Water treatment dirt dispersion agent and preparation method thereof

A scale inhibitor and dispersant, water treatment technology, applied in water/sludge/sewage treatment, chemical instruments and methods, scale removal and water softening, etc. , to achieve the effect of improving the scale inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

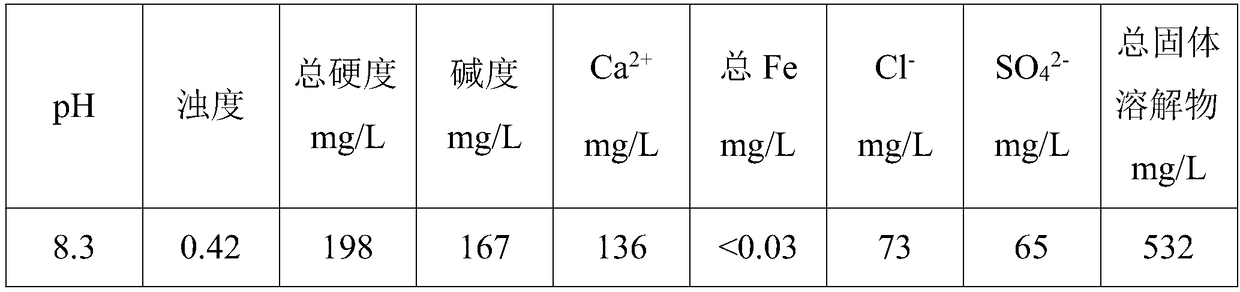

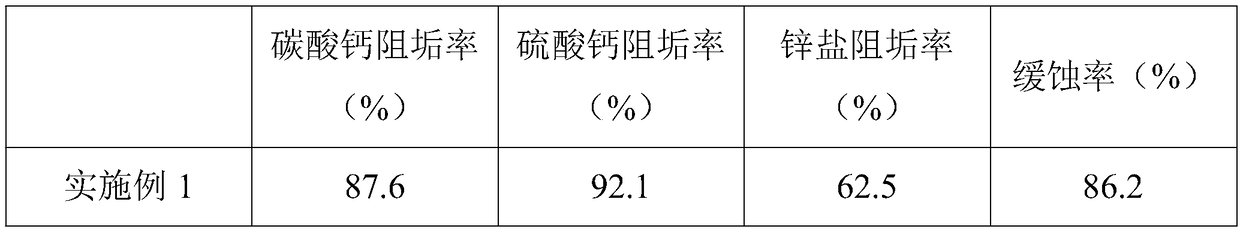

Embodiment 1

[0019] A water treatment antiscaling and dispersing agent, calculated in parts by weight, comprising the following raw materials:

[0020] 60 parts of maleic anhydride, 26 parts of allylsulfonic acid, 9 parts of aspartic acid, 24 parts of ethyl acrylate, 26 parts of mannose acid, 11 parts of initiator and 170 parts of water. The initiator is a mixture of ammonium persulfate and sodium bisulfite. The mass ratio of ammonium persulfate to the sodium bisulfite is 3:1.

[0021] The preparation method of scale inhibitor dispersant for water treatment comprises the following steps:

[0022] 1) Weighing maleic anhydride, allyl sulfonic acid, ethyl acrylate, mannose acid, initiator and water according to the proportioning ratio, first mixing maleic anhydride with part of the water and then stirring and dissolving to obtain an aqueous solution of maleic anhydride;

[0023] 2) dissolving the initiator in a small portion of water to prepare an aqueous initiator solution;

[0024] 3) Wa...

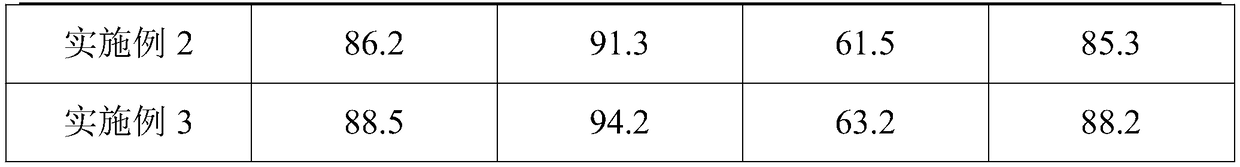

Embodiment 2

[0026] A water treatment antiscaling and dispersing agent, calculated in parts by weight, comprising the following raw materials:

[0027] 45 parts of maleic anhydride, 20 parts of allylsulfonic acid, 12 parts of aspartic acid, 30 parts of ethyl acrylate, 20 parts of mannose acid, 8 parts of initiator and 150 parts of water. The initiator is a mixture of ammonium persulfate and sodium bisulfite. The mass ratio of ammonium persulfate to the sodium bisulfite is 4:1.

[0028] The preparation method of scale inhibitor dispersant for water treatment comprises the following steps:

[0029] 1) Weighing maleic anhydride, allyl sulfonic acid, ethyl acrylate, mannose acid, initiator and water according to the proportioning ratio, first mixing maleic anhydride with part of the water and then stirring and dissolving to obtain an aqueous solution of maleic anhydride;

[0030] 2) dissolving the initiator in a small portion of water to prepare an aqueous initiator solution;

[0031] 3) Wa...

Embodiment 3

[0033] A water treatment antiscaling and dispersing agent, calculated in parts by weight, comprising the following raw materials:

[0034] 65 parts of maleic anhydride, 30 parts of allylsulfonic acid, 6 parts of aspartic acid, 20 parts of ethyl acrylate, 30 parts of mannose acid, 16 parts of initiator and 200 parts of water. The initiator is a mixture of ammonium persulfate and sodium bisulfite. The mass ratio of ammonium persulfate to the sodium bisulfite is 2:1.

[0035] The preparation method of scale inhibitor dispersant for water treatment comprises the following steps:

[0036] 1) Weigh maleic anhydride, allyl sulfonic acid, aspartic acid, ethyl acrylate, mannose acid, initiator and water according to the ratio for later use, first mix maleic anhydride with part of the water and stir to dissolve to obtain Aqueous solution of maleic anhydride;

[0037] 2) dissolving the initiator in a small portion of water to prepare an aqueous initiator solution;

[0038] 3) Raise t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com