Gland segment grooving device

A technology of steam seals and arc sections, which is applied in the field of new mechanical processing devices, can solve the problems of laborious difficulty and time-consuming processing of steam seal rings, and achieve the effects of solving time-consuming processing, improving work efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

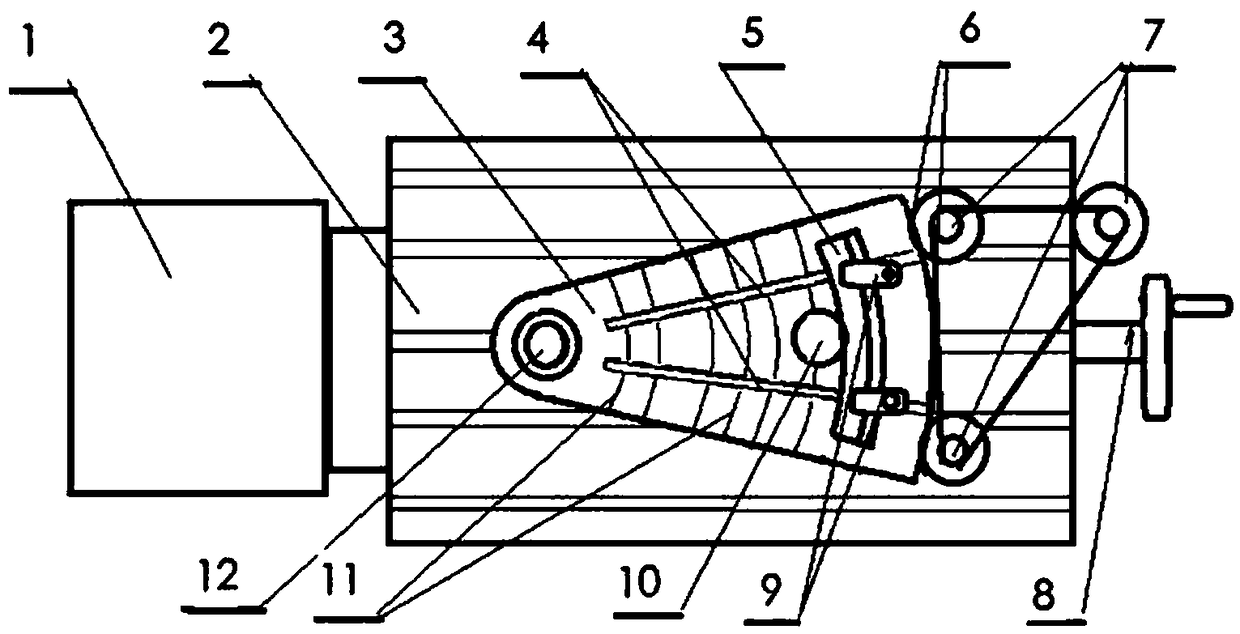

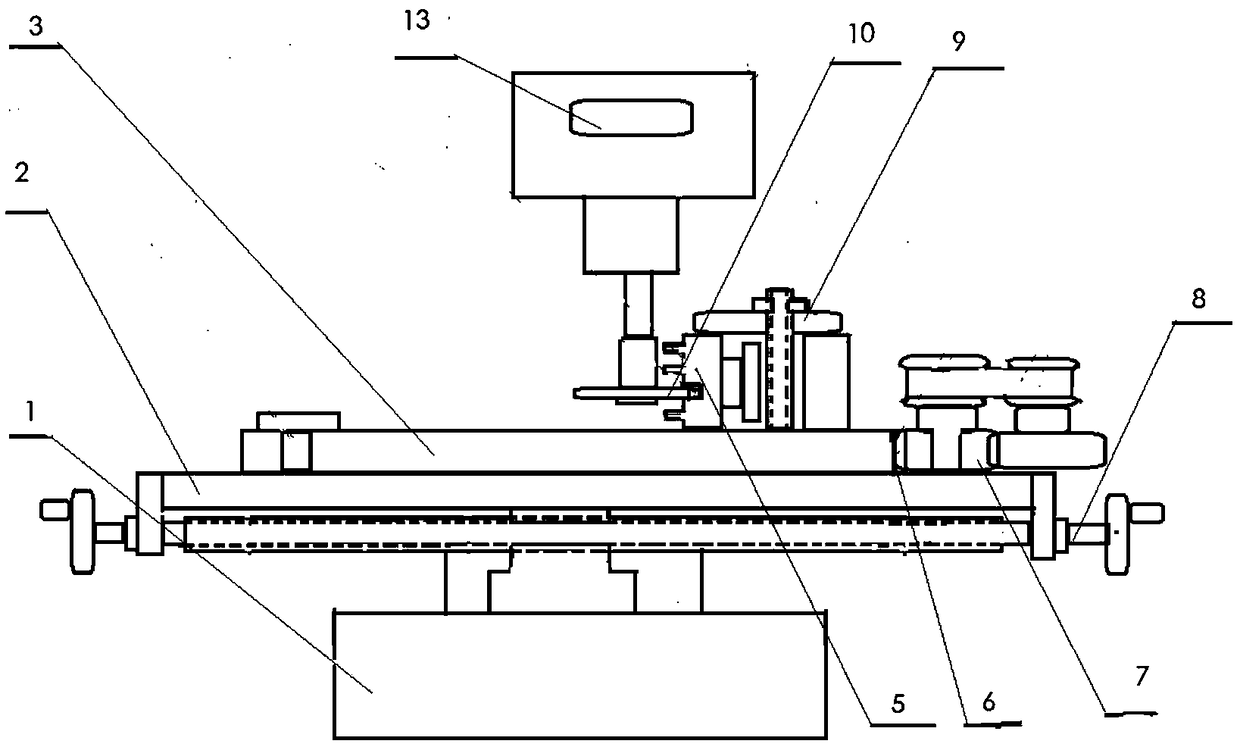

[0015] A slotting device for a steam seal arc section, comprising a drilling and milling machine 1, a worktable 2, a sector plate 3, a pressure plate groove 4, a steam seal arc section 5, teeth 6, a driving gear 7, an x-axis moving mechanism 8, and a steam seal pressure plate 9. Circular saw blade milling cutter 10, arc line 11, fixed bearing 12, displacement digital display meter 13; this kind of steam seal arc section slotting device is provided with a fan-shaped plate on the workbench 2 of the drilling and milling machine 1 3. A fixed bearing 12 is provided at the center of the head of the fan-shaped plate 3, so that the fan-shaped plate 3 can flexibly rotate around the bearing 12. With the bearing hole inside the fixed bearing 12 as the center of the circle, an interval 1- 2 mm densely arranged concentric arcs 11; on the left and right sides of the fan-shaped plate 3, a dovetail-shaped pressure plate groove 4 is symmetrically arranged, and the pressure plate groove 4 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com