Functional handmade soap and preparation method thereof

A functional, handmade soap technology, applied in the field of daily washing and beauty products, can solve the problems of incomplete composition, inconspicuous functional effect, process difference, etc., and achieve the effect of improving various related problems, high quality and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] This example describes the composition of a functional handmade soap of the present invention and a manufacturing method of the handmade soap.

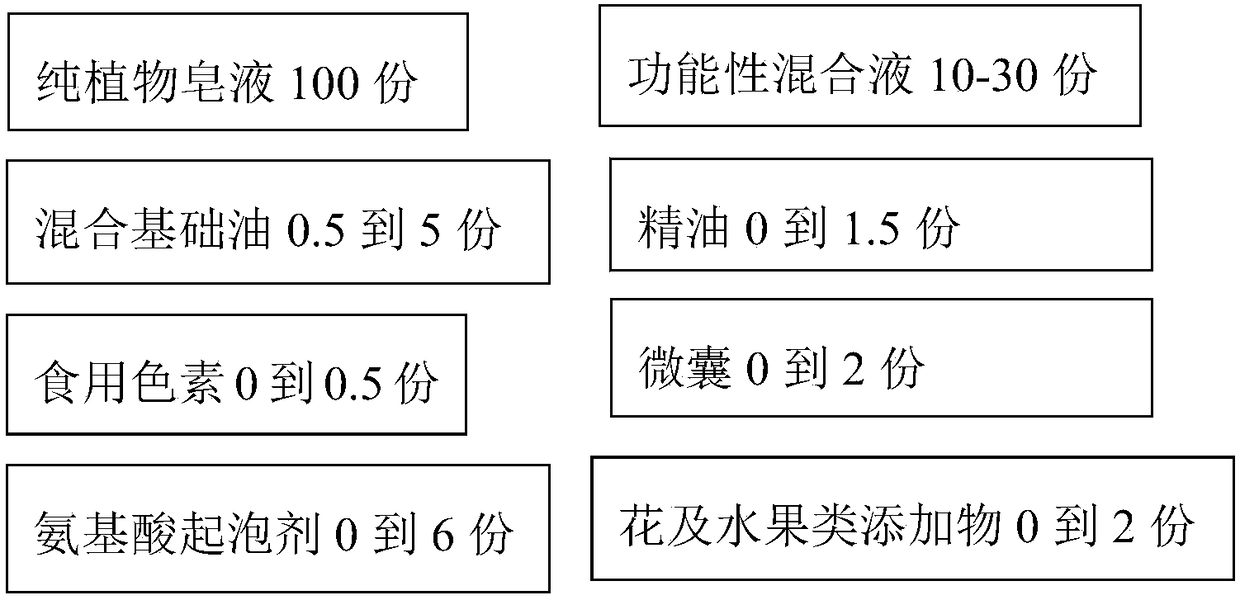

[0073] A kind of functional handmade soap, its composition is as follows figure 1 shown. From figure 1 It can be seen that it is made of the following raw materials by weight: 100 parts of pure vegetable soap base, 10-30 parts of functional mixed liquid, 0.5 to 5 parts of mixed base oil, 0 to 1.5 parts of essential oil, 0 to 0.5 parts of food coloring, 0 to 2 parts of microcapsules, 0 to 6 parts of amino acid foaming agent and 0 to 2 parts of flower and fruit additives.

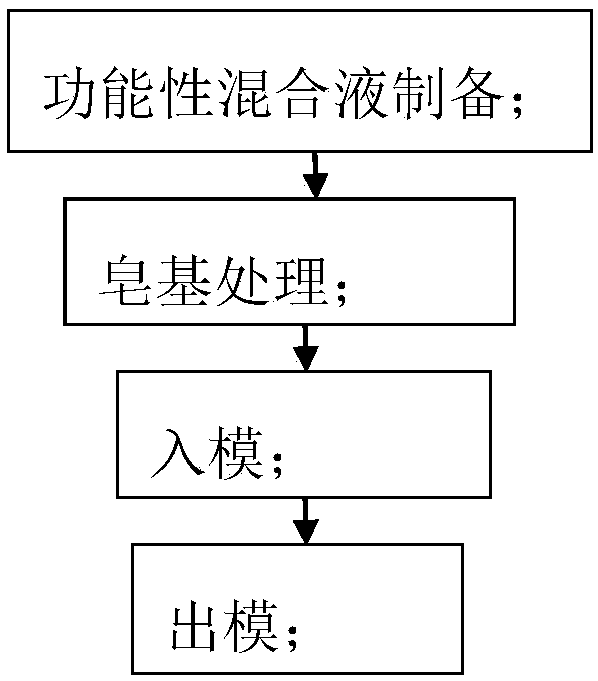

[0074] A kind of making method of handmade soap, such as figure 2 shown. From figure 2 As can be seen, a kind of preparation method of handmade soap comprises the steps:

[0075] Step 1, preparation of functional mixture;

[0076] Step 2, soap base treatment;

[0077] Step 3, enter the mold;

[0078] Step 4, release the mold.

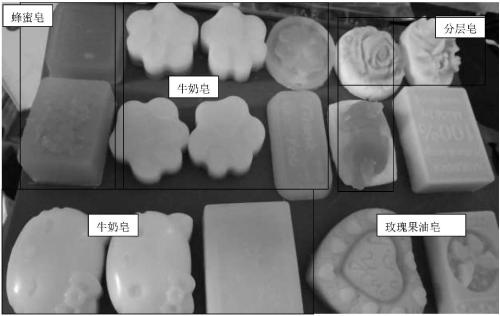

[0079] Various handm...

Embodiment 2

[0081] This example describes the preparation of functional milk soap according to the composition and method of the present invention. Specifically:

[0082] The functional mixture for making milk soap includes 3 to 7 parts of pure dew; 20-25 parts of milk; 0-2 parts of honey; 1 part of egg white; 0 to 0.5 parts of brown sugar; 2-4 parts of foaming agent; 0 to 0.5 parts of plant antibacterial agent; 0 to 1 part of dried flowers and others;

[0083] Among them, milk can be replaced by the same amount of breast milk or goat milk; pure dew can also be replaced by purified water or moxa water; the main function of brown sugar is to deeply moisturize and nourish the skin. If it is for sensitive and oily skin, it can be added less or not. Add more, dry skin can add more; if the pure dew is replaced by moxa water, the plant antibacterial agent can be added less or not;

[0084] According to the user's preference, pigments or various single or compound essential oils can be added t...

Embodiment 3

[0096] The present embodiment narrates and prepares freckle-removing soap according to composition and method described in the present invention, specifically:

[0097] The functional mixture used to make freckle soap includes 3 parts of pure dew; 6 parts of Angelica root solution; 3 parts of distilled water; 15 parts of milk; 2 parts of honey; 0.5 parts; 1 part of egg white powder; among them, silk protein powder, seven seed white powder, pearl powder, aloe vera powder and egg white powder should have a particle size larger than 150,000 mesh or a particle diameter smaller than 100 nanometers;

[0098] Among them, 3 parts of distilled water and 3 parts of pure dew and 1 part of egg white powder can also be removed, and replaced with 6.5 parts of egg white and 0.5 parts of plant antibacterial agent;

[0099] Among them, the milk can be replaced by the same amount of breast milk or goat milk; the pure dew can also be replaced by pure water or moxa water; Add or not; according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com