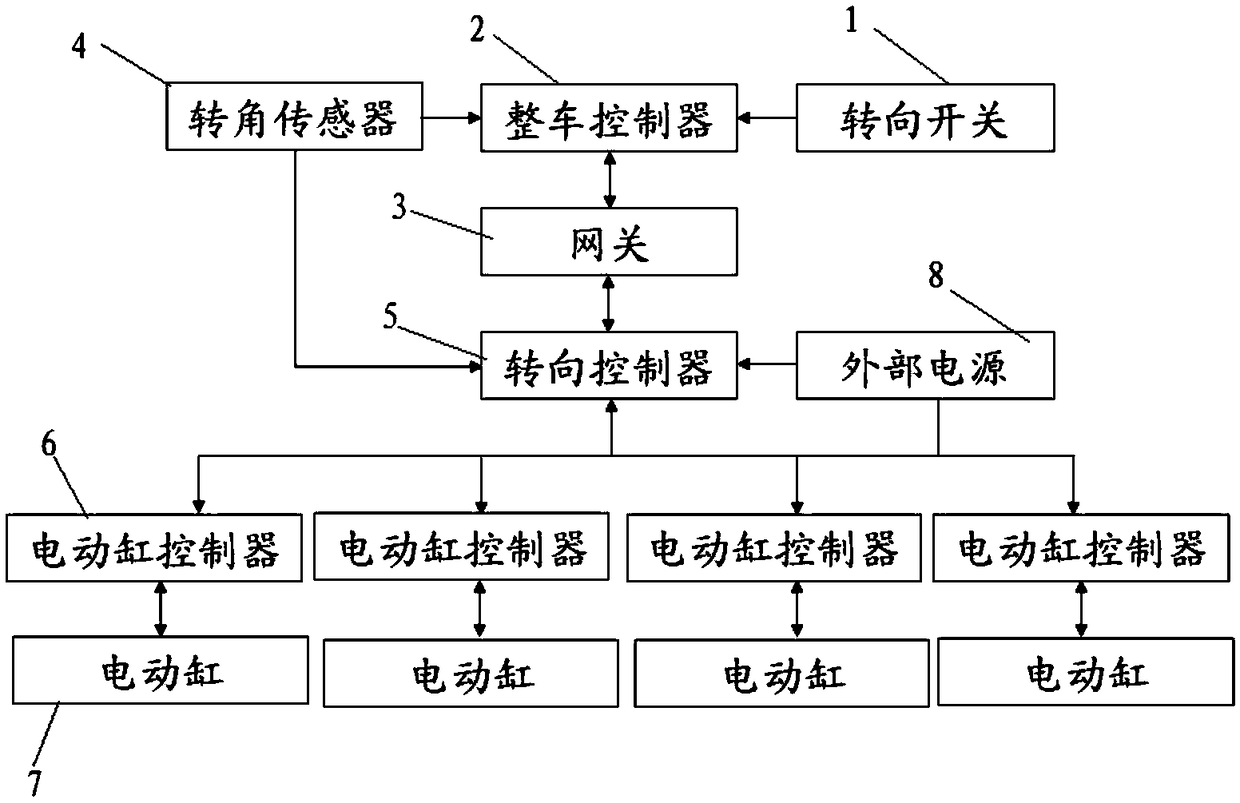

[0030] This embodiment provides an electric steering-by-wire system, which is applied to super-heavy off-road vehicles. Please refer to figure 1 , the steering system includes:

[0031] steering switch 1;

[0032] A vehicle controller 2, the vehicle controller 2 is communicatively connected to the steering switch 1, and the vehicle controller 2 receives and sends a vehicle speed signal and a signal that the steering switch 1 is turned on;

[0033] Specifically, the vehicle controller 2 is connected in communication with the steering switch 1, and the vehicle controller 2 receives the vehicle speed signal and the signal that the steering switch 1 is turned on, and further converts the above two signals to sent to the gateway 3.

[0034] A gateway 3, the gateway 3 receiving the vehicle speed signal sent by the vehicle controller 2 and the signal that the steering switch 1 is turned on;

[0035] Specifically, after the vehicle controller 2 receives the vehicle speed signal of ...

