Degassing device and method for hydrogen sulfide gas in drainage pipe network

A drainage pipe network and hydrogen sulfide technology, applied in chemical instruments and methods, water aeration, water pollutants, etc., can solve the problem of inability to efficiently remove hydrogen sulfide gas, and achieve a simple structure, high cost, and large dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

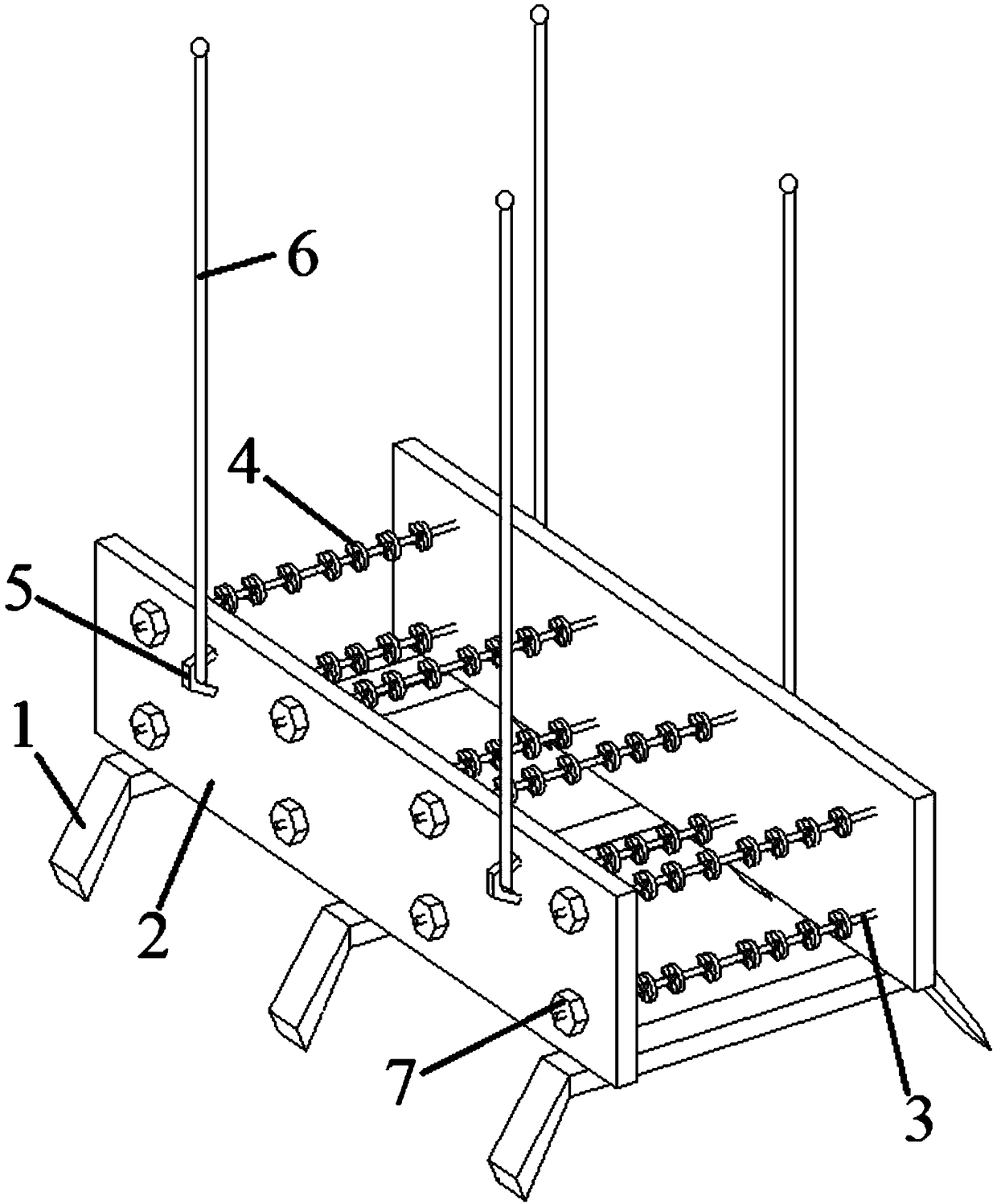

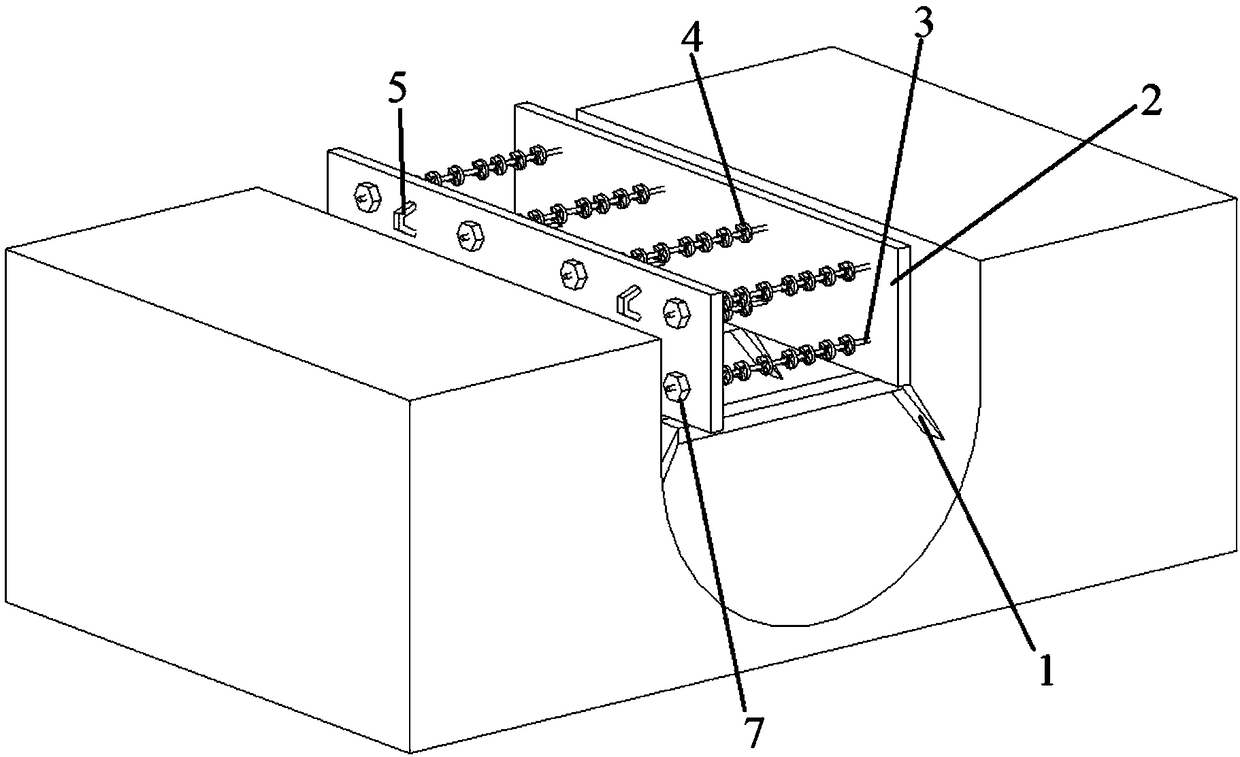

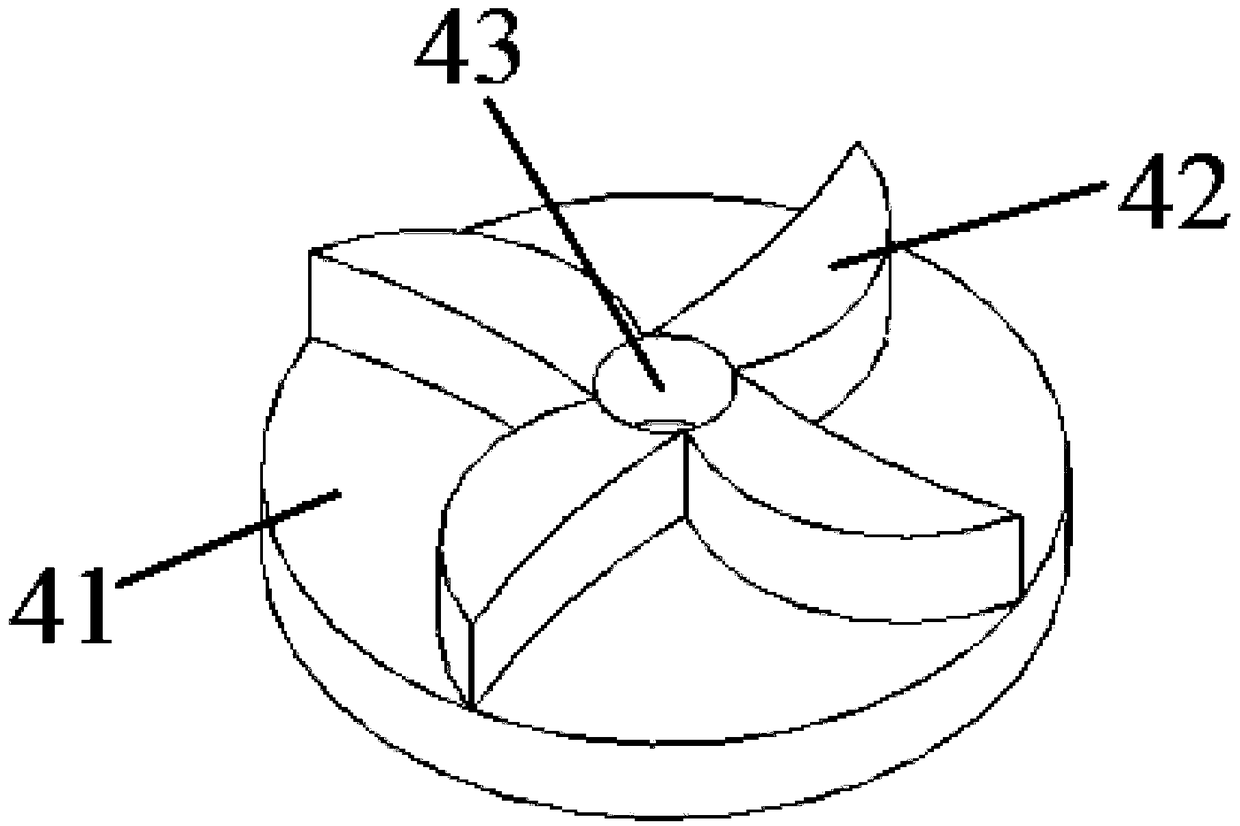

[0040] This embodiment provides a hydrogen sulfide gas degassing device for the drainage pipe network, such as Figure 1 to Figure 5 As shown, it includes a support foot 1, a side plate 2 installed on the support foot, a cross bar 3 installed on the side plate 2 and an impeller 4 installed on the cross bar 3;

