Tunable film bulk acoustic resonator

A thin-film bulk acoustic wave and resonator technology, applied in the field of microelectronics, can solve the problems of FBAR performance impact, insufficient tuning, and complex circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] A tunable thin film bulk acoustic resonator in this embodiment adopts a cavity structure, which is simple in process, easy to integrate and suitable for mass production.

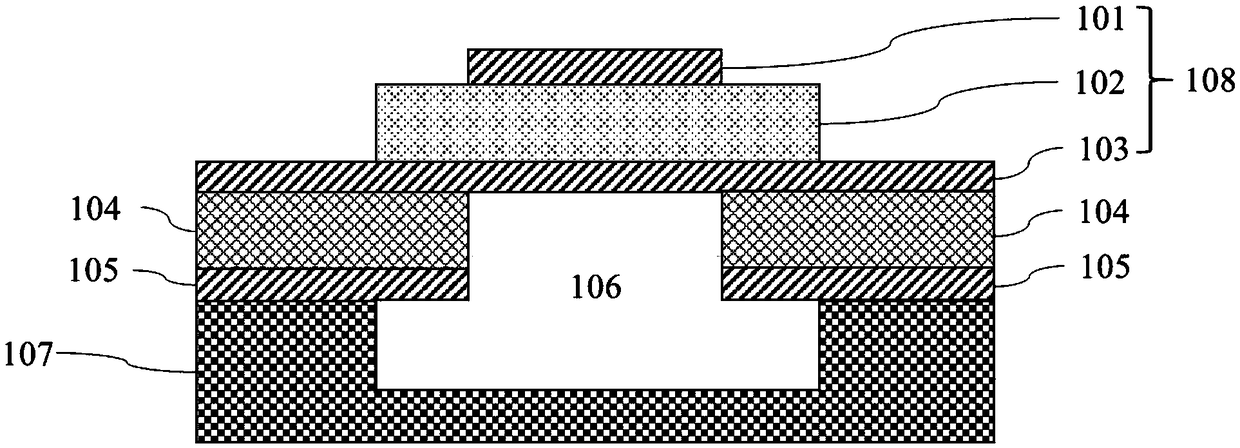

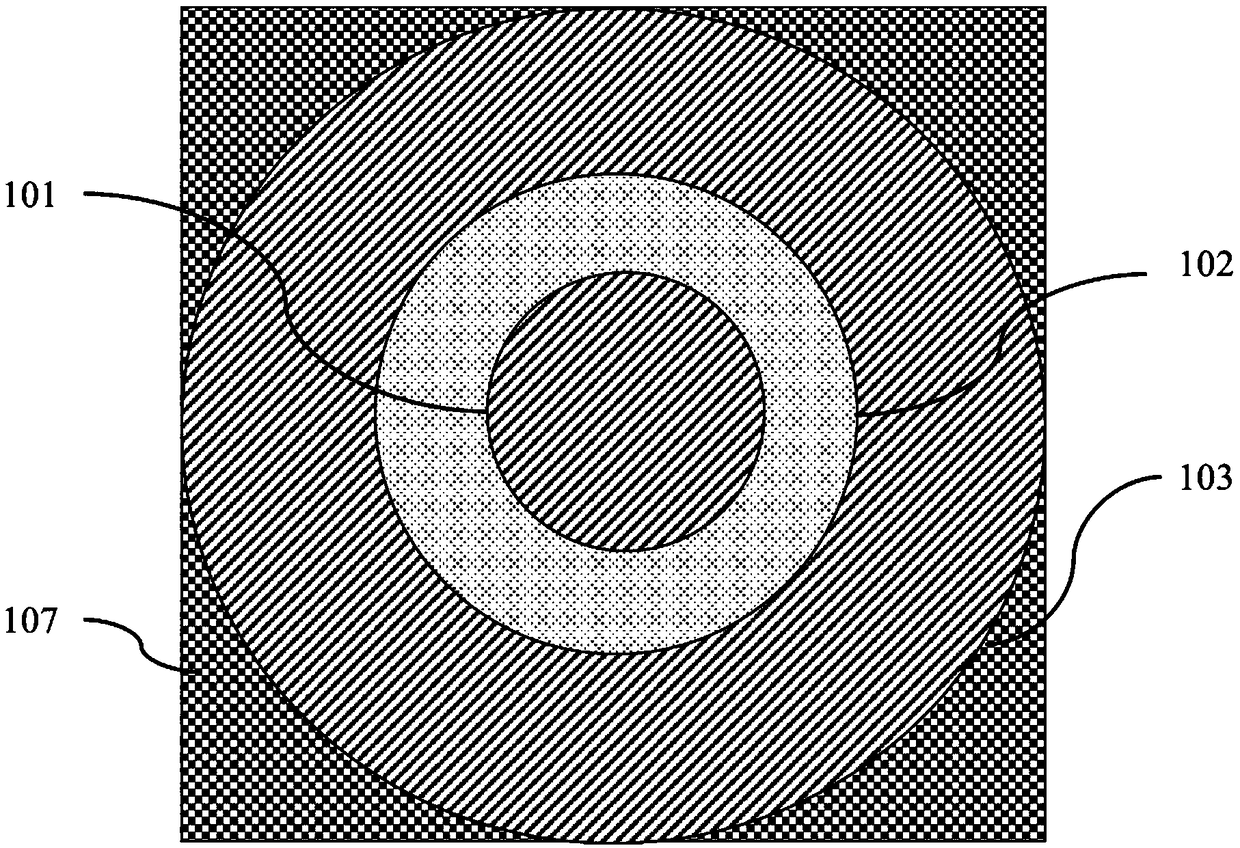

[0022] Such as figure 1 , figure 2 As shown, a tunable thin film bulk acoustic resonator includes a substrate 107 , a cavity 106 , a bottom electrode layer 105 , a tuning layer 104 , a middle electrode layer 103 , a piezoelectric layer 102 and an upper electrode layer 101 .

[0023] The upper electrode layer 101, the middle electrode layer 103 and the piezoelectric layer 102 between them form a piezoelectric oscillator stack 108, and their shapes can be circular, quadrangular, pentagonal, etc.; in this embodiment, a circular shape is used as an example Be explained.

[0024] The tuning layer 104 and the bottom electrode layer 103 can be all ring shapes such as circular rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com