Up-to-standard discharging system of slag-washing water from thermal power plant based on water balance

A technology of discharge system and thermal power plant, applied in water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as impurity enrichment, achieve balance of water supply and drainage, and solve impurity enrichment , The effect of reducing the cost of water and drainage in thermal power plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

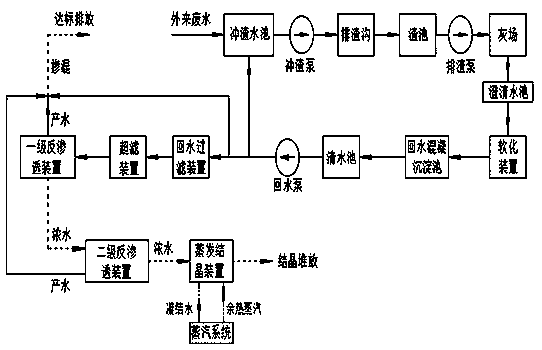

[0007] The slag flushing water discharge system of the thermal power plant based on water balance in the present invention has a slag flushing pool, and the output of the slag flushing pool sequentially passes through the slag flushing pump, slag discharge ditch, slag pool, slag discharge pump, ash yard, clarification pool, The softening device, return water coagulation sedimentation tank, clear water tank and return water pump return to the slag flushing pool; the return water pump also has one path directly connected to the water production end of the first-stage reverse osmosis device, and the other path passes through the return water filter device, ultra- The filtering device is connected to the input end of the primary reverse osmosis device; the concentrated water end of the primary reverse osmosis device is connected to the secondary reverse osmosis device, and the water production end of the secondary reverse osmosis device is connected to the primary reverse osmosis de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com