[0041] The impeller 4 is made of iron-carbon filler.

[0042] This embodiment also provides a hydrogen sulfide gas degassing method for the drainage pipe network, which uses the hydrogen sulfide gas degassing device for the drainage pipe network as described above;

[0043] The hydrogen sulfide gas degassing device of the drainage pipe network is placed in the water body in the inspection well 8 of the drainage pipe network.

[0044] As a specific solution of the hydrogen sulfide gas degassing device for the drainage pipe network of this embodiment, two lifting lugs 5 are fixed on the side plate 2 of this embodiment, and a hanging piece 6 is hooked on the lifting lugs ...

experiment example

[0062] ①Determination of hydrogen sulfide removal efficiency

[0063] Add 800mL of domestic sewage to eight 1.5L beakers, add 100g of filler, and set the contact time of filler at 0.5min, 1min, 1.5min, 2min, 2.5min, 3min, 3.5min, 4min respectively. The numbers are a, b, c, d, e, f, g, h. Measure the content of hydrogen sulfide after sealed storage for 8 hours.

[0064] The experimental results are attached Figure 6 As shown, for 800ml of domestic sewage, when the filler is 100g and the reaction time is 7min, hydrogen sulfide will basically not be produced.

[0065] ② Calculation of the number of devices and the amount of filler used in the present invention

[0066] Set the diameter of the drainage pipe network to be 0.3m, the degree of fullness to be 0.5, the diameter of the inspection well to be 0.8m, the flow rate of sewage to be 0.6m / s, and the reaction contact time to be 1s. After calculation, the device of the present invention can be obtained on the basis of a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com