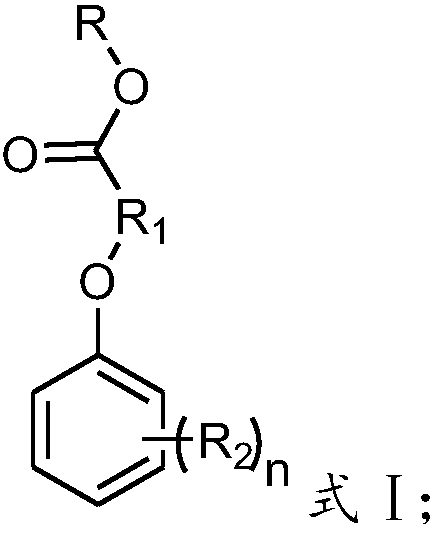

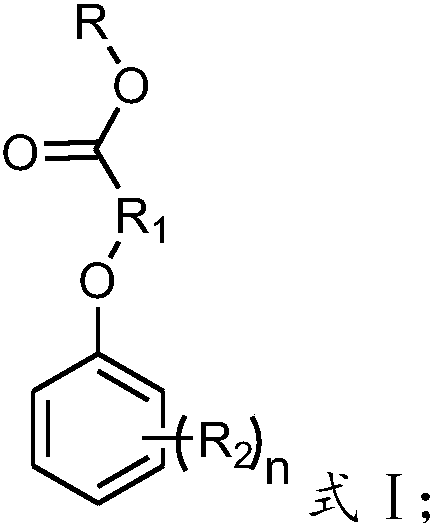

Preparation method of chlorophenoxycarboxylic acid herbicide

A technology of chlorophenoxycarboxylic acid and chlorophenoxycarboxylic acid ester, which is applied in the direction of carboxylate/lactone preparation, herbicides and algicides, botany equipment and methods, etc., and can solve the problems affecting chlorophenoxycarboxylic acid The production and application of similar compounds, difficult recovery of catalysts, high processing costs, etc., achieve the effects of easy separation, thorough reaction, and increased reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Mix and stir 100g of methyl 2,4-dichlorophenoxyacetate with a mass fraction of 99%, 100g of 30% hydrochloric acid, and 5g of p-toluenesulfonic acid, raise the temperature to 120°C, react for 2 hours, let stand to separate layers, and separate the water phase Applying the same method to the next batch, the temperature of the oil phase was lowered to obtain solid 2,4-dichlorophenoxyacetic acid, which was dried to obtain 93.1 g of 2,4-dichlorophenoxyacetic acid with a purity of 99.6% and a yield of 99.6%.

Embodiment 2

[0039] Mix 100g of methyl 2-methyl-4-chlorophenoxyacetate with a mass fraction of 99%, 120g of 30% hydrochloric acid, and 8g of dodecylbenzenesulfonic acid, mix and stir, heat up to 150°C, react for 1.5h, and stand to separate layers , the water phase was separated and applied to the next batch, the oil phase was cooled to obtain 2-methyl-4-chlorophenoxyacetic acid solid, and dried to obtain 92.3g of 2-methyl-4-chlorophenoxyacetic acid with a purity of 99.3%. Rate 99.0%.

Embodiment 3

[0041] Mix and stir 100g of methyl 2,4-dichlorophenoxyacetate with a mass fraction of 99%, 150g of 30% hydrochloric acid, and 10g of dodecylbenzenesulfonic acid, heat up to 160°C, react for 1.0h, and let the The water phase was separated and applied to the next batch, and the oil phase was cooled to obtain solid 2,4-dichlorophenoxyacetic acid, which was dried to obtain 93.0 g of 2,4-dichlorophenoxyacetic acid with a purity of 99.7% and a yield of 99.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com