Embodiment 2

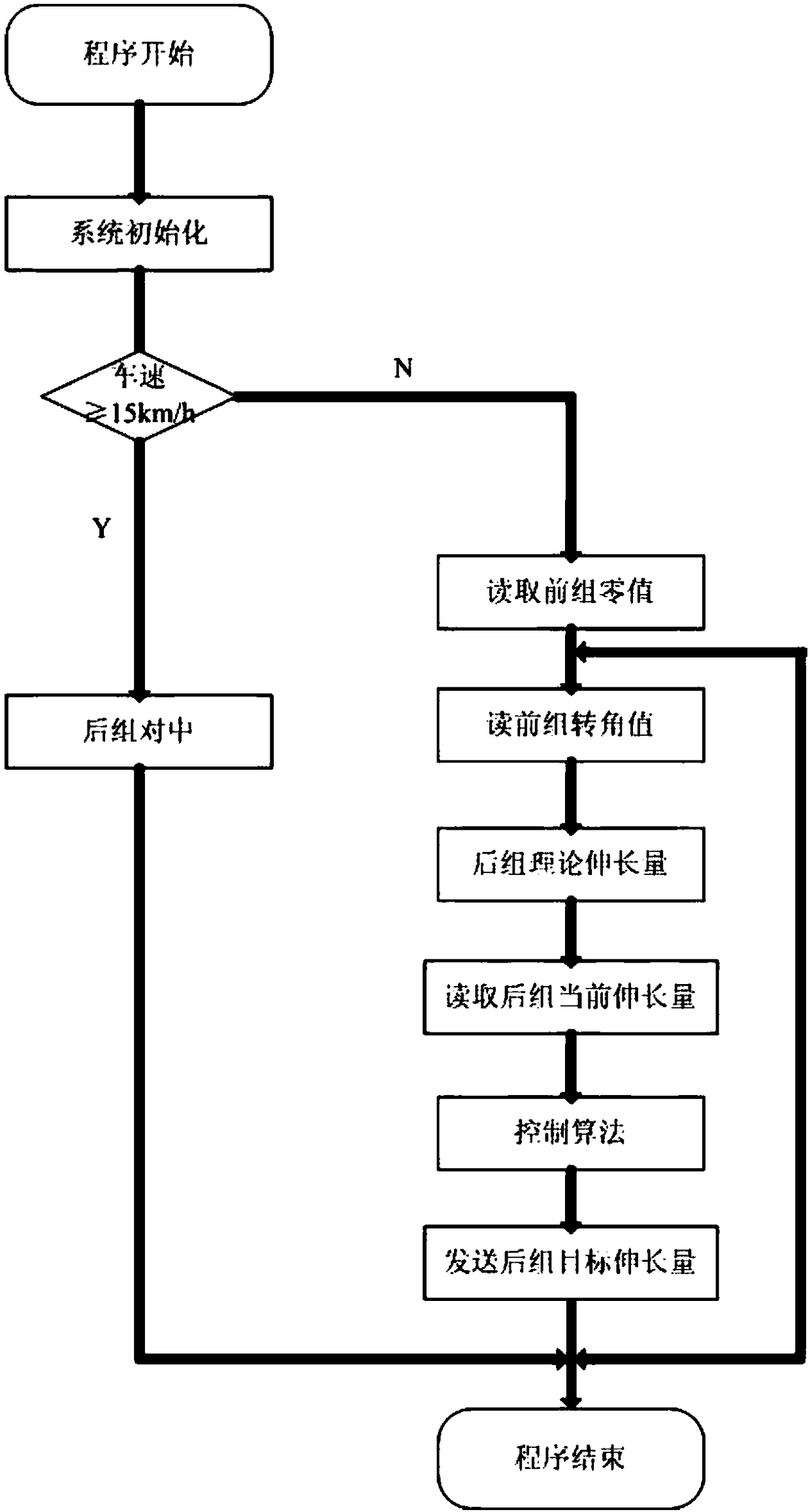

[0060] The working principle of an electric steering-by-wire system provided in this embodiment is described in detail below, specifically as follows:

[0061] After the program starts, the system is initialized; the vehicle speed signal is judged. If the vehicle speed exceeds the set value, the rear group alignment program is executed; if the vehicle speed does not exceed the set value, the steering program is executed; Value, read the corner value of the front group, calculate the theoretical elongation of the rear group, read the current elongation of the rear group, execute the control algorithm, and send the target elongation of the rear group, this process is a cyclic execution process; when the rear group When the target elongation is consistent with the theoretical elongation of the rear group, the steering program is executed and the program ends. Specifically, the vehicle controller 2 receives the vehicle speed signal and the signal that the rear steering switch is t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap