Shoulder joint implant

An implant and shoulder joint technology, applied in the medical field, can solve the problems of troublesome rotator cuff tear treatment, high technical difficulty, and high price, and achieve the effect of restoring normal biomechanical properties, great application prospects, and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

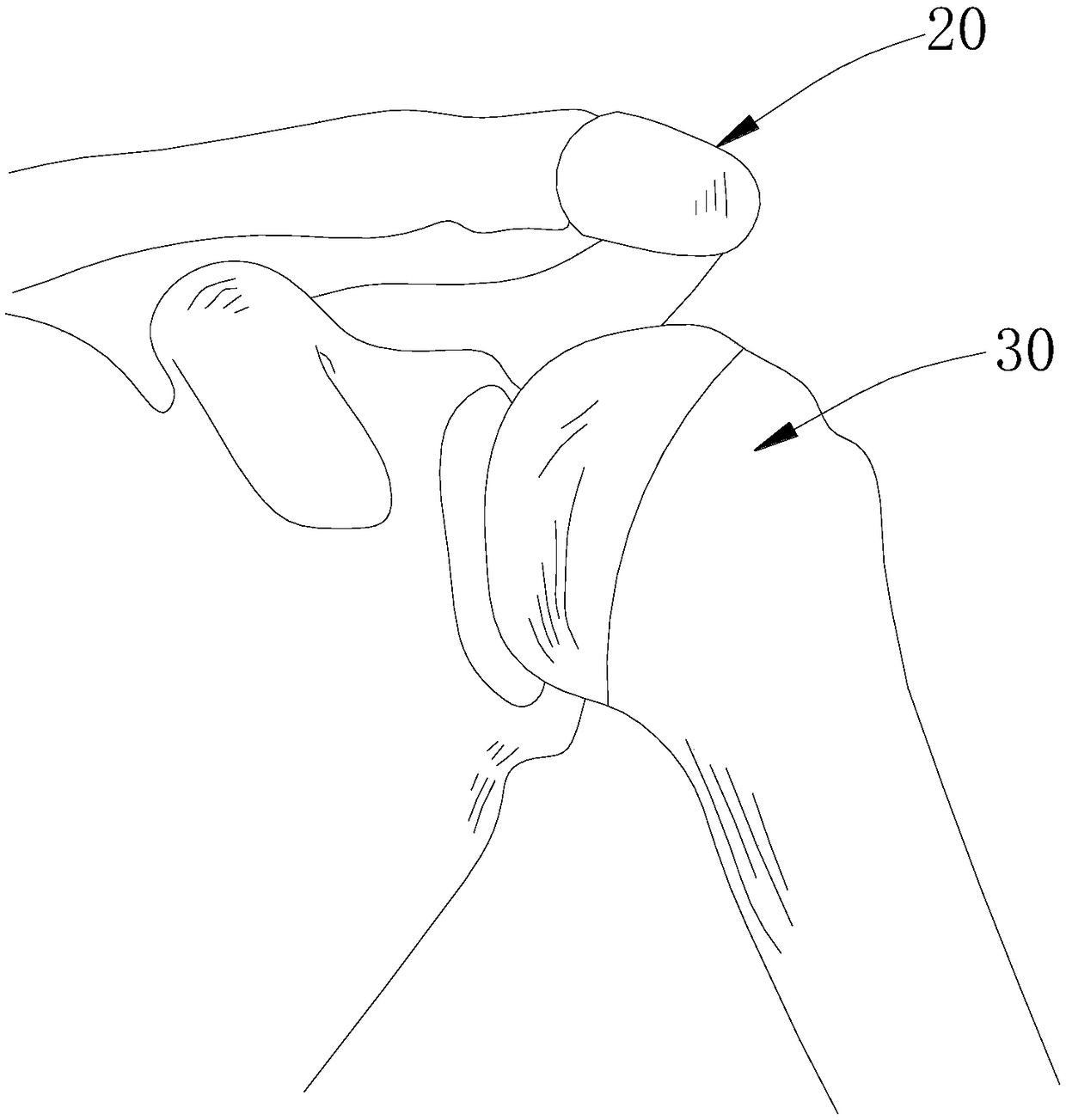

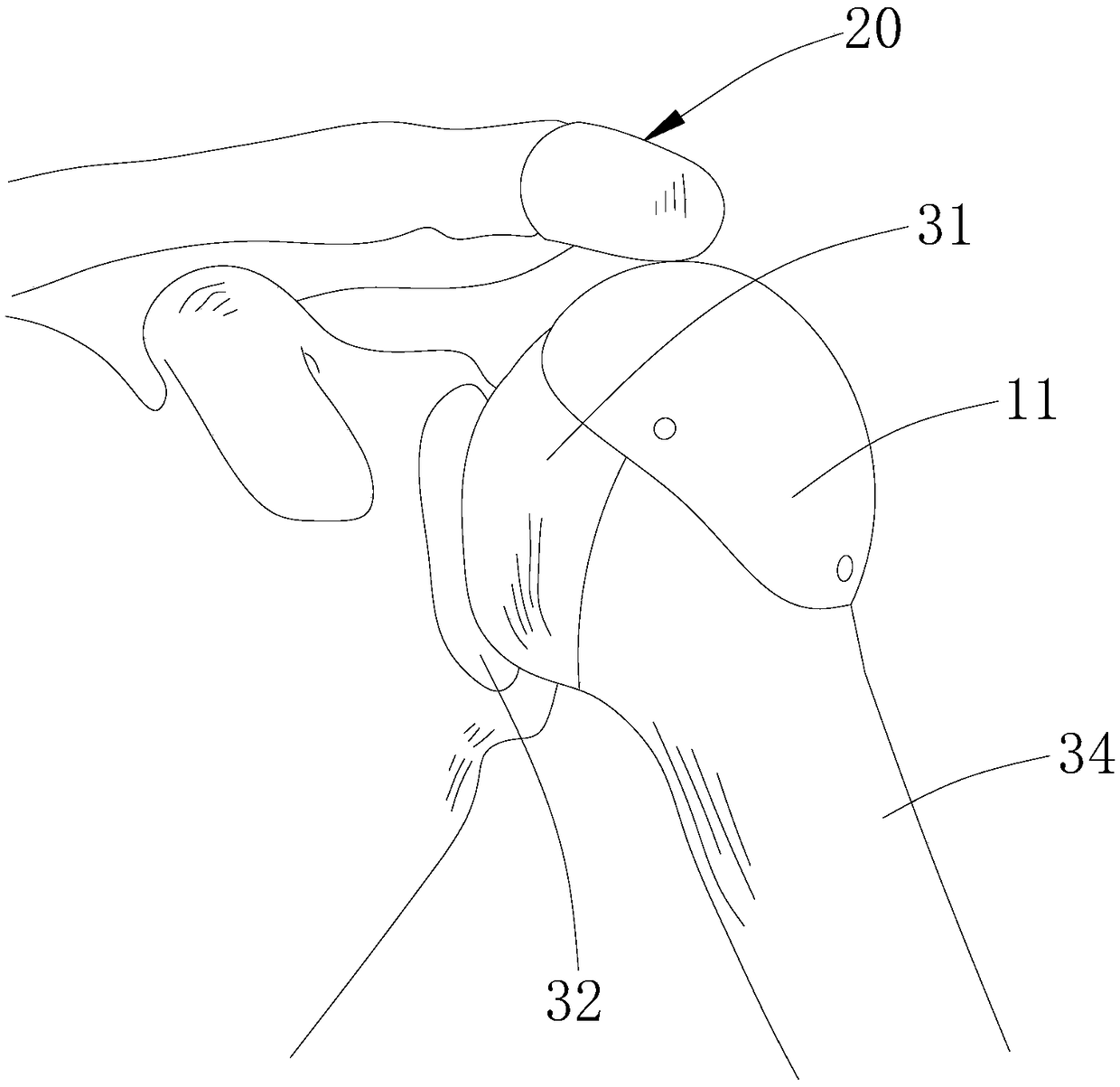

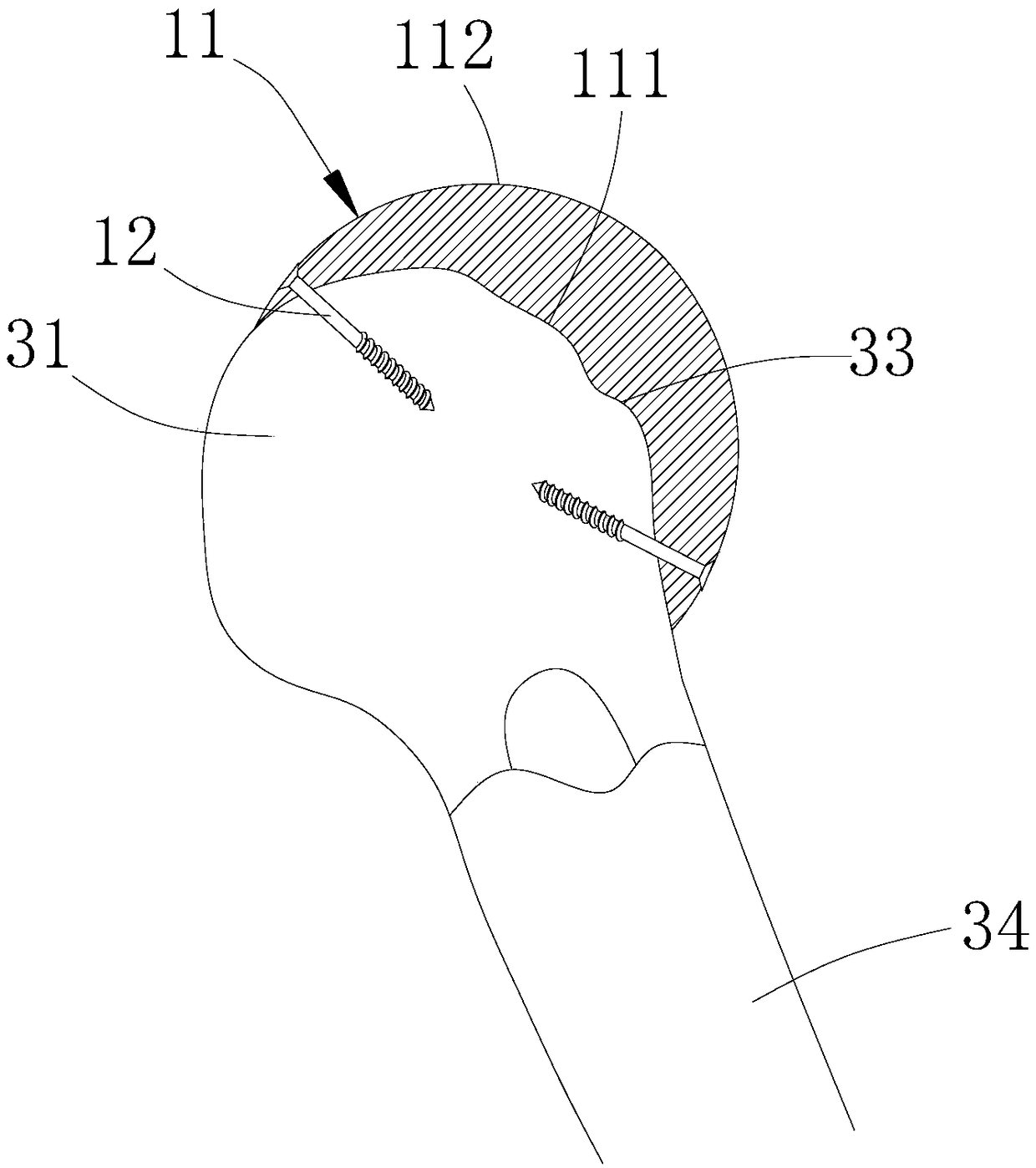

[0033] see Figure 1-3 , Embodiment 1 of the present invention provides a shoulder joint implant, which is used to maintain and increase the distance between the humeral head and the shoulder front and increase the distance between the greater tuberosity of the humerus and the shoulder front when the shoulder is abducted. The joint implant includes a solid cover 11 arranged between the shoulder 20 and the humerus end 30 and fixedly connected to the humerus end 30. The solid cover 11 has a first surface 111 fitted to the humerus end 30 and The second surface 112 disposed away from the humerus end 30 directly or indirectly abuts against the lower surface of the shoulder 20 .

