Anti-corrosion coating natural environment test and performance detecting system

A natural environment, anti-corrosion coating technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as labor-intensive and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

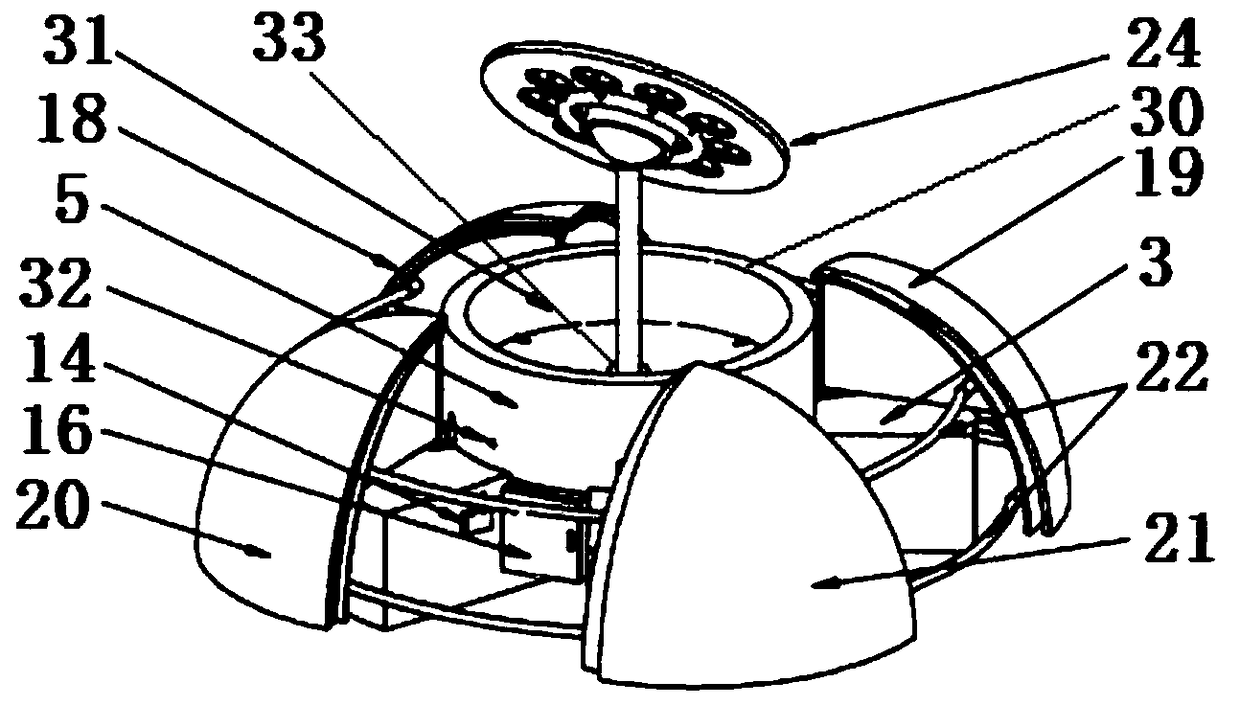

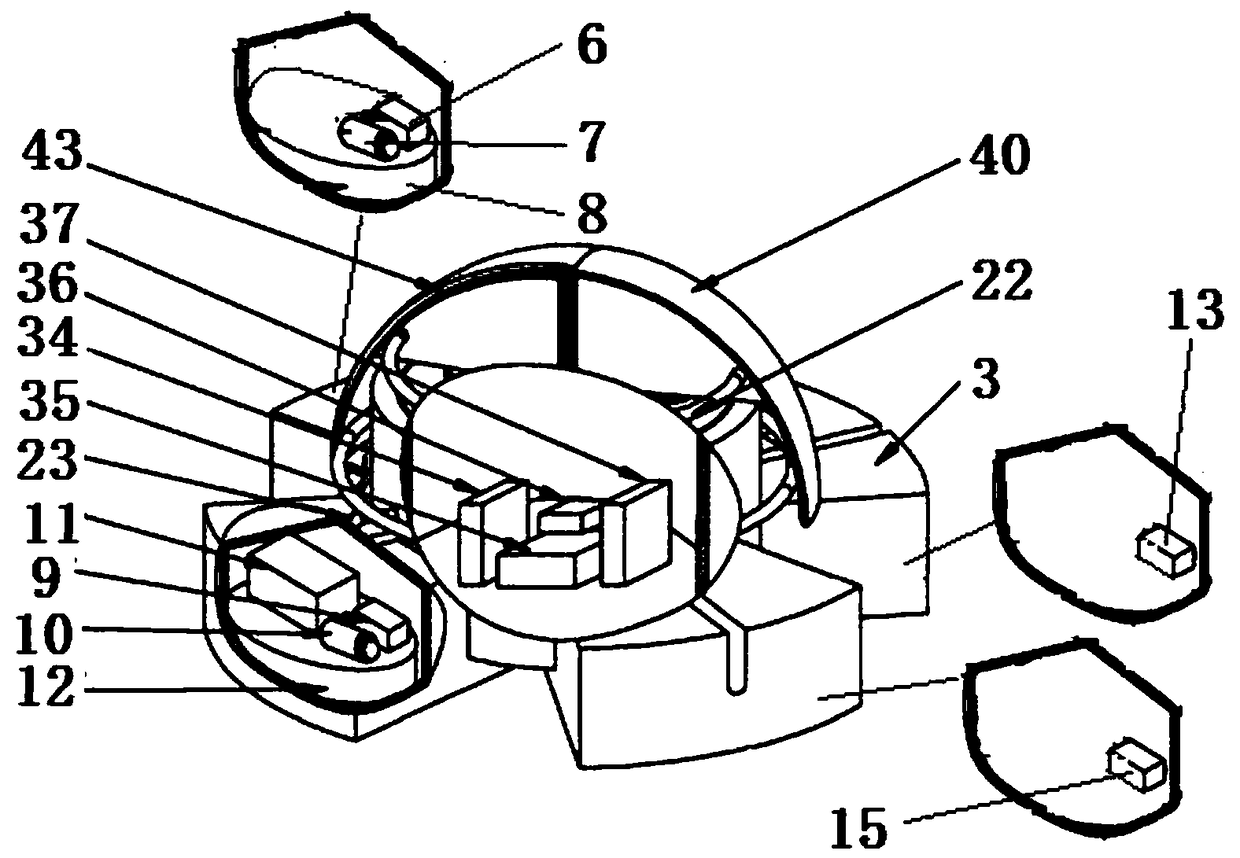

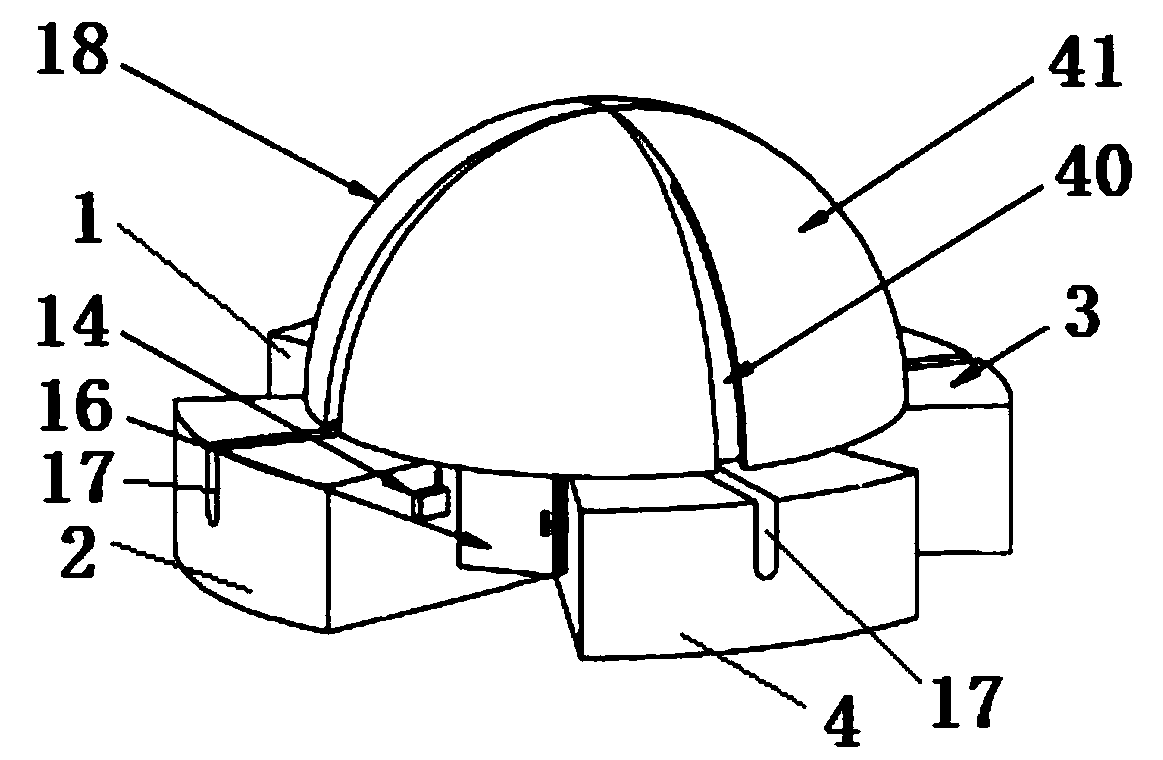

[0028] The main structure of the anticorrosive coating natural environment test and performance detection system involved in this embodiment includes No. 1 base 1, No. 2 base 2, No. 3 base 3, No. 4 base 4, control pile 5, and No. 1 control Unit 6, No. 1 water pump 7, Distilled water tank 8, No. 2 control unit 9, No. 2 water pump 10, Electrochemical workstation 11, Detection solution tank 12, No. 3 control unit 13, Signal receiver 14, No. 4 control unit 15, Control cabinet 16, chute 17, cleaning and drying detector 18, electrochemical performance detector 19, shape detector 20, physical performance