A low-energy microbial-electrochemical sewage treatment system

A sewage treatment system and sewage treatment method technology, applied in the field of water treatment, can solve the problems of high energy consumption, low treatment efficiency of refractory organic pollutants, high technical cost, etc., achieve low energy consumption, enhance wastewater treatment efficiency, and improve treatment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

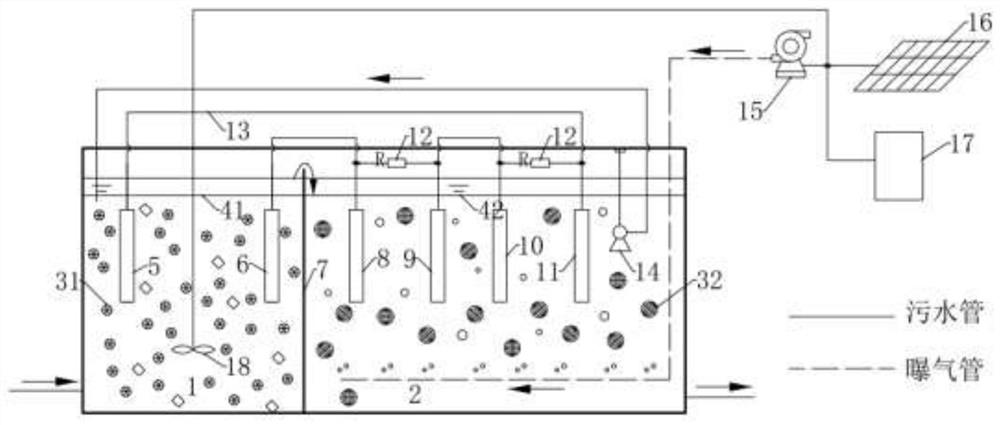

[0027] Such as figure 1The shown low-energy microbial-electrochemical sewage treatment system includes anoxic unit 1, aerobic unit 2, first packing 31, second packing 32, first screen 41, second screen 42, MEC Circuit, MFC circuit, separator 7, fixed value resistor 12, wire 13, mixed liquid return pump 14, aerator 15, solar panel 16, AC power supply 17, mixer 18; the first filler 31 is filled in the anoxic unit 1 Inside, the second packing 32 is filled in the aerobic unit 2, the first screen 41 is set at the first packing 31 close to the water surface, and the second screen 42 is set at the second packing 32 close to the water surface; the MEC circuit includes the MEC anode 5 and MEC cathode 6, MEC circuit embedded in anoxic unit 1, MFC circuit includes MFC circuit 1 and MFC circuit 2, MFC circuit 1 includes MFC1 cathode 8 and MFC1 anode 9, MFC2 includes cathode 10 and MFC2 anode 11, MFC circuit is embedded in aerobic Unit 2, the anoxic unit 1 and the aerobic unit 2 are separ...

Embodiment 2

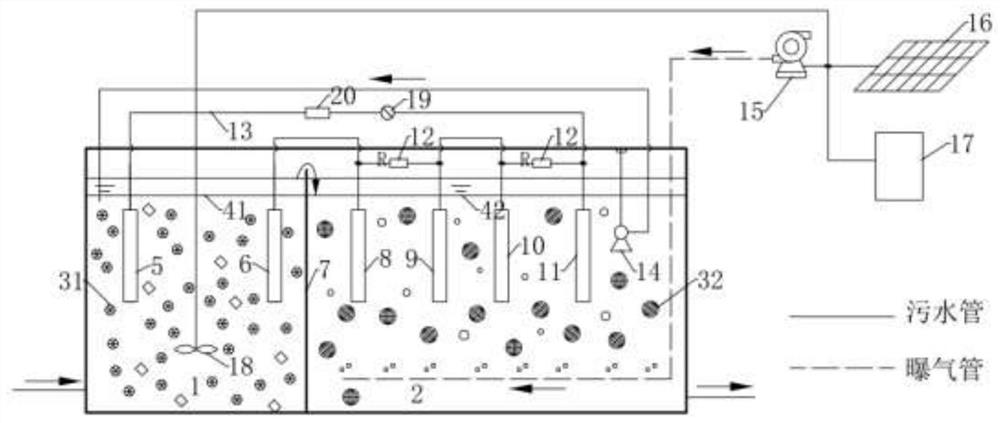

[0042] Such as figure 2 The shown low-energy microbial-electrochemical sewage treatment system includes anoxic unit 1, aerobic unit 2, first packing 31, second packing 32, first screen 41, second screen 42, MEC Circuit, MFC circuit, separator 7, fixed value resistor 12, wire 13, mixed liquid return pump 14, aerator 15, solar panel 16, AC power supply 17, mixer 18; the first filler 31 is filled in the anoxic unit 1 Inside, the second packing 32 is filled in the aerobic unit 2, the first screen 41 is set at the first packing 31 close to the water surface, and the second screen 42 is set at the second packing 32 close to the water surface; the MEC circuit includes the MEC anode 5 and MEC cathode 6, MEC circuit embedded in anoxic unit 1, MFC circuit includes MFC circuit 1 and MFC circuit 2, MFC circuit 1 includes MFC1 cathode 8 and MFC1 anode 9, MFC2 includes cathode 10 and MFC2 anode 11, MFC circuit is embedded in aerobic Unit 2, the anoxic unit 1 and the aerobic unit 2 are sep...

Embodiment 3

[0057] Such as figure 2 The shown low-energy microbial-electrochemical sewage treatment system includes anoxic unit 1, aerobic unit 2, first packing 31, second packing 32, first screen 41, second screen 42, MEC Circuit, MFC circuit, separator 7, fixed value resistor 12, wire 13, mixed liquid return pump 14, aerator 15, solar panel 16, AC power supply 17, mixer 18; the first filler 31 is filled in the anoxic unit 1 Inside, the second packing 32 is filled in the aerobic unit 2, the first screen 41 is set at the first packing 31 close to the water surface, and the second screen 42 is set at the second packing 32 close to the water surface; the MEC circuit includes the MEC anode 5 and MEC cathode 6, MEC circuit embedded in anoxic unit 1, MFC circuit includes MFC circuit 1 and MFC circuit 2, MFC circuit 1 includes MFC1 cathode 8 and MFC1 anode 9, MFC2 includes cathode 10 and MFC2 anode 11, MFC circuit is embedded in aerobic Unit 2, the anoxic unit 1 and the aerobic unit 2 are sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com