[0034] In this design, through the solid cover 11 being fixedly connected to the humerus end 30, the second surface 112 of the solid cover 11 abuts against the lower surface of the shoulder 20 directly or indirectly. In this way, the distance between the humerus end 30 and the lower surface of the shoulde...

Embodiment 2

[0043] see Figure 5 The difference between the shoulder joint implant provided in Embodiment 2 of the present invention and the shoulder joint implant provided in Embodiment 1 is that the structure of the solid cover is different, specifically embodied in: the solid cover 21 provided in Embodiment 2 of the present invention Comprising an inner lining 213 and an outer lining 214, the inner lining 213 is a metal body fixed to the end of the humerus end 30 by bonding or screwing, the outer lining 214 is a ceramic body or a high molecular polyethylene body, and the inner side wall of the outer lining 214 It is fixed on the outer surface 215 of the inner liner 213 facing away from the humerus end 30 . With this design, by setting the metal lining, on the one hand, it can facilitate the fixing of the screw, on the other hand, it can make the solid cover more firmly fixed at the end of the humerus, reduce the possibility of its failure, and prolong the service life.

[0044] Prefer...

Embodiment 3

[0047] see Figure 6-11 The difference between the shoulder joint implant provided in the third embodiment of the present invention and the shoulder joint implant provided in the first embodiment is that the shoulder joint implant also includes a lower surface fixed on the shoulder front 20 to prevent shoulder The wear-resistant part 14 is worn by the front 20 , and the second surface 112 has an abutment portion abutting against the wear-resistant part 14 . It can be understood that since the humerus end 30 is in a relatively movable state relative to the shoulder 20, the abutting portion changes. With this design, the wear-resistant part 14 can prevent the shoulder 20 from being severely worn when the solid cover 11 is used for a long time, resulting in thinning of the shoulder 20 and prone to fracture of the shoulder 20 . Specifically, the wear-resistant piece 14 may be a ceramic layer or a high molecular polyethylene layer or a metal layer.

[0048] Preferably, the wear-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com