detector 21, arc expansion device 22, direct connection expansion device 23 and sample holder 24 ; The cavity structure of No. 1 base 1, No. 2 base 2, No. 3 base 3 and No. 4 base 4 are equally spaced around and fixedly connected to the periphery of the control pile 5 of the cylindrical structure, and No. 1 base The base 1 is provided with a control unit 6, a water pump 7, and a distil...

Embodiment 2

[0035] Before starting the anti-corrosion coating natural environment test and performance detection system involved in this embodiment, the sample 68 with the screw hole 72 at the bottom is clamped in the sample holder 67, and then the sample 68 is tightened by the fixed electrode 64. Fixed on the rotating ring 65, the control cabinet 16 is used to set the longitude and latitude of the test site, the period of the atmospheric natural environment test and the period of the coating performance test.

Embodiment 3

[0037] The anticorrosive coating natural environment test and performance detection system involved in this embodiment enters the atmospheric natural environment test state after being started, the controller 35 drives the arc-shaped retractor 22 to drive the cleaning and drying detector 18, the electrochemical performance detector 19, and the shape The detector 20 is separated from the physical performance detector 21, and the controller 35 drives the directly connected retractor 23 to drive the cleaning and drying detector 18, the electrochemical performance detector 19, the shape detector 20 and the physical performance detector 21 to drop to one On base 1, base 2, 2, base 3, and base 4, the controller 35 controls the height adjustment rod 60 to raise the sample holder 24 to the set test height, and the controller 35 controls the angle The adjuster 62 automatically adjusts the angles of the rotating ring 65 and the center disk 66 in real time according to the longitude and la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com