Terpolymer concentration slow-release anti-sludging agent and method of preparation thereof

A technology of terpolymer and antiscalant, which is applied in chemical instruments and methods, descaling and water softening, and special treatment targets, etc., can solve problems such as hidden dangers of environmental pollution, eutrophication of water bodies, and short timeliness, and achieve Solve environmental pollution problems, improve scale inhibition performance, and have long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

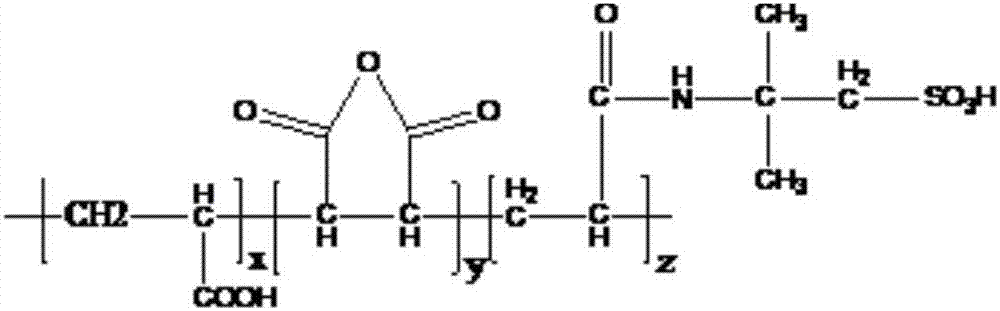

Method used

Image

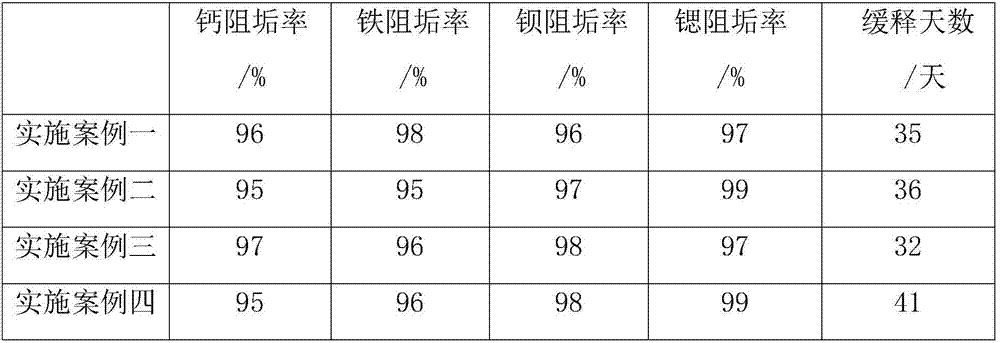

Examples

Embodiment 1

[0029] Step 1, 14.7g maleic anhydride is formulated into a 25% aqueous solution, 0.134g ferric ammonium sulfate is formulated into a 3% aqueous solution, the maleic anhydride is dissolved in water and poured into the reactor, and then the ferric ammonium sulfate aqueous solution is poured into the reactor , turn on the stirring to make it evenly mixed;

[0030] Step 2: Weigh 30% aqueous solution prepared by 0.224g of ammonium persulfate, then drop the ammonium persulfate solution and 3.6g of acrylic acid into the reactor at the same time, raise the temperature to 95°C, and start the reflux reaction for 1.5h;

[0031] Step 3: Weigh 4.14g of 2-acrylamide-2-methylpropanesulfonic acid to prepare a 30% aqueous solution, then slowly drop the solution into the reaction system of Step 2, and reflux at 95°C for 1 hour;

[0032] Step 4: Add 0.45 g of polyvinyl alcohol to the reaction system in Step 3, stir to dissolve, then concentrate and dry to obtain a terpolymer concentrated scale i...

Embodiment 2

[0035] Step 1, 29.4g maleic anhydride is formulated into a 50% aqueous solution, 0.387g ferric ammonium sulfate is formulated into a 10% aqueous solution, the maleic anhydride is dissolved in water and poured into the reactor, and then the ferric ammonium sulfate aqueous solution is poured into the reactor , turn on the stirring to make it evenly mixed;

[0036] Step 2: Weigh 60% aqueous solution prepared by 6.45g of ammonium persulfate, then drop the ammonium persulfate solution and 14.4g of acrylic acid into the reactor at the same time, raise the temperature to 50°C, and start the reflux reaction for 5h;

[0037] Step 3: Weigh 20.7g of 2-acrylamide-2-methylpropanesulfonic acid to prepare a 30% aqueous solution, then slowly drop the solution into the reaction system of Step 2, and react under reflux at 50°C for 4h;

[0038] Step 4: Add 3.225 g of polyvinyl alcohol to the reaction system in Step 3, stir to dissolve, then concentrate and dry to obtain a terpolymer concentrated...

Embodiment 3

[0041] Step 1, 22.0g maleic anhydride is formulated into a 40% aqueous solution, 0.260g ferric ammonium sulfate is formulated into a 6% aqueous solution, the maleic anhydride is dissolved in water and poured into the reactor, and then the ferric ammonium sulfate aqueous solution is poured into the reactor , turn on the stirring to make it evenly mixed;

[0042] Step 2, weigh 3.22g of ammonium persulfate to prepare a 45% aqueous solution, then drop the ammonium persulfate solution and 9.0g of acrylic acid into the reactor at the same time, raise the temperature to 70°C, and start the reflux reaction for 2.5h;

[0043] Step 3: Weigh 10.12g of 2-acrylamide-2-methylpropanesulfonic acid to prepare a 40% aqueous solution, then slowly drop the solution into the reaction system of Step 2, and reflux at 70°C for 1 hour;

[0044] Step 4: Add 1.45 g of polyvinyl alcohol to the reaction system in Step 3, stir to dissolve, then concentrate and dry to obtain a terpolymer concentrated scale ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com