Coffee-flavor heating-incombustible cigarette sheet additive and preparation method and use thereof

A heat-not-burn, additive technology, applied in the field of tobacco, can solve the problems of unstable chemical properties, uneven aroma release, oxidative deterioration, etc., and achieve the effects of rich aroma, low cost, and reduced irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

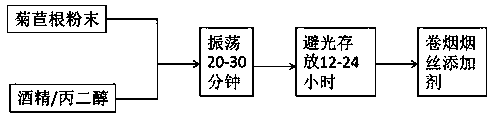

[0018] Pipette 10% mass percentage of crushed chicory root powder, 90% volume concentration 60% (or 70%, 80%, or 90%) alcohol and mix, shake at room temperature for 20 minutes to fully dissolve the raw materials, and prepare the The homogeneous solution is filled into barrels, placed in a dark and cool place, and stored for 12 hours to obtain the heat-not-burn cigarette sheet additive.

[0019] The heat-not-burn cigarette sheet additive was sprayed on the surface of the heat-not-burn cigarette sheet at an amount of 1.0 mL / 100 grams, and the heat-not-burn cigarette sample was rolled with Hongtashan (classic 100) leaves, and the rest of the auxiliary materials and additives were Keeping the same, heat-not-burn cigarette sample A was prepared, compared with Hongtashan (Classic 100) products, and found that: the aroma quality increased by 4%, the irritation decreased by 3%, the coffee aroma increased by 2%, and it has a better smoking quality. Suction consistency.

Embodiment 2

[0021] Pipette 15% mass percent of the crushed chicory root powder and 85% propylene glycol to mix, shake at room temperature for 25 minutes to fully dissolve the raw materials, prepare a homogeneous solution, put it in a bucket, place it in a dark and cool place, and store it for 24 hours. hours, the heat-not-burn cigarette sheet additive was obtained.

[0022] The heat-not-burn cigarette sheet additive was sprayed on the surface of the heat-not-burn cigarette sheet at an amount of 3.0mL / 100g sheet, and the heat-not-burn cigarette sample was rolled with Hongtashan (classic 100) leaves, and the rest of the auxiliary materials and additives were Keeping the same, heat-not-burn cigarette sample B was prepared, compared with Hongtashan (classic 100) products, and found that the richness of aroma increased by 4%, the irritation decreased by 6%, and the aroma of coffee increased by 4%. Consistency of suction.

Embodiment 3

[0024] Pipette 20% mass percentage of crushed chicory root powder and mix with 80% alcohol or propylene glycol, shake at room temperature for 30 minutes to fully dissolve the raw materials, prepare a uniform solution, put it in a bucket, and place it in a dark and cool place. After storing for 18 hours, the heat-not-burn cigarette sheet additive is obtained.

[0025] The heat-not-burn cigarette sheet additive was sprayed on the surface of the heat-not-burn cigarette sheet at an amount of 5.0mL / 100g sheet, and the heat-not-burn cigarette sample was rolled with Hongtashan (classic 100) leaves, and the rest of the auxiliary materials and additives were Keeping the same, the heat-not-burn cigarette sample C was prepared, compared with Hongtashan (Classic 100) products, it was found that the richness of aroma increased by 5%, the irritation decreased by 5%, and the aroma of coffee increased by 8%. Consistency of suction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com